Ultraviolet light solidification soft pipe lining old pipeline repairing technology

An ultraviolet and ultraviolet lamp technology, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve the problems of increasing the thickness of the inner lining layer, the collapse of the inner lining layer, waste, etc., and achieve physical and mechanical performance improvement and saving. Energy and materials, the effect of ensuring the first time success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

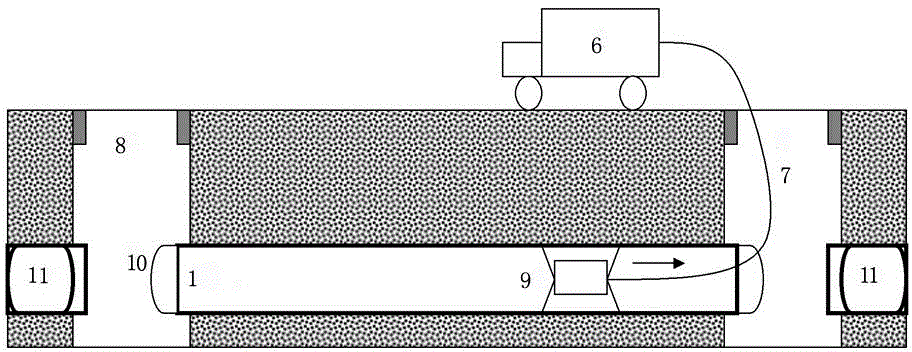

[0031] A process for repairing old pipelines with ultraviolet curing hose linings, comprising the following steps: a. on-site survey; b. production of glass fiber-lined hose semi-finished products in a workshop; c. on-site lining construction.

[0032] The site investigation step includes measuring the inner diameter of the pipeline to be repaired, measuring the length of the pipeline to be repaired and observing other conditions on the construction site.

[0033] The steps of making the semi-finished glass fiber lined hose in the workshop are as follows:

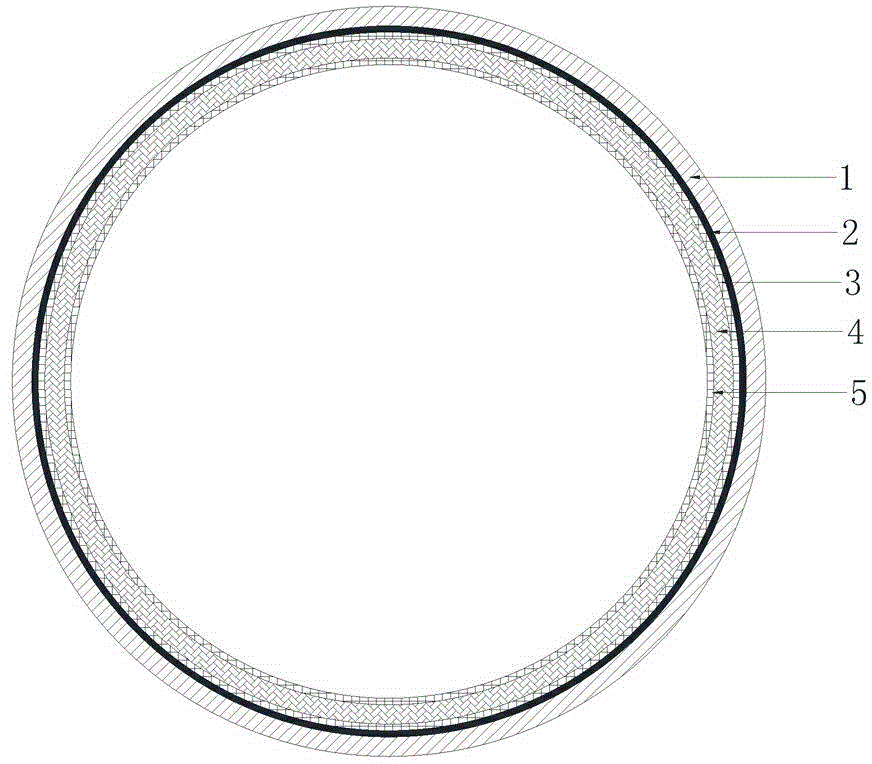

[0034] (1) According to the on-site investigation, the inner diameter and length of the pipeline to be repaired are obtained, and the PE shading film, PET outer isolation film and PET inner isolation film, glass fiber cloth and glass fiber chopped mat are cut according to the measured size in the workshop;

[0035] (2) The glass fiber cloth and the glass fiber chopped strand mat are sewed into a cylindrical shape in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com