Device and method for adjusting flame temperature of VAD and OVD on line

A technology of flame temperature and flame, which is applied in the field of quartz blowtorch, can solve the problems of destroying fluid mechanical properties, achieve the effects of reducing production costs, accurate and stable distribution of refractive index profile, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

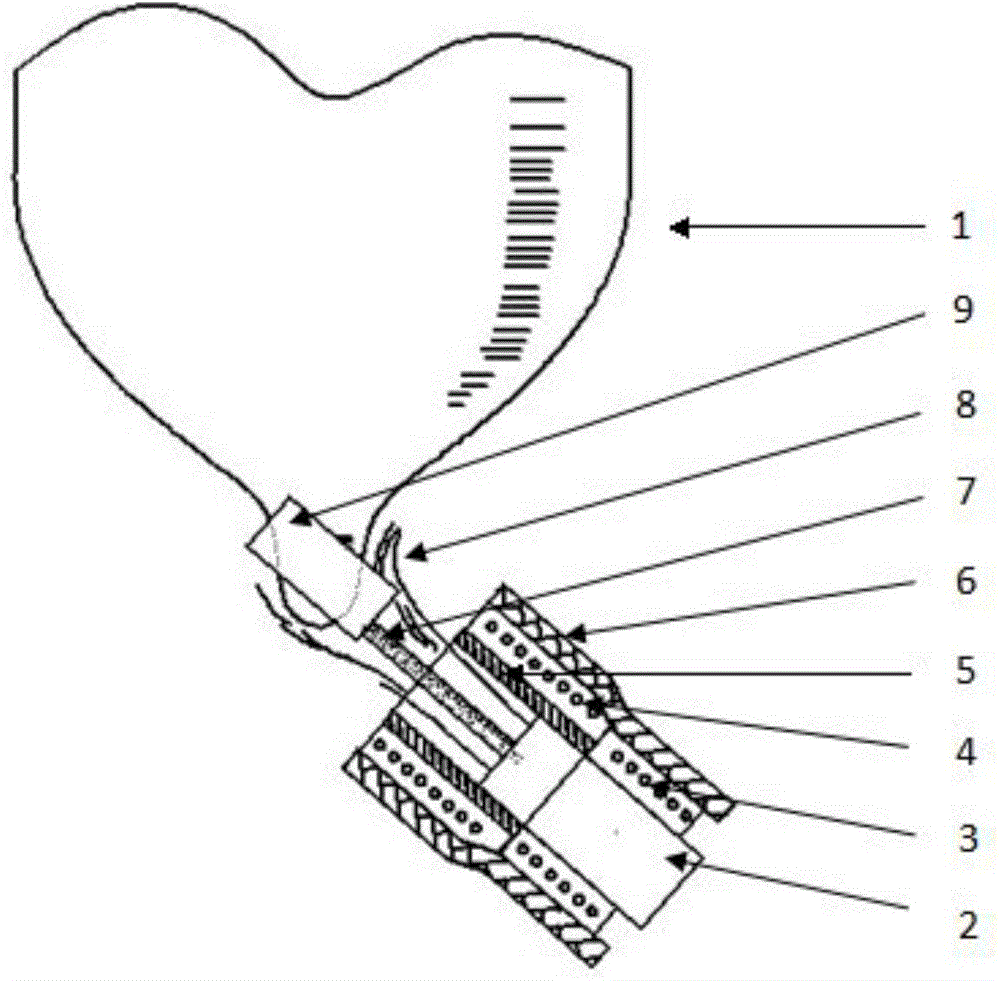

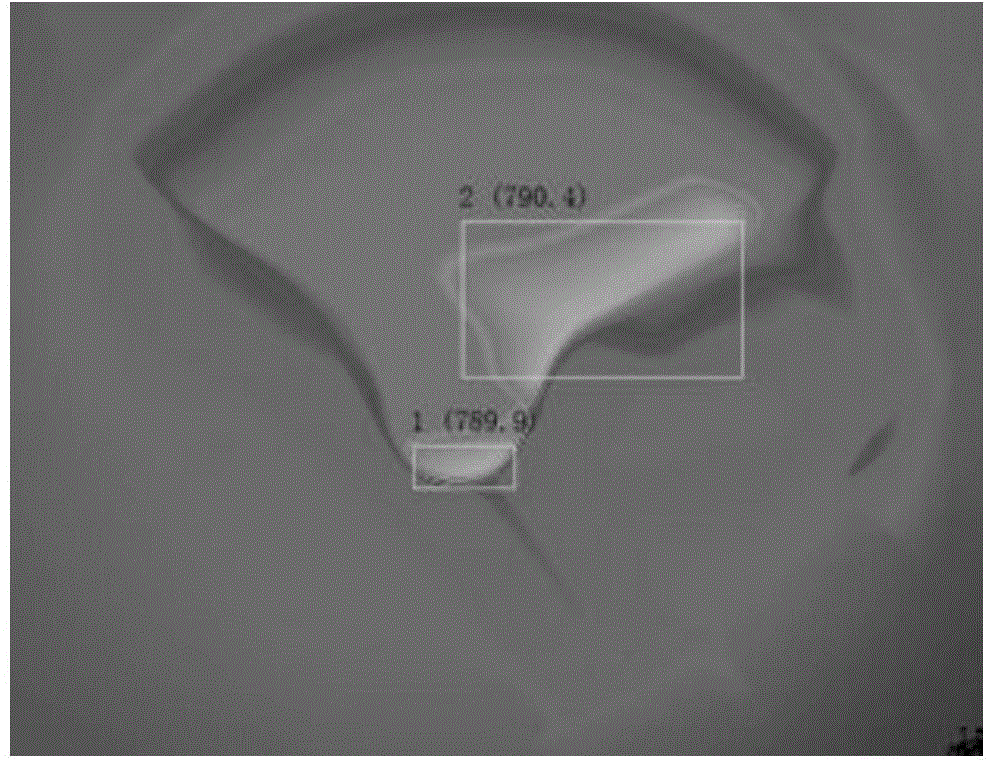

[0042] This embodiment discloses a device for online adjustment of the flame temperature of VAD and OVD, which adjusts the flow rate of each gas in each channel of the torch according to the geometric size of the quartz torch and the requirements of the deposition rate, so that the gas in each