Method for treating soft soil foundation through deep compound vacuum pre-compaction

A vacuum preloading method and soft soil foundation technology, which is applied in the fields of soil protection, infrastructure engineering, construction, etc., can solve the problems of contact phenomenon, shrinkage and deformation of pressurized filter tubes, and small rigidity of pressurized filter tubes, etc., to achieve good reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

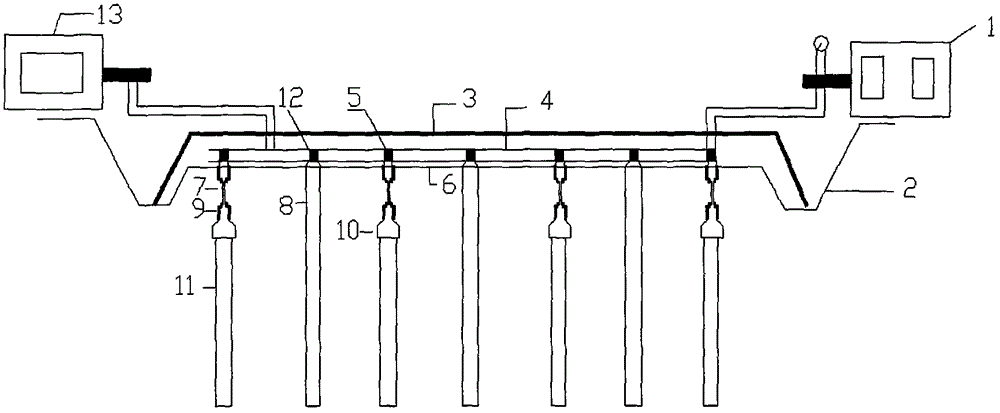

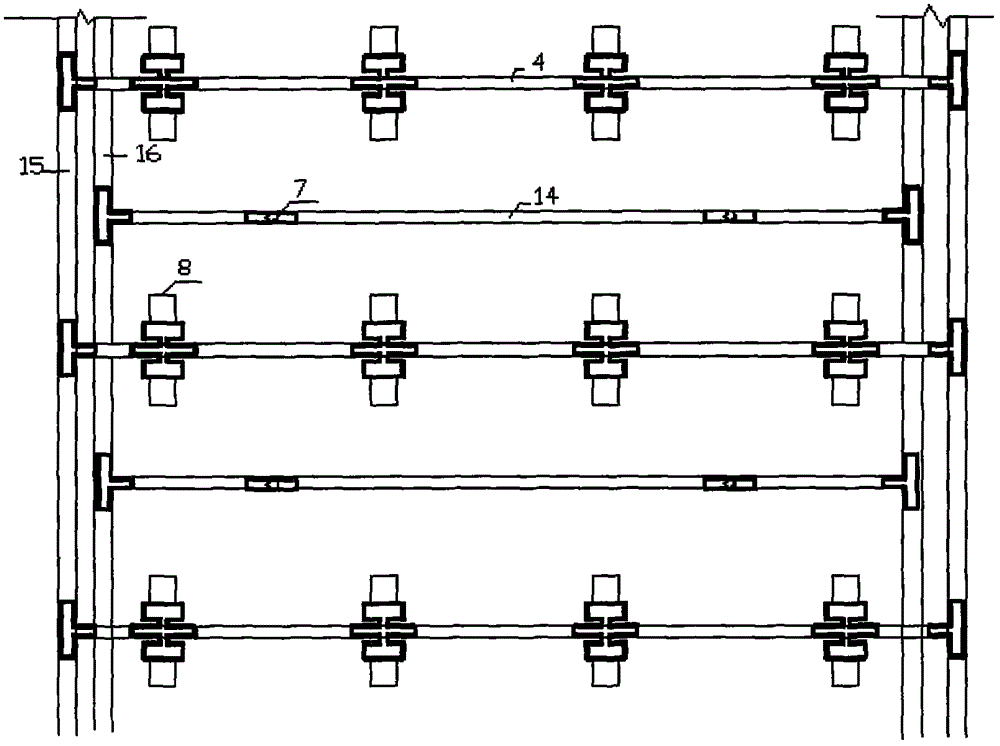

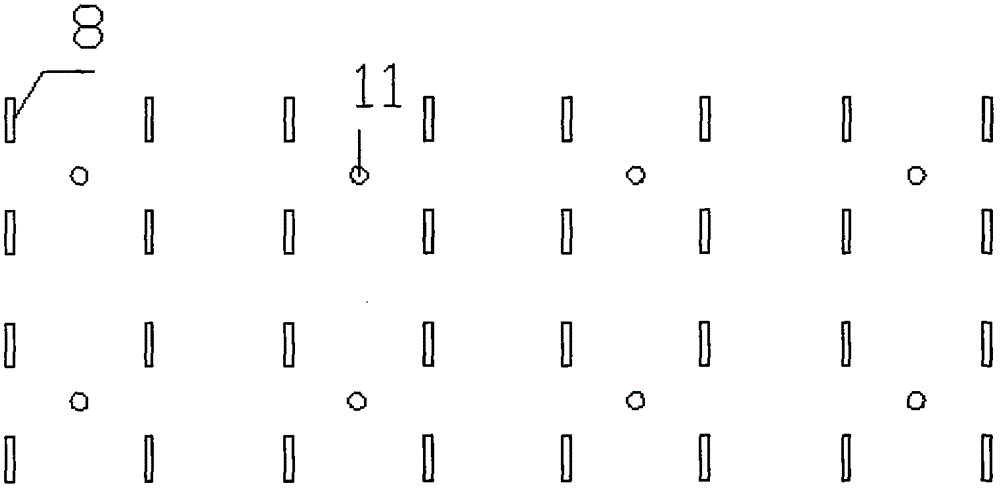

[0020] During specific implementation, a layer of woven cloth 6 is laid on the soft ground that needs to be treated, the plastic drainage board 8 in the vacuum system and the plastic drainage board 11 in the booster system are positioned, and the vertical drain board 11 in the booster system is positioned. The drainage board 11 is connected to the vertical pressurized air pipe 7, and then the plastic drainage board in the vacuum system and the plastic drainage board in the pressurization system are set respectively afterwards, and the plastic drainage board 8 in the vacuum system is passed through the hand type. The joint 10 is connected with the horizontal drainage branch pipe 4, the plastic drainage plate in the pressurized system is connected with the vertical gas transmission pipe 7 and the special double-way conversion joint 9 with the horizontal gas transmission branch pipe 14, and the horizontal drainage branch pipe 4 is connected to the horizontal drainage main pipe 15....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com