Vitrification freezing carrier system

A vitrification freezing and carrier system technology, applied in the field of carrier systems, can solve problems such as inconvenience in operation, and achieve the effects of saving floor space, increasing ease of use, and reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

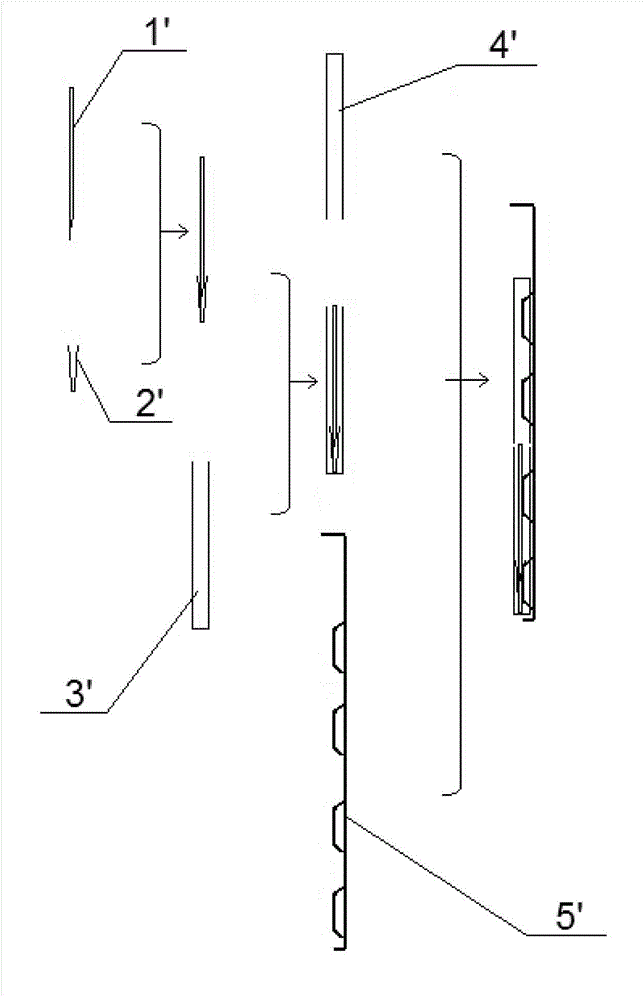

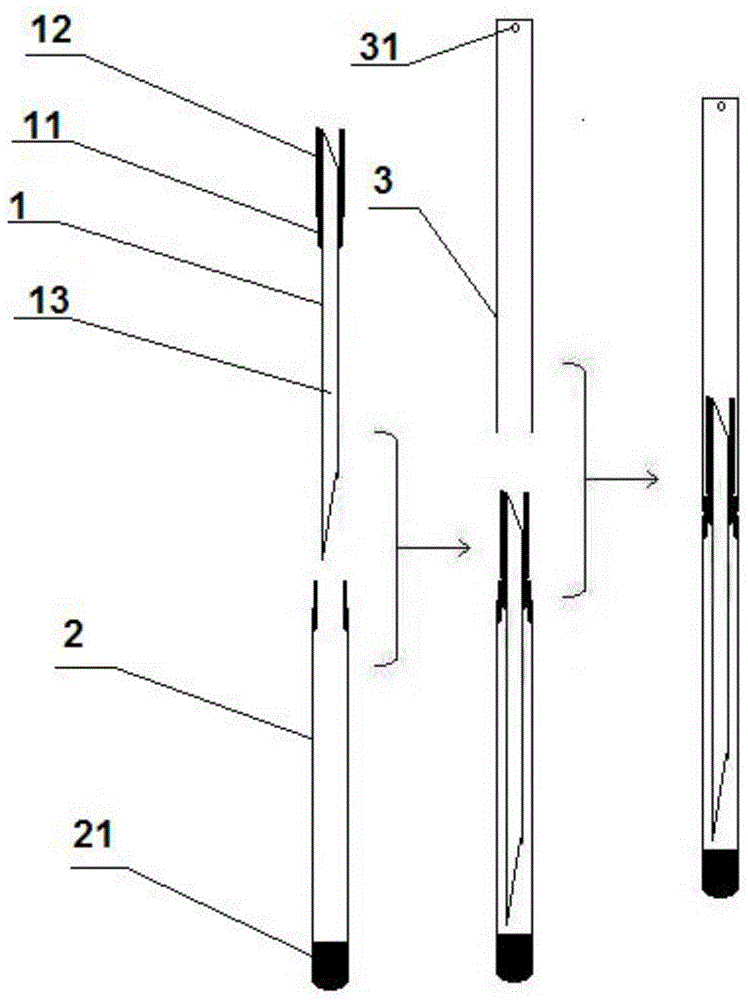

[0051] The vitrification carrier system provided in this embodiment includes a freezing rod 1, a freezing rod sleeve 2 and an extension sleeve 3, wherein the outer diameter of the freezing rod sleeve 2 is increased to directly serve as a protective tube.