channel in the reaction flame And the generated dust particles meet the basic laminar flow mechanical properties. Generally speaking, this gas flow ratio will cause the heat generated by the combustion reaction to be lower than the heat energy required for actual deposition.

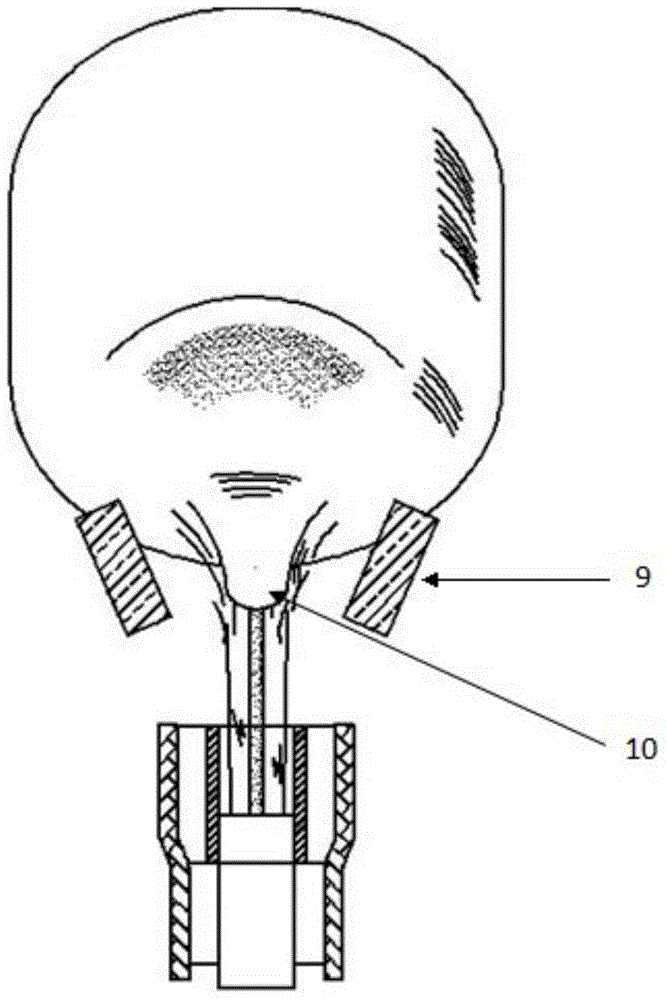

[0043] Such as Figure 1-2 As shown, the device includes a blowtorch 2 on the VAD core layer and a sleeve 5 arranged at the outlet of the blowtorch 2, and the blowtorch 2 is a quartz blowtorch, and the sleeve 5 is a quartz sleeve.

[0044] The aperture of the above-mentioned sleeve 5 is slightly larger than the outer diameter of the outlet of the above-mentioned torch 2 and can be clipped to the outlet of the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com