High-weather-resistant glass fiber reinforced PC material and preparation method thereof

A technology of glass fiber and chopped glass fiber, which is applied in the field of weather-resistant glass fiber-reinforced PC materials and its preparation, can solve the problems of high material cost, high price, cumbersome process, etc., achieve great economic value and social value, and improve weather resistance Persistence, the effect of extending the range of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

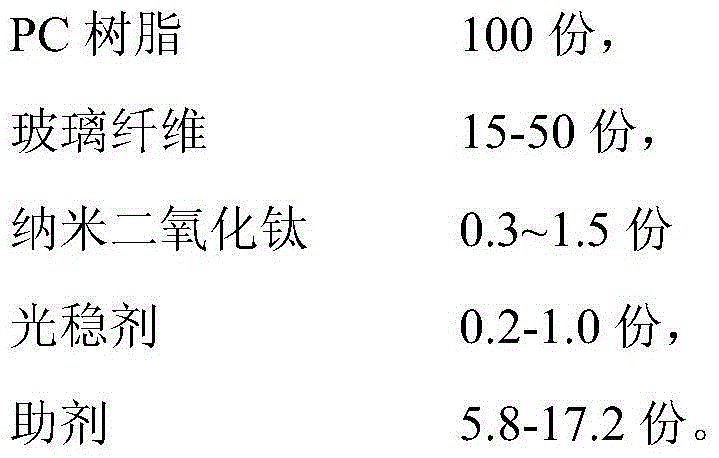

Method used

Image

Examples

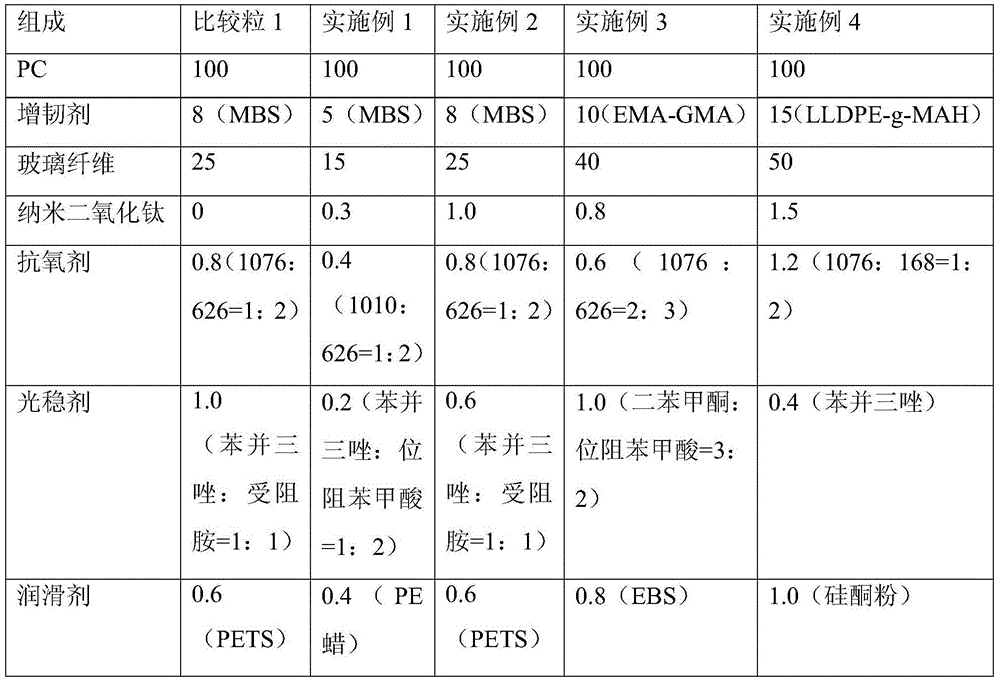

Embodiment 1

[0028] (1) Weigh PC, toughening agent, nano-titanium dioxide, antioxidant, light stabilizer, and lubricant according to the composition ratio in Table 1, and add them to the high-speed mixer for high-speed mixing. Control the speed of the high-mixer to 500rmp, and the mixing temperature at 80°C, mix for 3 minutes and mix well;

[0029] (2) Put the mixed material and glass fiber into the twin-screw extruder to extrude and granulate, and control the temperature of each zone (from the feeding port to the die head of the extruder) to 240°C, 250°C, 260°C, 275°C, 265°C ℃, the extruder strands can be cut into pellets to obtain glass fiber reinforced PC materials.

