Low-autogenous shrinkage and high-performance recycled concrete

A recycled concrete, high-performance technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem of high-performance recycled concrete's lack of in-depth autogenous shrinkage volume stability, concrete cracks, and aggregate inhibition Reduce the effect and other problems, to achieve the effect of improving volume stability, reducing spontaneous shrinkage, and reducing bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

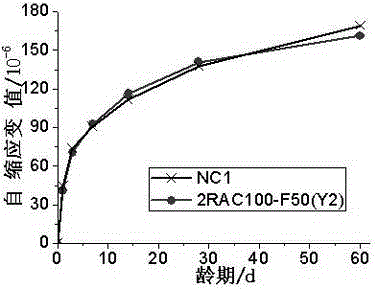

[0028] Each cubic meter of low autogenous shrinkage high-performance recycled concrete contains 500kg of cementitious materials (including 250kg of cement and 250kg of fly ash), 950kg of recycled coarse aggregate, 715kg of natural fine aggregate, 180kg of water, and 7.0kg of high-efficiency water reducer. The high-performance recycled concrete was prepared by the process of wrapping stone with clean slurry, and the slump of the obtained high-performance recycled concrete was 205mm, and the cubic compressive strength of 28 days was 52.4MPa. The autogenous shrinkage performance of the high-performance recycled concrete 2RAC100-F50 (Y2) in Example 1 and the ordinary concrete NC1 with the same proportion were tested respectively, and the results are shown in Table 2.

Embodiment 2

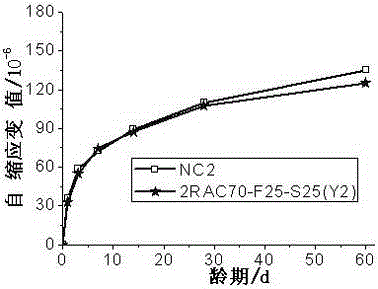

[0030]Each cubic meter of low autogenous shrinkage high-performance recycled concrete contains 400kg of cementitious materials (including 200kg of cement, 100kg of fly ash, and 100kg of slag), 345kg of natural coarse aggregate, 805kg of recycled coarse aggregate, 660kg of natural fine aggregate, water 160kg, superplasticizer 7.6kg. The high-performance recycled concrete was prepared by the process of wrapping stone with clean slurry, and the slump of the obtained high-performance recycled concrete was 180mm, and the cubic compressive strength of 28 days was 39.8MPa. The autogenous shrinkage properties of the high-performance recycled concrete 2RAC70-F25-S25 (Y2) in Example 2 and the ordinary concrete NC2 with the same proportion were tested respectively, and the results are shown in Table 2.

Embodiment 3

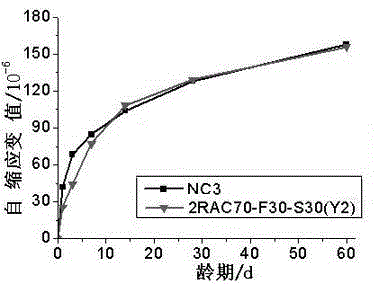

[0032] The high-performance recycled concrete with low spontaneous shrinkage per cubic meter contains 450kg of cementitious materials (including 180kg of cement, 135kg of fly ash, and 135kg of slag), 327kg of natural coarse aggregate, 764kg of recycled coarse aggregate, 669kg of natural fine aggregate, water 180kg, high-efficiency superplasticizer 9kg. The high-performance recycled concrete was prepared by the process of wrapping stone with clean slurry, and the slump of the obtained high-performance recycled concrete was 220mm, and the cubic compressive strength of 28 days was 37.7MPa. The autogenous shrinkage performance of the high-performance recycled concrete 2RAC70-F30-S30 (Y2) in Example 3 and the ordinary concrete NC3 with the same proportion were tested respectively, and the results are shown in Table 2.

[0033] Table 1 Raw material ratio and performance measurement results of test samples

[0034]

[0035] The autogenous shrinkage strain values of Examples 1-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com