Method for improving binding force of priming paint on aluminum alloy parts

A technology of aluminum alloy parts and bonding force, which is applied in the direction of metal material coating process, etc., can solve the problems of uneven film layer, affecting production progress, paint falling off, etc., achieves the effect of simple technical operation and improved surface protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

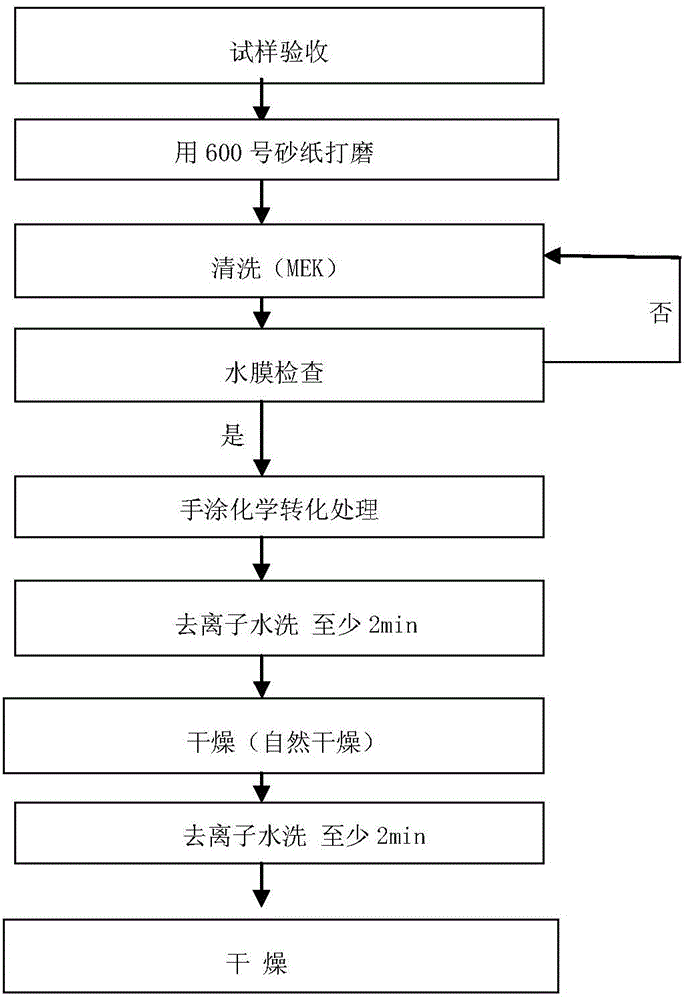

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

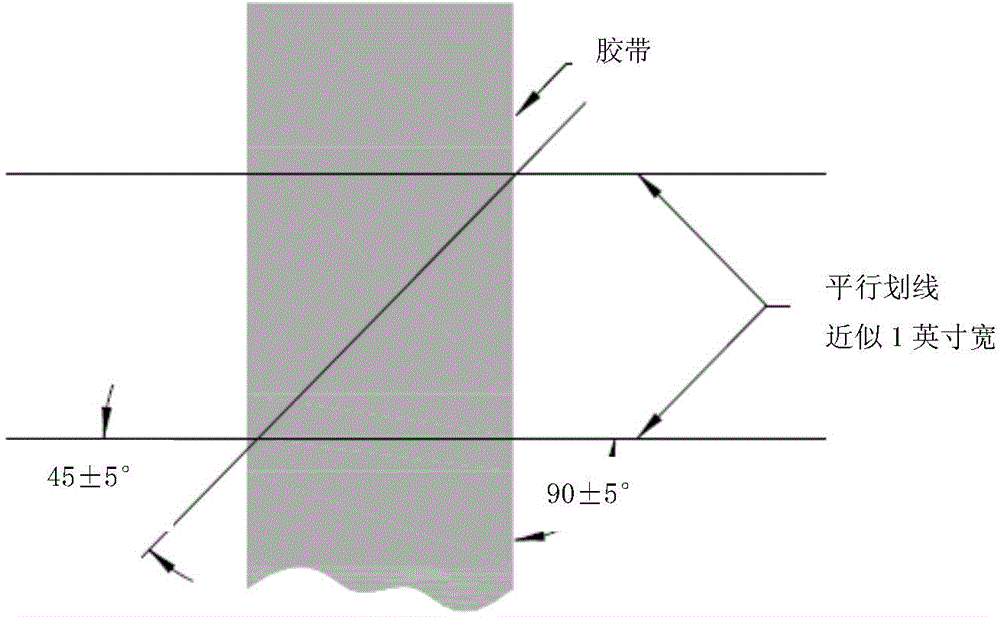

[0025] The method for improving the bonding force of the primer of the aluminum alloy part is to increase the surface of the machined part without affecting the tolerance of the part. layer, which disrupts the texture of the surface of the part and improves the roughness of the substrate surface, so that it is easy to form a film on the aluminum alloy substrate during the chemical conversion treatment. The appearance of the film layer is continuous and complete, which effectively improves the bonding force of the part paint .

[0026] Next, choose the material of 7010T7451 as the sample. The roughness of the sample is Ra1.6μm, and the verification test is carried out to measure the performance of the hand-coated chemical conversion film (appearance, powdery film, dry and wet bonding force after painting, etc.) , to determine the feasibility of the process pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com