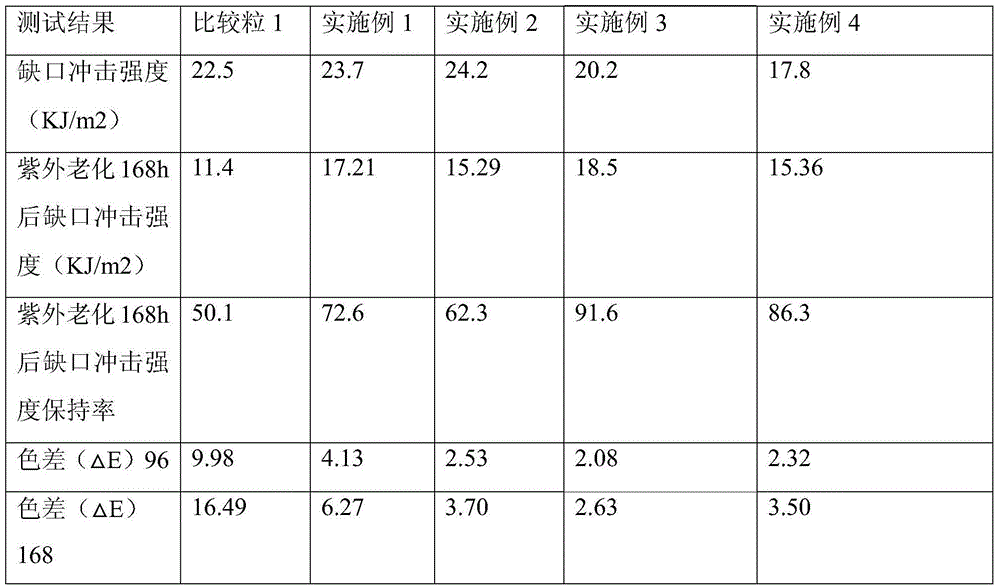

[0030] The above product was dried at 85° C. for 5 hours in a blast oven and then injection molded with an injection molding machine, and the injection molding temperature was 275° C. The extruded strips were placed at 50% relative humidity at 23°C for 24 hours before performance testing. The test results are shown in Ta...

Embodiment 2

[0032] (1) Weigh PC, toughener, nano-titanium dioxide, antioxidant, light stabilizer, and lubricant according to the composition ratio in Table 1, and add them to the high-speed mixer for high-speed mixing. Control the speed of the high-mixer to 700rmp, and the mixing temperature at 40°C, mix for 6 minutes and mix well;

[0033] (2) Put the mixed material and glass fiber into the twin-screw extruder to extrude and granulate, and control the temperature of each zone (from the feed port to the die head of the extruder) to 230°C, 240°C, 255°C, 270°C, 260°C ℃, the extruder strands can be cut into pellets to obtain glass fiber reinforced PC materials.

[0034] The above product was dried at 85° C. for 5 hours in a blast oven and then injection molded with an injection molding machine, and the injection molding temperature was 275° C. The extruded strips were placed at 50% relative humidity at 23°C for 24 hours before performance testing. The test results are shown in Table 1.

Embodiment 3-4

[0036] (1) Weigh PC, toughening agent, nano-titanium dioxide, antioxidant, light stabilizer, and lubricant according to the composition ratio in Table 1, and add them to the high-speed mixer for high-speed mixing. Control the speed of the high-mixer to 600rmp, and the mixing temperature at 60°C, mix for 10 minutes and mix well;

[0037] (2) Put the mixed material and glass fiber into the twin-screw extruder to extrude and granulate, and control the temperature of each zone (from the feeding port to the die of the extruder) to 220°C, 235°C, 250°C, 265°C, 260°C ℃, the extruder strands can be cut into pellets to obtain glass fiber reinforced PC materials.

[0038] The above product was dried at 85° C. for 5 hours in a blast oven and then injection molded with an injection molding machine, and the injection molding temperature was 275° C. The extruded strips were placed at 50% relative humidity at 23°C for 24 hours before performance testing. The test results are shown in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com