A kind of ultrapure water preparation device and its ultrapure water preparation method

A technology for preparing equipment and ultrapure water, which is applied in chemical instruments and methods, heating water/sewage treatment, water/sewage multi-stage treatment, etc. Due to the wide area and other problems, it achieves the effect of compact structure, high water quality, and convenient installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

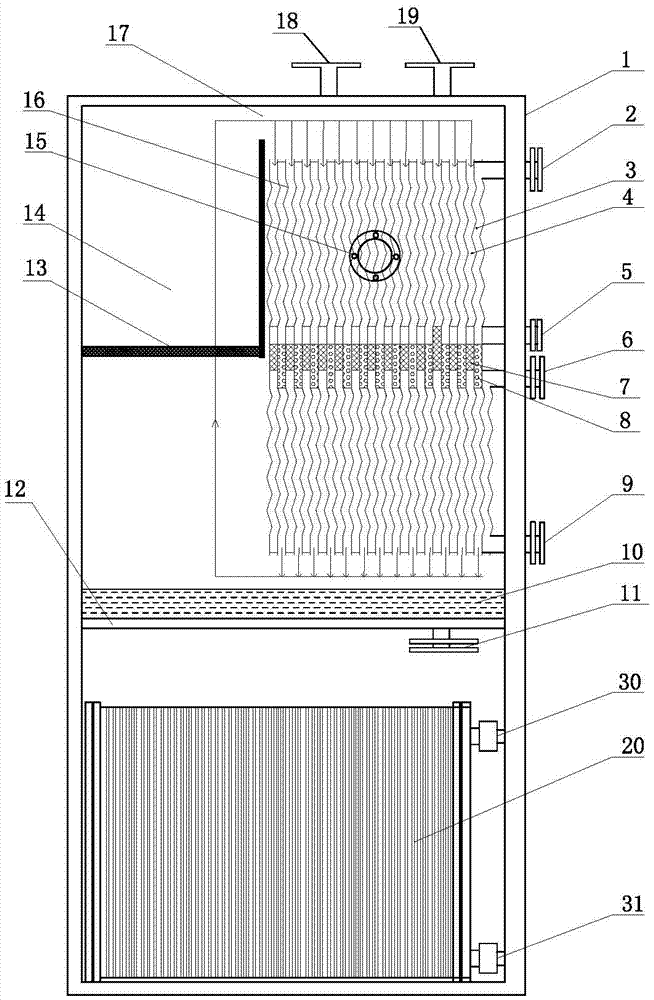

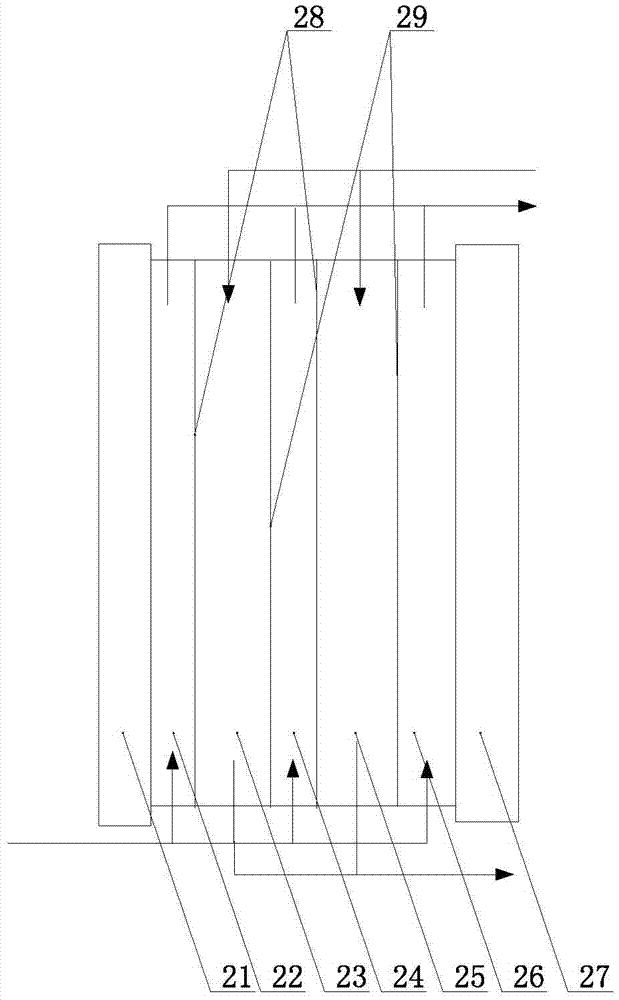

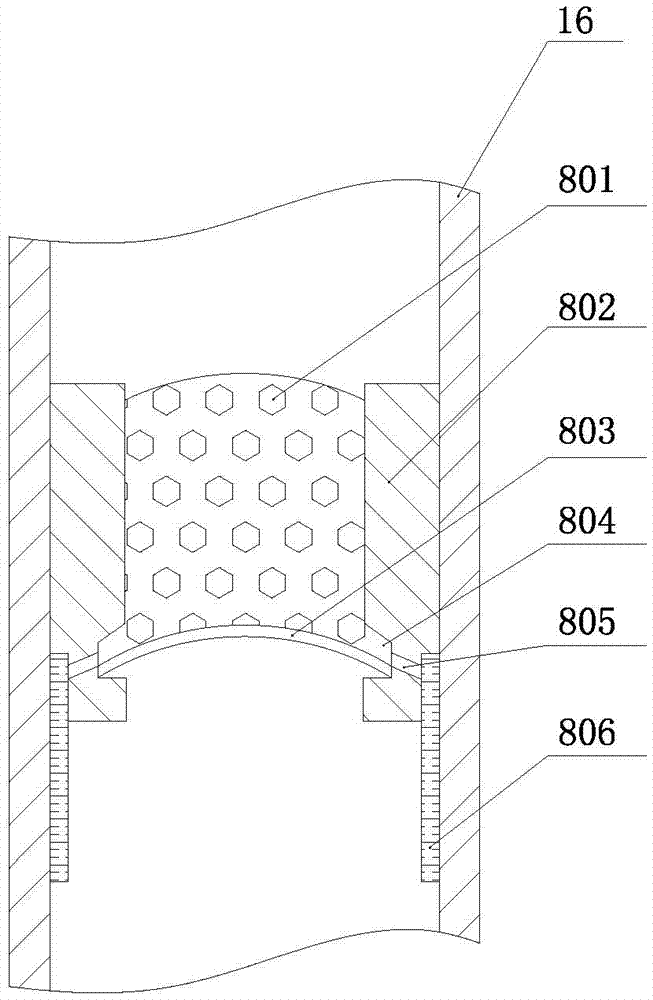

[0021] Such as figure 1 with figure 2 Shown is the ultrapure water preparation device of the present invention, comprising a housing 1, the housing 1 is separated into an upper chamber and a lower chamber by a middle partition 12 inside the housing 1, a first-stage fresh water system is arranged in the upper chamber, and the lower chamber There is a secondary fresh water system inside. The primary fresh water system includes a number of heat exchange plates 16 stacked horizontally. The adjacent heat exchange plates 16 are staggered to form the first heat exchange channel 3 and the second heat exchange channel 4. A collecting channel 1 is provided above the heat exchange channel 3, and the collecting channel 1 communicates with the cold water inlet pipe 2, and a collecting channel 2 is provided below the second heat exchange channel 4, and the collecting channel 2 is connected to the heat medium inlet 9 , the bottom of the first heat exchange channel 3 and the top of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com