Electric connecting structure and assembling method of LED lamp panel and power panel and lamp

A technology of LED light board and electrical connection structure, applied in the direction of light source, lighting device, point light source, etc., can solve the problems of low wire efficiency, false wire welding, wire aging, etc., to improve welding efficiency, improve quality, and facilitate welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

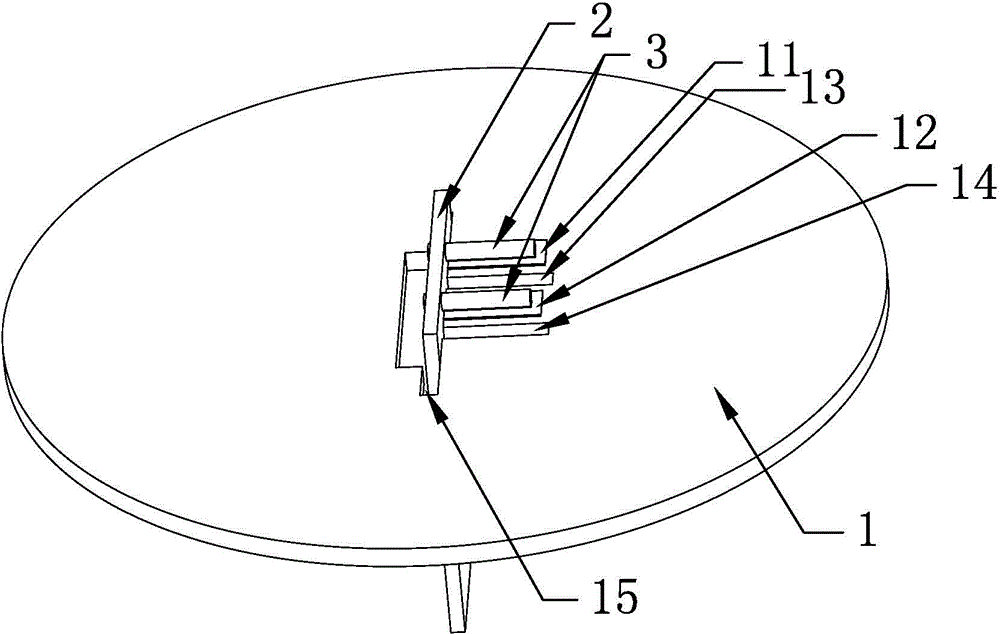

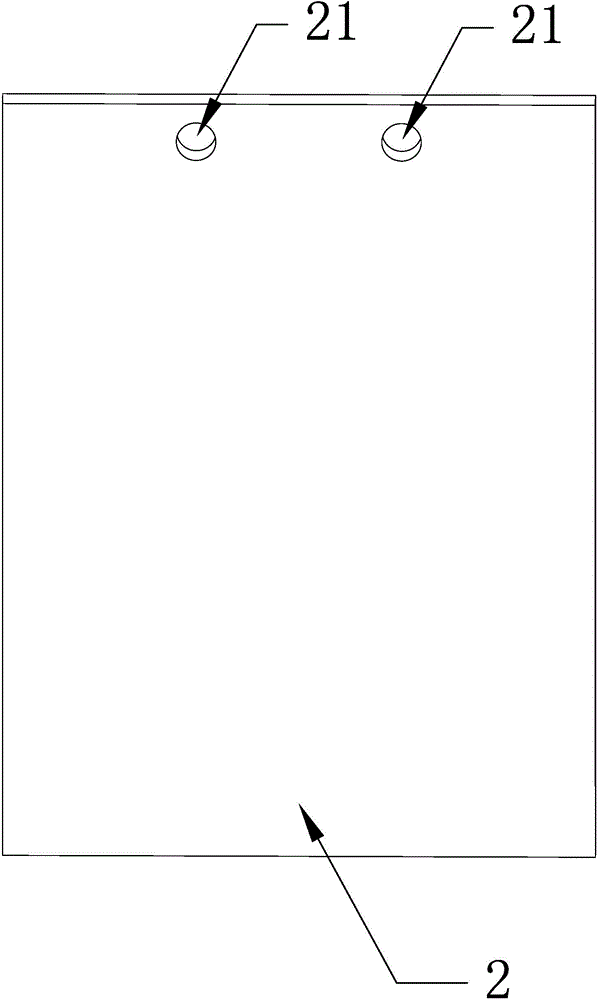

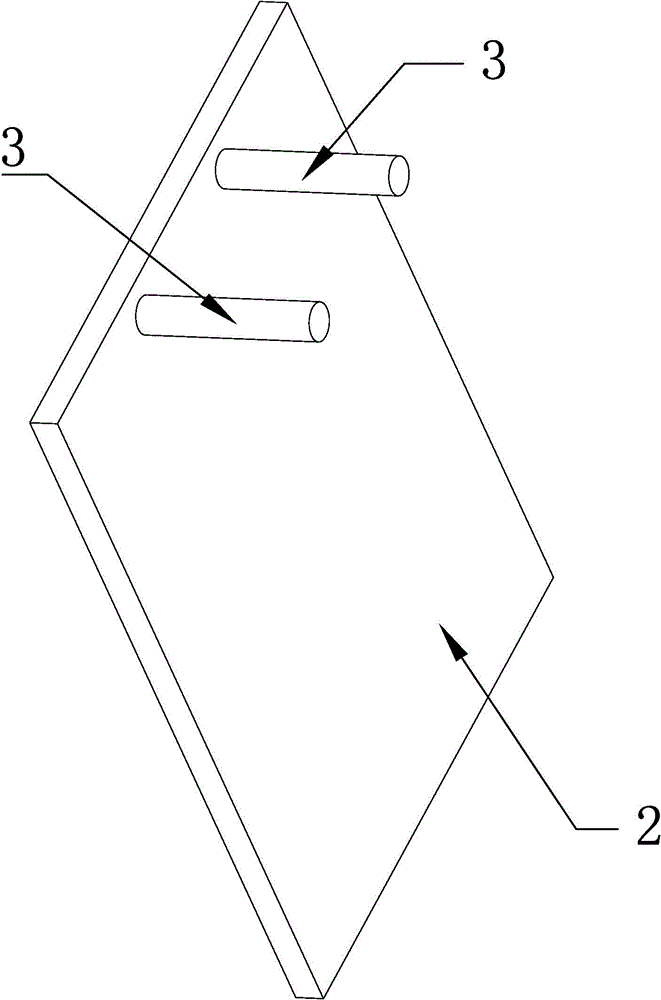

[0049] A kind of electrical connection structure of LED lamp board and power supply board of this embodiment, such as Figure 1 to Figure 4 As shown, it includes an LED lamp board 1 and a power board 2, and also includes two conductive pins 3; the LED lamp board 1 is provided with two patch pads for power supply input, and the power board 2 is provided with a power supply output Two soldering jacks 21, one end of the two conductive pins 3 are respectively welded to the two patch pads of the LED lamp board 1, and the other end of the two conductive pins 3 is connected to the power board 2 The two soldering jacks 21 are soldered.

[0050] This embodiment proposes for the first time that the electrical connection between the two circuit boards is completed through the combination of patch welding and plug-in welding. By using the conductive pin 3 to realize the electrical connection between the LED lamp board 1 and the power supply board 2, only the The two ends of the conductiv...

Embodiment 2

