Full-automatic washing machine based on PLC control

A fully automatic washing machine and motor technology, which is applied in the control device, washing device, textile and paper making of washing machine, etc., can solve the problems of easy damage, high energy consumption and noise generation of the washing machine, and achieve easy transformation, reduce external wiring, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

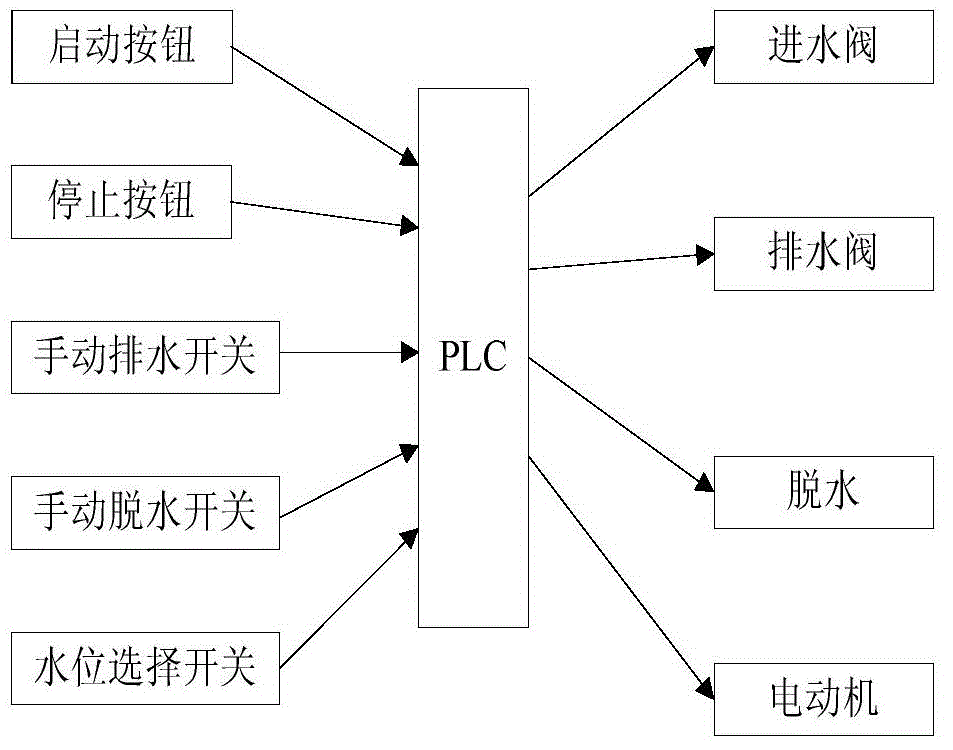

[0019] A fully automatic washing machine based on PLC control mainly includes a relay group, a programmable controller and a frequency converter. Among them, the relay group is connected with the programmable controller, and the programmable controller is connected with the frequency converter. The relay is the main executive module, and its opening and closing directly control the circuit, realizing the control of the motor.

[0020] The above-mentioned PLC sends digital commands to control the coil work of the relay.

[0021] As the core of the control, the above-mentioned PLC samples various external input signals.

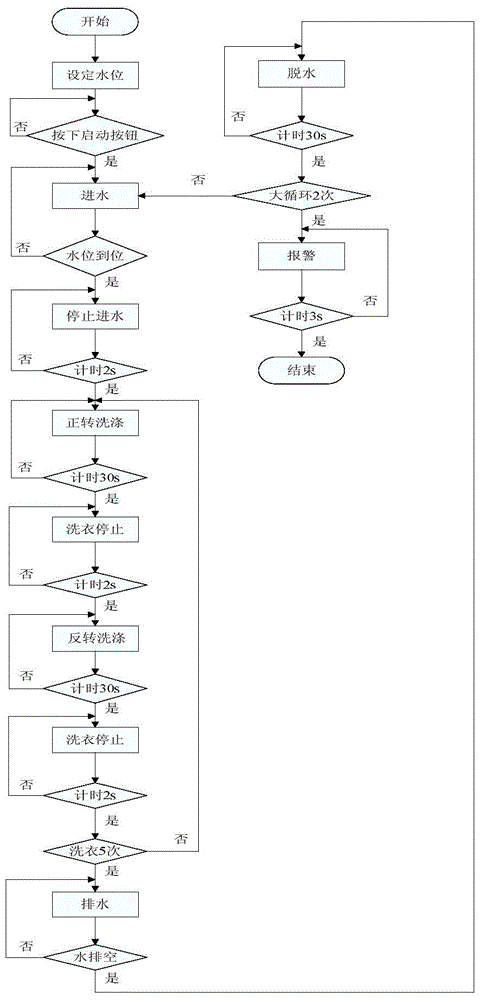

[0022] The above-mentioned PLC uses a timer to record the time of the motor's forward rotation, reverse rotation, drainage, dehydration and alarm, and uses a counter to record the times of the motor's forward rotation, reverse rotation, drainage, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com