Automotive axle housing steel and preparation method thereof

A technology for axle housing steel and automobiles, which is applied in the field of steel plate manufacturing, can solve the problems of unfavorable welding performance and formability of steel plates, and achieve the effects of improving welding and forming performance, improving toughness and reducing ductile-brittle transition temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

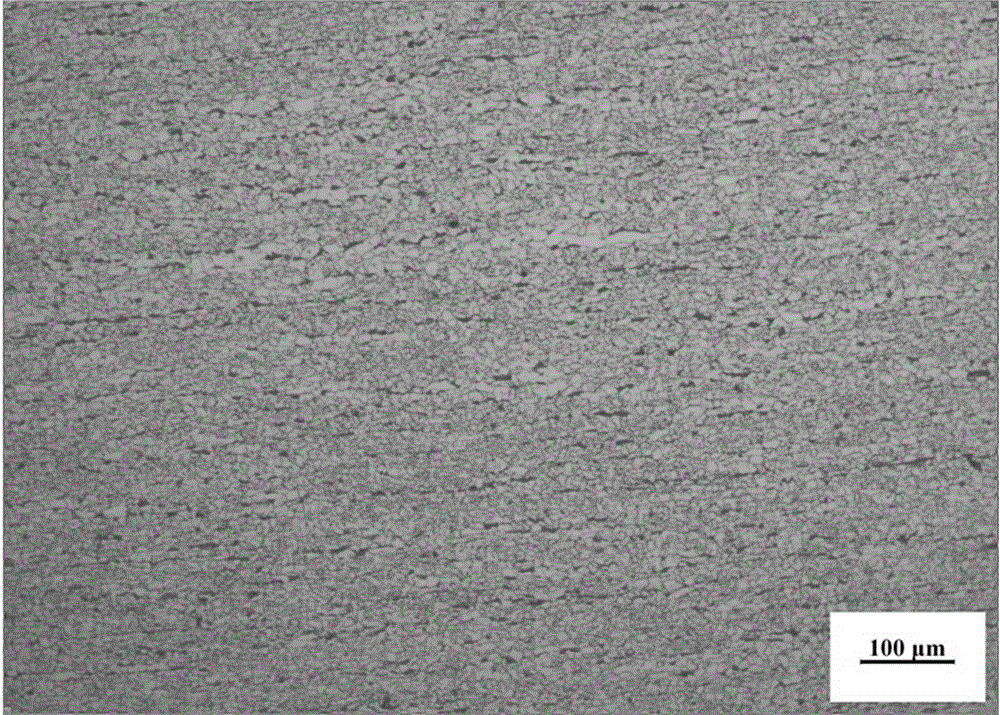

Image

Examples

Embodiment 1

[0038] (1) Carry out converter smelting. During the smelting process, oxygen is blown on the top of the converter, argon is blown on the bottom of the converter, carbon is drawn once, and NbFe is added during the tapping of the converter; After LF refining treatment, the casting slab with a thickness of 200mm is finally obtained by protective casting. The weight percentage of each component in the obtained slab is: C: 0.08%, Si: 0.30%, Mn: 1.40%, P: ≤0.014%, S : ≤0.002%, Als: 0.030%, Nb: 0.012%, Ti: 0.065%, the rest is Fe and unavoidable impurities.

[0039] (2) Cut the billet into the size required by the heating furnace and heat it in the heating furnace. The temperature of the heating section is 1220°C, the temperature of the soaking section is 1180°C, and the total heating time is more than 180min.

[0040] (3) Rough rolling is carried out on the slab processed in step (2), the rough rolling start temperature is 1050°C, the rolling passes are 5-7 passes, and an intermediat...

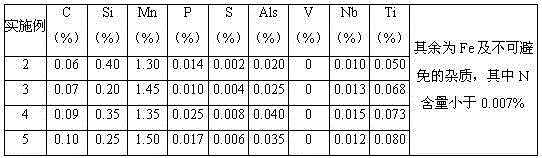

Embodiment 2~5

[0043]Steps (2) to (4) of Examples 2 to 5 are the same as in Example 1, only the content of each component in the cast slab obtained in Step (1) is changed, see Table 1 for specific changes.

[0044] Table 1

[0045]

Embodiment 6~9

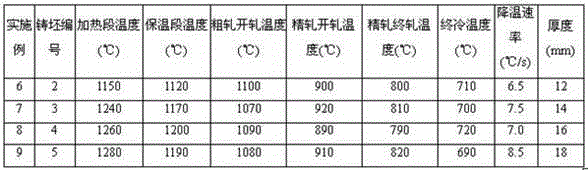

[0047] Get the cast slab obtained after the step (1) in Examples 6 to 9 for rolling operation, the cast slab number corresponds to its embodiment number, and the rolling operation is the same as the steps (2) to (4) in Example 1, only Change the rolling parameters in steps (2) to (4), see Table 2 for specific parameter changes.

[0048] Table 2

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com