Concrete temperature preservation brick

A technology of thermal insulation bricks and concrete, which is applied in the direction of building materials, etc., can solve the problems of poor compressive strength, multiple raw materials, and lack of thermal insulation effects, etc., and achieve the effects of reasonable structural design, guaranteed thermal insulation performance, and saving raw materials for production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

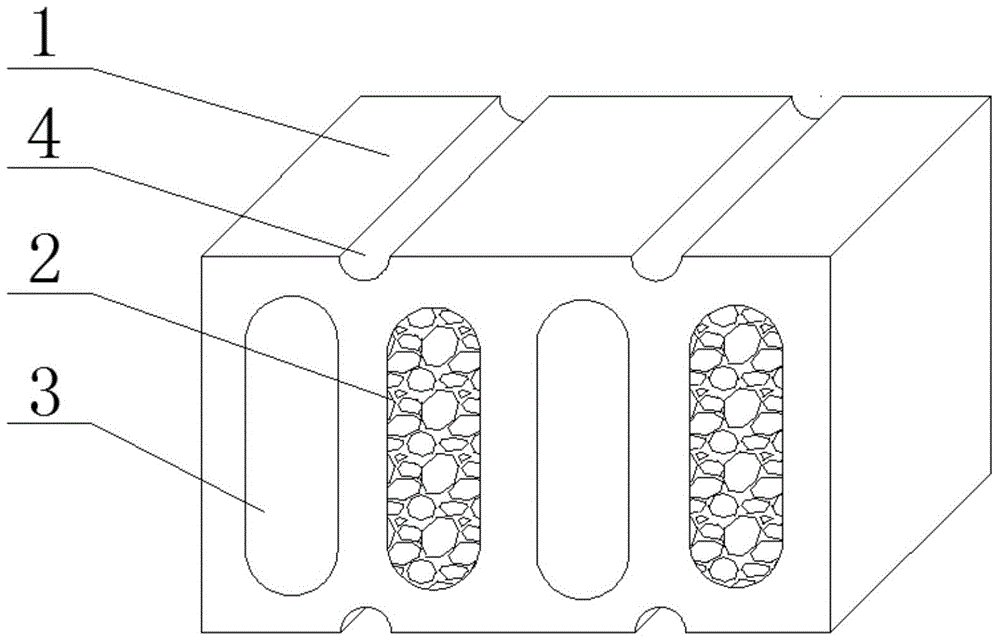

[0015] Such as figure 1 As shown, a concrete insulation brick includes a brick body 1, and the brick body 1 is provided with two filling holes 2 and two through holes 3, and the filling holes 2 are filled with polystyrene foam insulation materials to achieve For the purpose of heat preservation, the filling holes 2 and the through holes 3 are alternately arranged at intervals, and two semicircular grooves 4 are respectively provided on both sides of the long side of the brick body 1 . The size of the brick body 1 is a standard size of 390mm╳190mm╳190mm. In this embodiment, the filling hole 2 has a length of 135 mm and a width of 50 mm, and the through hole 3 has a length of 125 mm and a width of 50 mm. The semicircular groove 4 is located at a distance of 85mm from both sides of the brick body 1, and the radius of the semicircular groove 4 is 15mm.

[0016] In this embodiment, the design of the through hole 3 and the semicircular groove 4 saves raw materials for production; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com