A 27000dwt chemical/product tanker construction process for stainless steel liquid cargo tanks

A product oil tanker, stainless steel technology, applied in the construction process of 27000DWT chemical/product oil tanker stainless steel liquid cargo tank, can solve the problems of difficult to guarantee the quality of the construction project, long construction period, high technical content, etc., to achieve safe production, improve work efficiency, The effect of ensuring the accuracy of closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

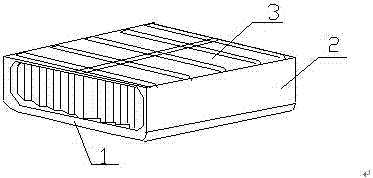

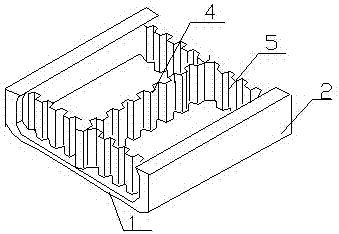

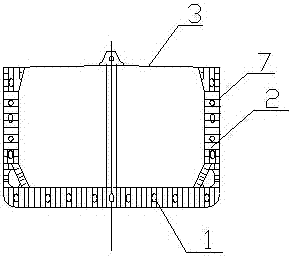

[0024] like Figure 1-Figure 3 As shown, the present invention discloses a 27000DWT chemical / product oil tanker stainless steel liquid cargo tank construction process. The liquid cargo tank adopts the technological process of small group erection, middle group erection, segmental, segmental general group and berth hoisting and closing, wherein segmental When dividing, the liquid cargo tank is reasonably divided into multiple annular three-dimensional segments, and the multiple annular three-dimensional segments include double bottom segment 1, side segment 2, deck segment 3, and longitudinal grooved bulkhead segment 4 , Transverse trough bulkhead segment 5.

[0025] The method of making each of the above sections is as follows:

[0026] The first step is to make each section: double bottom section 1 of the cargo hold is reverse-built with the inner bottom plate as the base surface, the side section 2 is built sideways with the outer plate 7 as the base surface, and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com