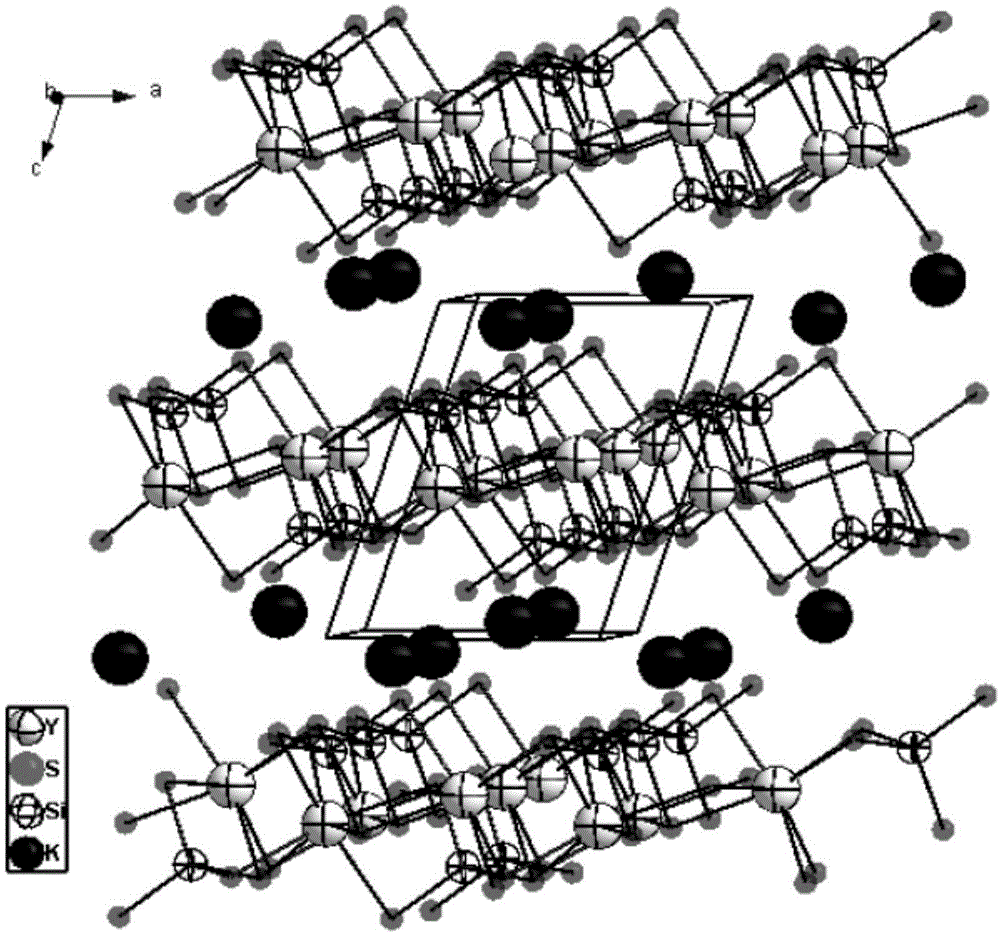

KYSiS4 compound, KYSiS4 nonlinear optical crystal, preparation method and application

A nonlinear optics and compound technology, applied in nonlinear optics, silicon compounds, chemical instruments and methods, etc., can solve the problems of slow development of nonlinear crystals, affecting practical use, difficult crystal growth, etc., achieving easy processing and preservation, The effect of fast growth and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of powdered KYSiS 4 Compound:

[0036]Using K 2 S+Y 2 S 3 +2SiS 2 =2KYSiS 4 The reaction formula is to prepare KYSiS by solid state reaction method 4 compound;

[0037] The K 2 S is 1.100 g, the Y 2 S 3 2.740 g, the SiS 2 is 1.840 grams; ie K 2 S:Y 2 S 3 :SiS 2 =0.01mol:0.01mol:0.02mol;

[0038] The specific operation steps are as follows: weigh the reagents in the glove box according to the above dosage, put them into the mortar, mix and grind them carefully, then put them into a Φ12mm×20mm quartz tube, and evacuate them to 10 -3 After pa, the quartz tube was melted and packaged with an oxyhydrogen flame, put into a muffle furnace, and slowly raised to 800°C, the heating rate was 50°C / hour, and the temperature was kept constant for 72 hours. After cooling, take it out. At this time, the sample is relatively loose. The sample is re-grinded and mixed, then placed in a quartz tube and vacuum-packed, and sintered in a muffle furnace at 800°C for...

Embodiment 2

[0040] Preparation of powdered KYSiS 4 Compound:

[0041] Using K 2 S+2Y+2Si+7S=2KYSiS 4 The reaction formula is to prepare KYSiS by solid state reaction method 4

[0042] compound; the K 2 S is 1.100 grams, the Y is 1.780 grams, the Si is 0.560 grams, and the S is 2.240 grams, namely K 2 S:Y:Si:S=0.01mol:0.02mol:0.02mol:0.07mol;

[0043] The specific operation steps are: weigh the reagents according to the above dosage in the glove box, put them into the mortar, mix and carefully grind them, then put them into a Φ12mm×20mm quartz tube, and vacuum to 10 -3 After pa, melt and package the quartz tube with a flame, put it into a muffle furnace, and slowly raise it to 900°C. The heating rate is 10°C / hour, and the temperature is constant for 72 hours. After cooling, take it out. At this time, the sample is relatively loose. Take out the sample again. Grind and mix well, then put it in a quartz tube and vacuumize it, and sinter it in a muffle furnace at 900°C for 72 hours. At...

Embodiment 3

[0045] Preparation of powdered KYSiS 4 Compound:

[0046] Using K 2 S+Y 2 S 3 +2Si+4S=2KYSiS 4 The reaction formula is to prepare KYSiS by solid state reaction method 4 compound; the K 2 S is 1.100 g, the Y 2 S 3 is 2.740 grams, the Si is 0.560 grams, and the S is 1.280 grams, namely K 2 S:Y 2 S 3 :Si:S=0.01mol:0.01mol:0.02mol:0.04mol;

[0047] The specific operation steps are as follows: weigh the reagents in the glove box according to the above dosages, put them into a mortar, mix and carefully grind them, then put them into a Φ12mm×20mm quartz tube, and evacuate them to 10 -3 After pa, melt and package the quartz tube with a flame, put it into a muffle furnace, and slowly raise it to 900°C. The heating rate is 30°C / hour, and the temperature is kept constant for 72 hours. After cooling, take it out. At this time, the sample is relatively loose. Grind and mix well, then put it in a quartz tube and vacuumize it, and sinter it in a muffle furnace at 900°C for 72 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com