Sorting production line

An assembly line and belt technology, applied in the field of sorting B07C items, can solve the problems of complex machinery and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

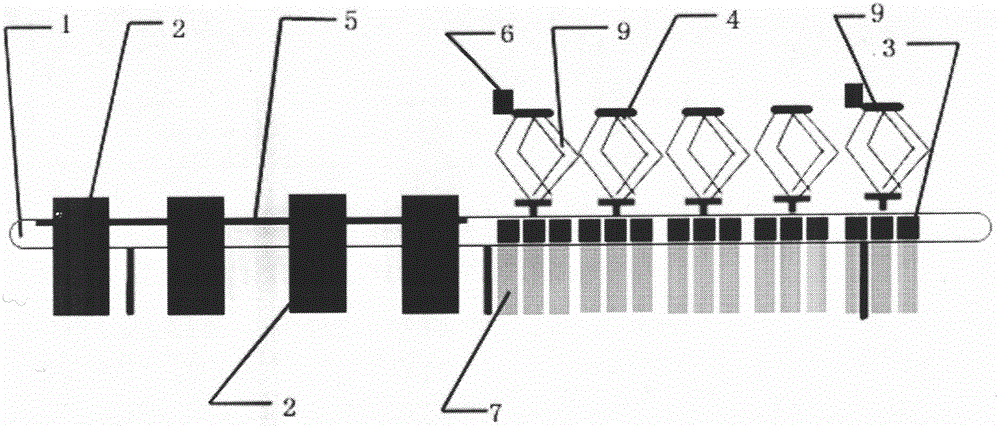

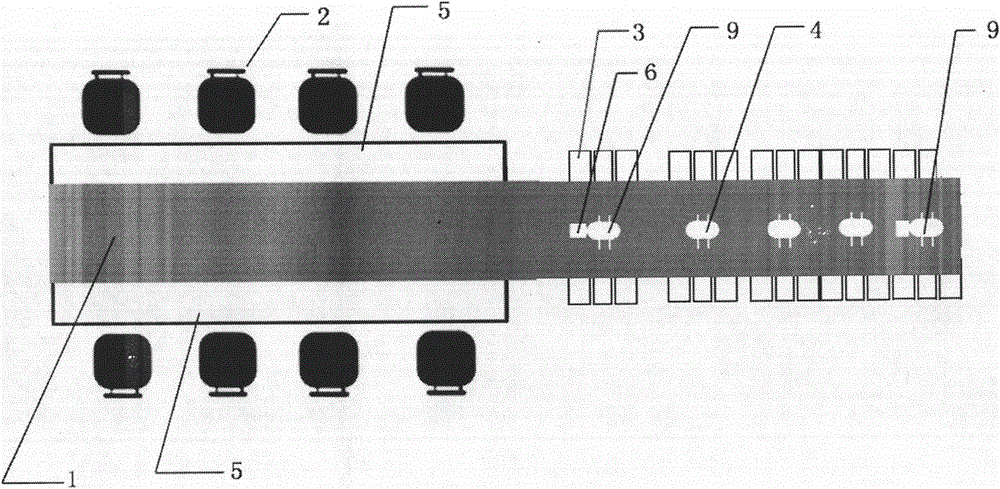

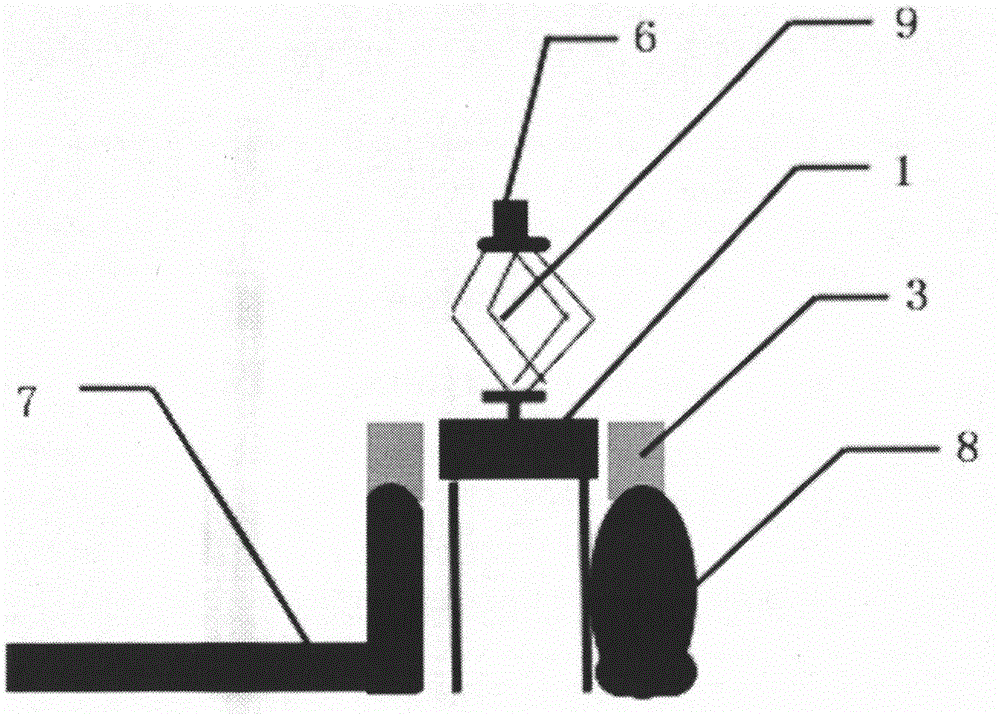

[0024] Embodiment 1 A vibrating screen is provided at the front end of the electric belt conveyor 1 to screen out large-sized garbage. A workbench 5 with a width greater than 0.3 meters is arranged on both sides of the electric belt conveyor 1 following the vibrating screen, and a seat 2 is arranged on the outside of the workbench 5 . Above the belt at the rear end of the electric belt conveyor 1, at least one spectral imager parallel manipulator 9 equipped with a spectral imager 6 is arranged, and a front-end spectral imager 6 can provide the integrated spectral imager parallel manipulator 9 with material composition, The position and speed information can also provide the information data of the material on the assembly line to one or more common cameras parallel manipulators 4 that are only equipped with ordinary cameras that can only capture the shape, color and orientation of the material at the back end but not equipped with a spectral imager. The spectral imager 6 at th...

Embodiment 2

[0025] Embodiment 2 Five spectral imager parallel manipulators 9 are arranged on the electric belt conveyor 1, and three feeding ports 3 are arranged on both sides of each parallel manipulator 4 of the parallel manipulators, and each feeding port 3 is connected to a material conveying pipeline 7. The material information data collected by the spectral imager 6 located at the end of the electric belt conveyor 1 is transmitted to the computer, and the computer transmits the speed-up or deceleration command to the governor of the electric belt conveyor 1 according to the quantity of selected materials that have not been detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com