Anti-counterfeit coating white cardboard containing dyed wood pulp fibers and production process thereof

A wood pulp fiber and production process technology, applied in the field of anti-counterfeiting coated white cardboard and its production technology, can solve the problems of huge investment, inconvenience, and impact on the application in the field of anti-counterfeiting packaging for anti-counterfeiting coated cardboard, and achieve good economic benefits and Environmental benefits, simple preparation process, and the effect of increasing the difficulty of imitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

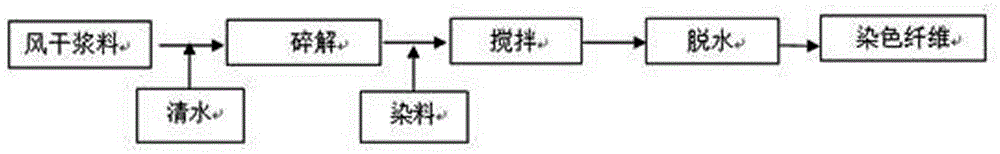

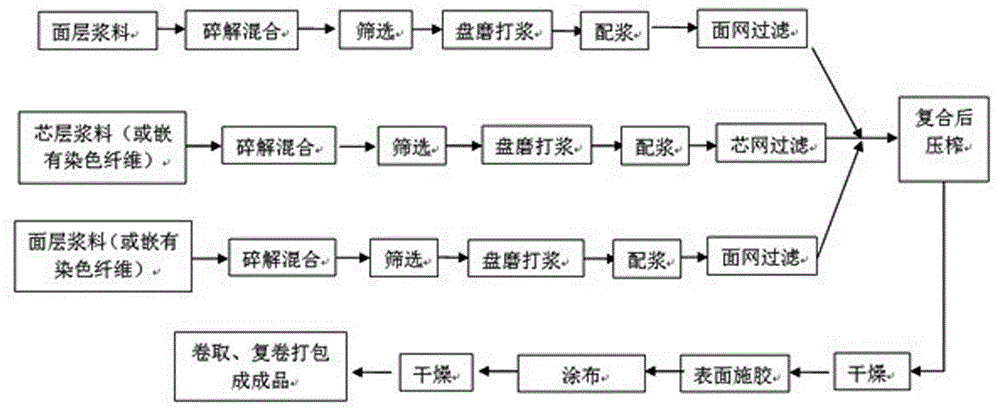

[0032] according to figure 1 In the steps shown, add water to disintegrate the air-dried bleached softwood kraft pulp according to the concentration of 3wt%, then add anionic direct violet dye according to 4wt% of the air-dried pulp, stir for 5min, let stand for 1min, and finally dehydrate for 10min to obtain Dyed wood pulp fibers; according to figure 2 In the steps shown, the pulp of the surface layer (percentage by weight: 70% of bleached hardwood kraft pulp, 30% of bleached softwood kraft pulp), the pulp of the core layer (percentage by weight: 50% of bleached hardwood kraft pulp %, 9.3% bleached softwood kraft pulp, 40% broken paper, 0.7% dyed wood pulp fiber) and bottom layer pulp (weight percentage: 90% bleached hardwood kraft pulp, 10% bleached softwood kraft pulp) Respectively go through pulper disintegration and mixing, screening, disk refiner refining, pulp mixing, and paper machine for papermaking; the surface layer slurry, core layer slurry and bottom layer slurr...

Embodiment 2

[0035] Add water to disintegrate the air-dried bleached softwood kraft pulp according to the concentration of 4wt%, then add anionic direct violet dye according to 4wt% of the air-dried pulp, stir for 5 minutes, then let it stand for 1 minute, and finally dehydrate for 10 minutes to obtain dyed wood pulp fibers; The pulp of the surface layer (percentage by weight: 70% of bleached hardwood kraft pulp, 30% of bleached softwood kraft pulp), the pulp of the core layer (percentage by weight: 55% of bleached hardwood kraft pulp, 55% of bleached softwood kraft pulp, Kraft pulp 20.1%, broken paper 24%, dyed wood pulp fiber 0.9%) and the bottom layer pulp (weight percentage: bleached hardwood kraft pulp 90%, bleached softwood kraft pulp 10%) respectively pass through the pulper Disintegration and mixing, screening, disc refiner refining, pulp blending, and sending to paper machine for papermaking; the pulp of the surface layer, the pulp of the core layer and the pulp of the bottom layer...

Embodiment 3

[0038] Add water to disintegrate the air-dried bleached softwood kraft pulp according to the concentration of 3wt%, then add anionic direct blue dye according to 3wt% of the air-dried pulp, stir for 5 minutes, let stand for 1 minute, and finally obtain dyed wood pulp fibers after dehydration for 10 minutes; The pulp of the surface layer (percentage by weight: 90% of bleached hardwood kraft pulp, 10% of bleached softwood kraft pulp), the pulp of the core layer (percentage by weight: 55% of bleached chemical thermomechanical pulp, bleached softwood kraft pulp 4.3% kraft pulp, 40% broken paper, 0.7% dyed wood pulp fiber) and the bottom layer pulp (weight percentage: bleached hardwood kraft pulp 70%, bleached softwood kraft pulp 30%) respectively through the pulper Disintegration and mixing, screening, disc refiner refining, pulp blending, and sending to paper machine for papermaking; the pulp of the surface layer, the pulp of the core layer and the pulp of the bottom layer are fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com