Cooling system of heating power device

A technology of heating power and cooling system, applied in cooling/ventilation/heating renovation, refrigerators, refrigeration components, etc., can solve the problems of large cooling load demand, poor regulation of cooling fans, loud fan noise, etc., to achieve stable system operation Reliable, long operating life, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

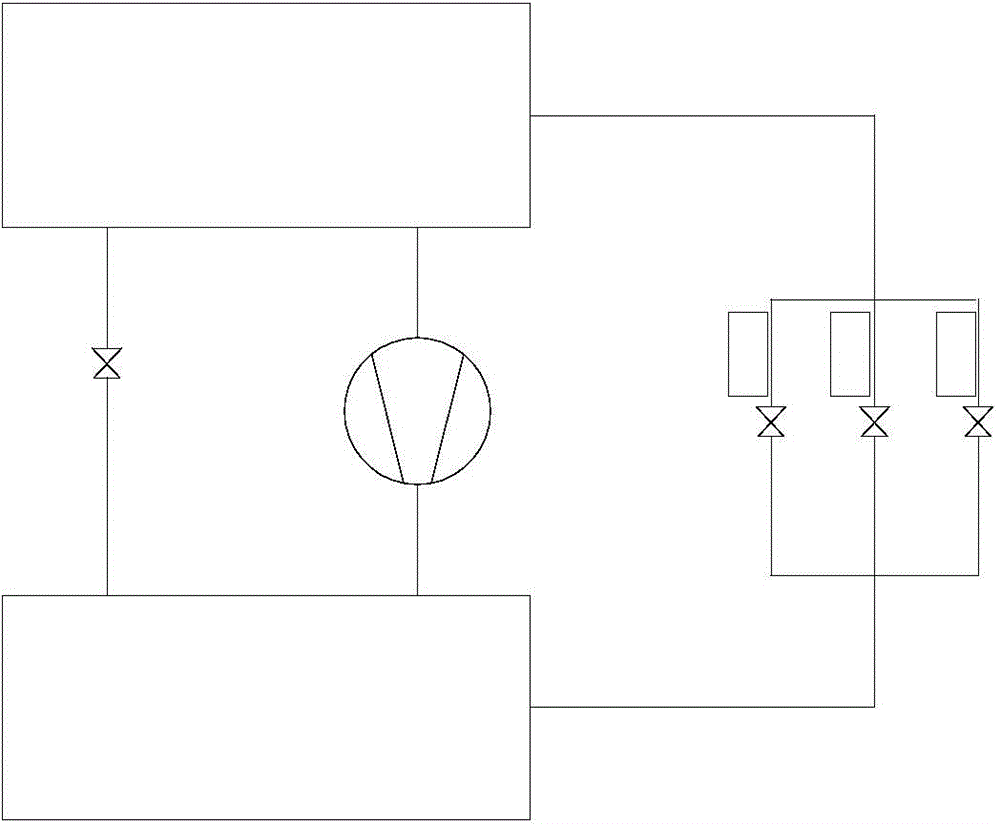

Image

Examples

Embodiment Construction

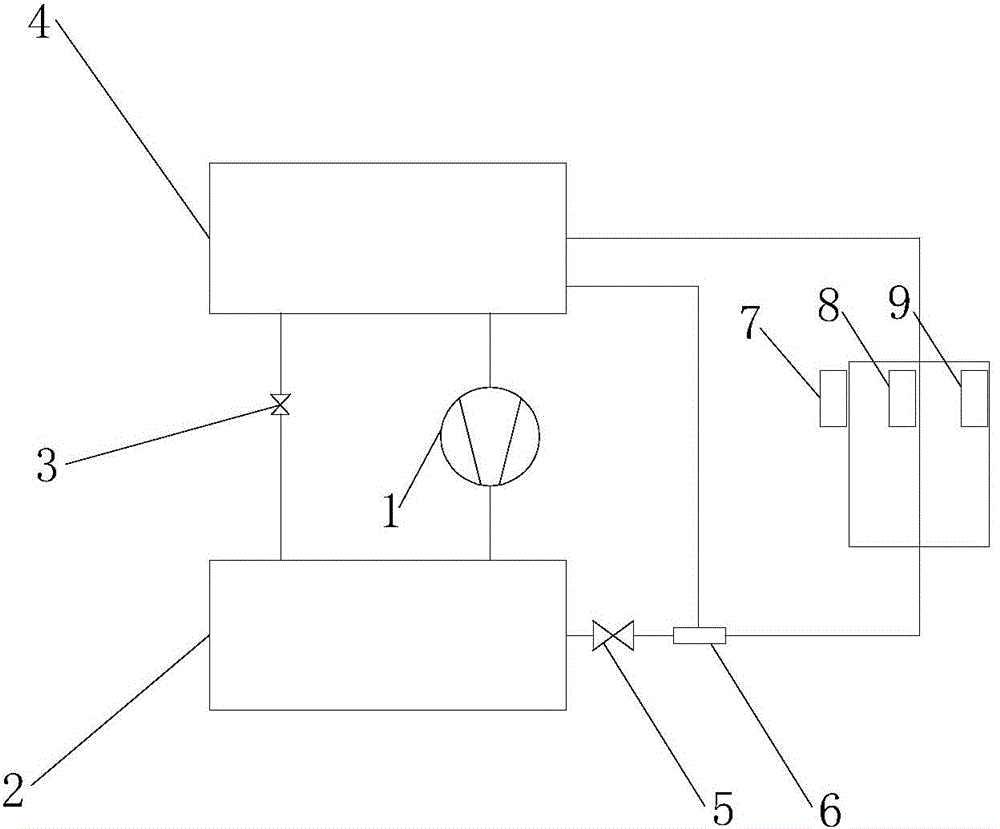

[0022] Such as figure 2 As shown, the present invention provides a heating power device cooling system, including an air-conditioning unit, the air-conditioning unit includes a compressor 1, a condenser 2, a throttling component 3 and an evaporator 4, and also includes an ejector 6, so The second refrigerant outlet of the condenser 2 is connected to the high-pressure inlet of the ejector 6, the liquid refrigerant outlet of the evaporator 4 is connected to the low-pressure inlet of the ejector 6, and the outlet of the ejector 6 is connected to the evaporator 4 The second suction port or the suction port of compressor 1 is connected, the pipeline between the outlet of ejector 6 and the second suction port of evaporator 4 or the outlet of ejector 6 and the suction port of compressor 1 There is a heat conduction relationship between the pipeline and the heating power device. In this embodiment, the outlet of the ejector 6 is connected to the second suction port of the evaporator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com