Inorganic veneer insulation decorative board and continuous production method thereof

A technology for thermal insulation decorative panels and production methods, which is applied in the field of building materials, can solve problems such as low production efficiency and cumbersome production processes, and achieve the effects of high production efficiency, strong controllability, and simplified procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

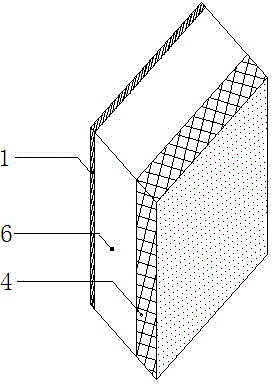

[0038] In this embodiment, the inorganic decorative surface thermal insulation decorative board includes the inorganic decorative surface material 4 for decoration and fire prevention, the thermal insulation layer 6 attached to the back of the inorganic decorative surface material and combined with the inorganic decorative surface material, and the thermal insulation layer 6 attached to the thermal insulation layer. Roll 1 on the other side.

[0039] The inorganic decorative surface material adopts marble veneer, and the specific operation steps of its production process are as follows:

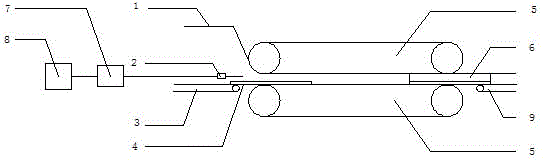

[0040] A continuous production line consisting of high / low pressure foaming machine system 7, front conveying platform 3, double track laminator system 5, coil uncoiling mechanism and pouring platform is adopted, and front conveying platform 3 and double track laminator system 5 are set. 1. The linkage speed of the coil uncoiling mechanism is 15m / s. Place a 0.695m×0.540m marble veneer on the ...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that the inorganic decorative surface material is made of aluminum-plastic plate veneer, and the specific operation steps of its production process are as follows:

[0043] Set the linkage speed of the front conveyor 3, the double-track laminator system 5, and the coil uncoiling mechanism to 4.5m / s, place the 1.2m×0.6m aluminum-plastic panel on the front conveyor 3, and adjust the gun The pressure of head 2 is 16MPa, the flow rate is 208g / s, and the ratio of material A to material B is 1:2.1. The polyurethane thermal insulation composite material with a material temperature of 24°C is evenly distributed on the aluminum-plastic panel. At this time, the polyurethane thermal insulation composite material penetrates into the aluminum The veneer of the plastic plate has micropores and begins to foam. It is brought by the front conveyor 3 into the double-track laminator system 5 with a height difference of 4 cm between...

Embodiment 3

[0045]The difference between this embodiment and Embodiment 1 is that the inorganic decorative surface material adopts flexible stone, and the specific operation steps of its production process are:

[0046] Set the linkage speed of the front conveyor 3, the double-track laminator system 5, and the coil uncoiling mechanism to 30m / s, place a 0.9m×0.73m flexible stone on the front conveyor 3, and adjust the pressure of the gun head 2 to 10MPa, the flow rate is 1500g / s, the ratio of material A to material B is 1:4.3, and the polyurethane thermal insulation composite material with a material temperature of 40°C is evenly distributed on the flexible stone. At this time, the polyurethane thermal insulation composite material penetrates into the micropores of the flexible stone material and begins to The entire foaming process is completed after the front conveying table 3 is brought into the double-track laminator system 5 with a height difference of 9 cm between the upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com