Coiling type one-step corrosion preventing and heat preserving operating line of steel pipeline

A steel pipe, winding technology, applied in the field of steel pipe anti-corrosion heat preservation treatment process and equipment, can solve the problems of anti-corrosion pipe operation line can not heat preservation, heat preservation pipe anti-corrosion function is poor, service life extension, etc., to overcome the poor anti-corrosion function, The effect of shortening the production cycle and extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

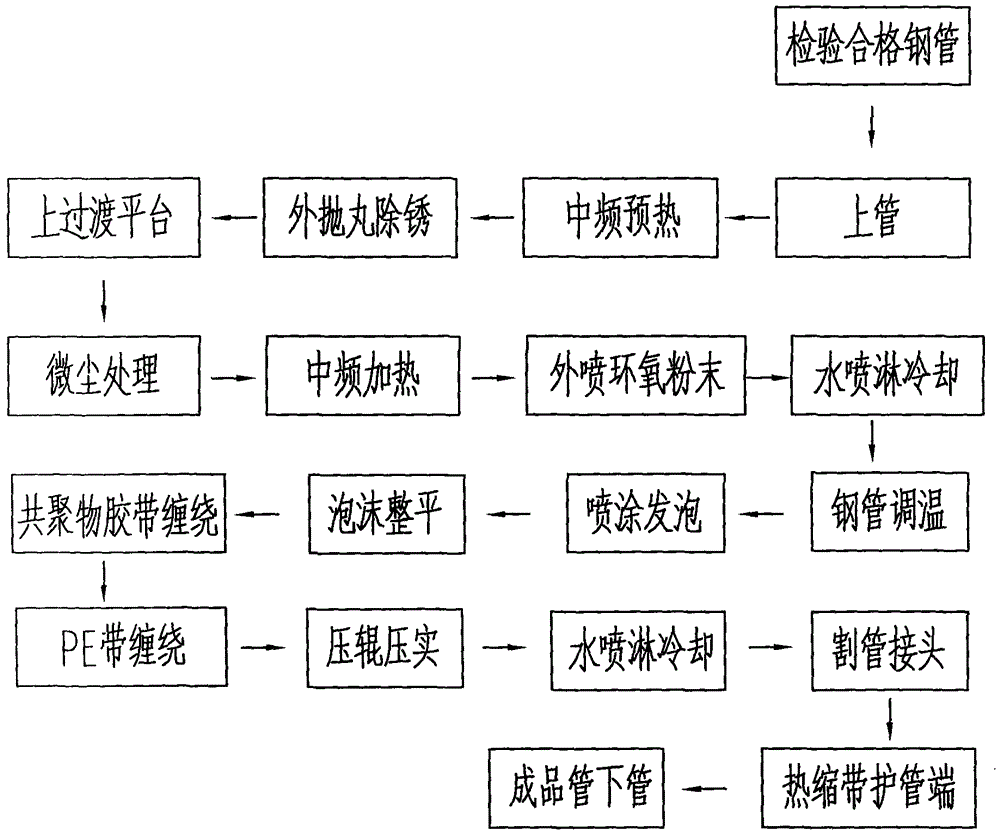

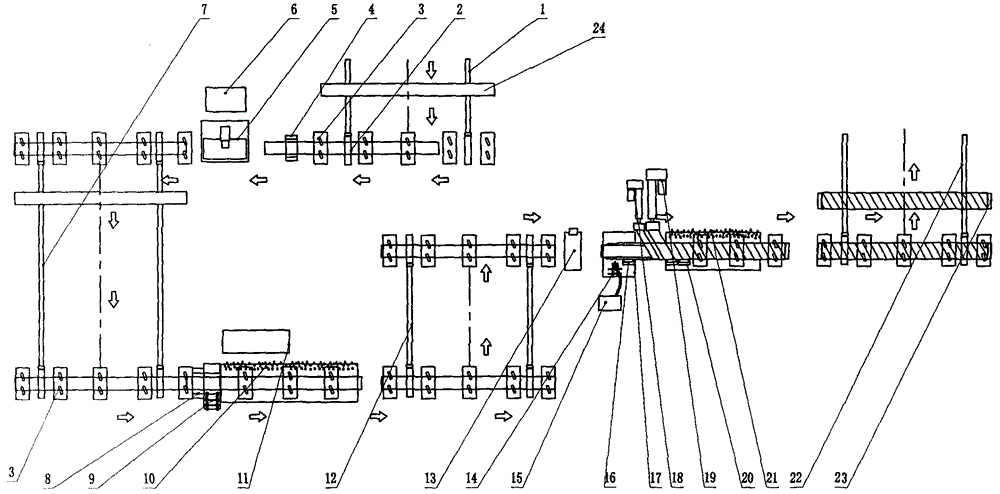

[0041] Such as figure 2 As shown, a steel pipe winding type "one-step method" anti-corrosion and heat preservation operation line of the present invention includes an upper pipe platform 1, a pipe pulling mechanism 2, a conveyor 3, an intermediate frequency preheating system A4, and an external shot blasting derusting machine 5, Dust removal system 6, intermediate frequency heating system B8, epoxy powder spraying system 9, water spray cooling system 10, steel pipe temperature adjustment device 13, spray foaming equipment 15, copolymer tape extruder 18, PE tape extruder 19, The lower pipe platform 22 and the steel pipes to be processed 24 are arranged in order by the pipe shifting mechanism 2 to straighten the steel pipes 24 to be processed on the upper pipe platform 1, and then placed on the upper pipe platform 2 by the conveyor 3 The steel pipelines 24 to be processed are pushed forward sequentially. The intermediate frequency preheating system A4 is located between the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com