[0062] The electrical connection structure of an LED lamp board and a power board in this embodiment is different from the structure of Embodiment 1 in that: the LED lamp board is provided with two welding jacks for power supply input, and the power board is provided with The two patch pads for the output of the power supply, one end of the two conductive pins are respectively welded to the two welding sockets of the LED lamp board, and the other ends of the two conductive pins are connected to the two soldering holes of the power board. A patch pad soldering.

[0063] This structure is simpler and quicker when soldering conductive pins.

Embodiment 3

[0065] This embodiment provides an assembly method of the electrical connection structure of the LED lamp board and the power board of Embodiment 1, which includes the following steps for the case where the power board is vertically installed on the LED lamp board:

[0066] Step 1: Solder one end of the two conductive pins 3 to the two welding jacks 21 of the power board 2 respectively;

[0067] Step 2: Put the other ends of the two conductive pins 3 in Step 1 from the back of the LED light board 1 to the front (the front refers to the side of the LED light board 1 with LED lamp beads) from the first through hole 13 and the second through hole 13 respectively. The two through holes 14 pass through the LED lamp board 1, and the two conductive pins 3 are moved sideways to the first pad 11 and the second pad 12;

[0068] Step 3: Solder the other ends of the two conductive pins 3 to the first pad 11 and the second pad 12 .

[0069] In this embodiment, the two conductive pins 3 we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com