[0052] The freezing rod 1 comprises a rod body, the rod body is composed of a lower extension 11 and an upper handle 12, and the lower end of the extension 11 is connected with a frozen storage sheet 13, which is a strip-shaped small piece whose transverse direction is a circle Arc-concave, for example, it can be a long strip-shaped piece formed by regularly cutting the side wall of a thin-walled transparent or translucent plastic tube in the longitudinal direction;

[0053] The freezing rod casing 2 is a hollow structure with a closed top, and an opening connecting the hollow structure with the external environment is provided at the upper end; Inside the hollow structure, a loading unit is formed.

[0054] The outer diame...

Embodiment 2

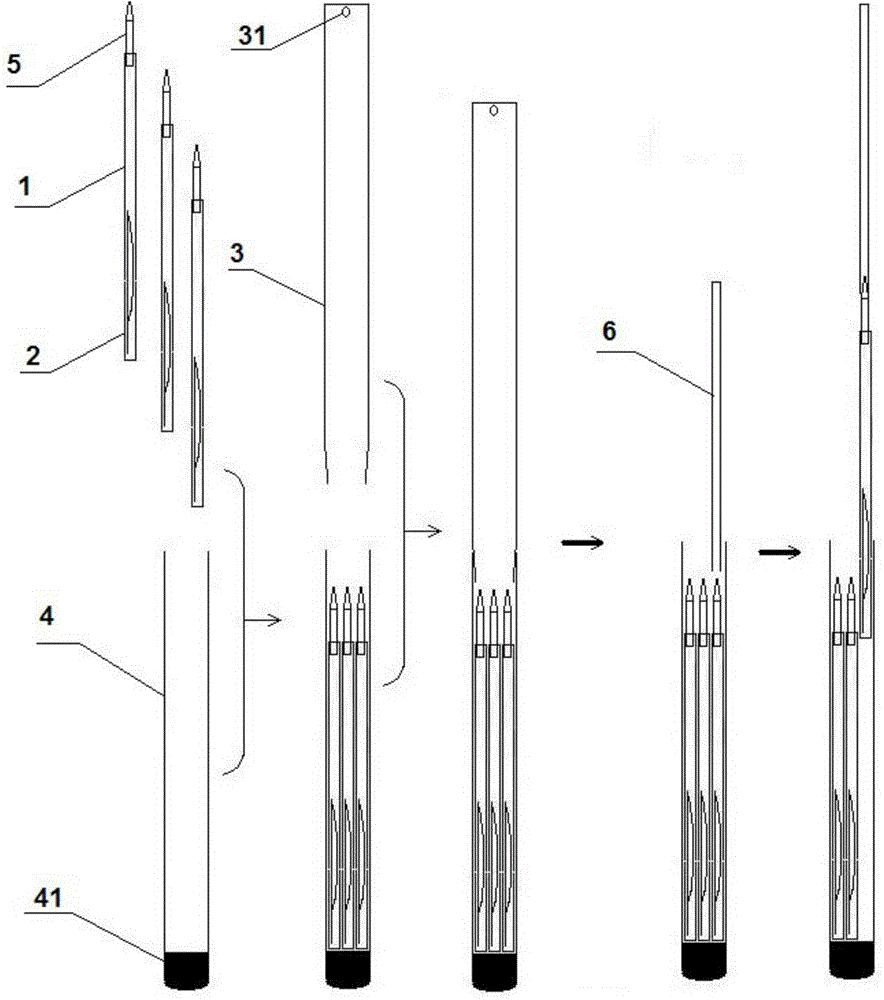

[0062] The vitrification carrier system provided in this embodiment includes a freezing rod 1, a freezing rod casing 2, an extension sleeve 3 and a protective tube 4.

[0063] The freezing rod 1 comprises a rod body, the rod body is composed of a lower extension part 11 and an upper handle part 12, and the lower end of the extension part 11 is connected with a cryopreservation sheet 13;

[0064] The freezing rod casing 2 is a hollow structure with a closed top, and an opening connecting the hollow structure with the external environment is provided at the upper end; Inside the hollow structure, a loading unit is formed.

[0065] The outer diameter of the extension 11 is smaller than the outer diameter of the handle 12 , and the distance between the outer surface of the extension 11 at the handle 12 and the outer surface of the handle 12 is equal to the wall thickness of the opening of the freezing rod sleeve 2 .

[0066] At least one or both of the outer surface of the extens...

Embodiment 3

[0072] The difference between this embodiment and Embodiment 2 is that: the protection cylinder 4 is provided with a transverse partition 42, which divides the protection cylinder into multiple sections, and each section forms a protection unit. The lower end is narrowed, inserted into the protective tube 4 from the top opening of the protective tube 4, and the side wall is provided with a window 43 that can put the loading unit in and out; the side wall of each other protection unit 402 is provided with a window 43.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com