Process for increasing temperature of tail gas of biomass hot combustion gas

A technology of biomass and hot gas, applied in the direction of biofuel, improvement of process efficiency, burner, etc., can solve the problems of not meeting the temperature requirements and low calorific value of biomass, so as to avoid thermal pollution, environmental protection and energy saving Requirements, Effects of Reducing Dependency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

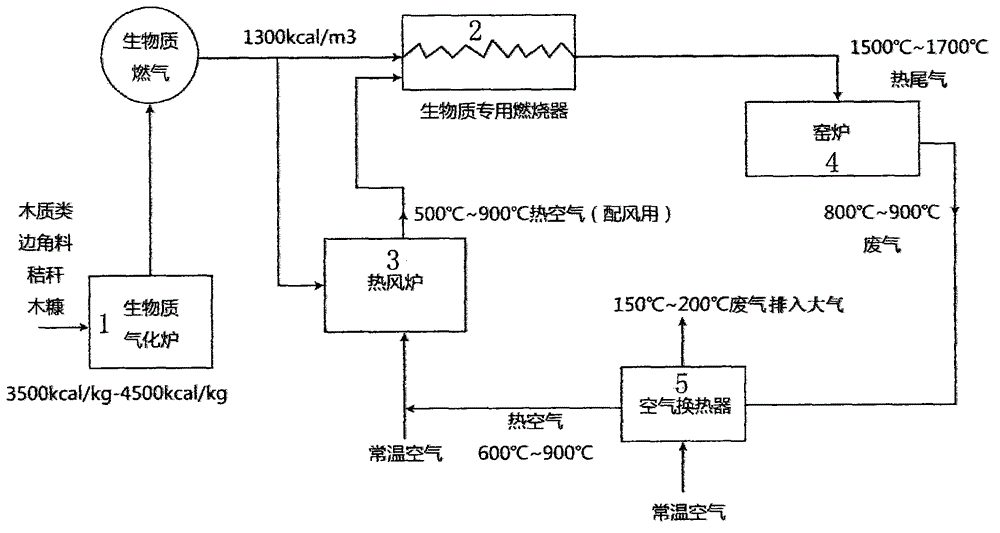

[0013] Below in conjunction with accompanying drawing, the patent of the present invention is further described.

[0014] In the figure, the patent of the present invention is mainly composed of equipment such as biochemical furnace 1, combustion furnace 2, hot blast furnace 3, kiln 4 and air heat exchanger 5.

[0015] Patent of the present invention comprises the following steps to implement successively:

[0016] a. The biomass fuel is sent into the biomass gasifier 1, and the biomass is wood scraps, straw and wood bran, etc.

[0017] b. The gasification furnace 1 pyrolyzes and gasifies the clean hot gas and enters the special biomass burner 2 .

[0018] c. The hot blast stove 3 uses part of the hot gas to exchange heat with the air at normal temperature to form hot air at 500°C-900°C, which is used as combustion air for the burner.

[0019] d. After the biomass hot gas and the hot air sent by the hot blast stove 3 are co-combusted in the burner 2, the flame temperature af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com