A method for preventing blast holes from collapsing and realizing smooth charging

A technology of blasting and collapsing holes, applied in blasting and other directions, can solve the problems of high blasting cost and easy blockage of blasting holes, and achieve the effects of ensuring blasting effect, avoiding dust pollution and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The method provided by the present invention to prevent blast hole collapse and realize smooth charging comprises the following steps:

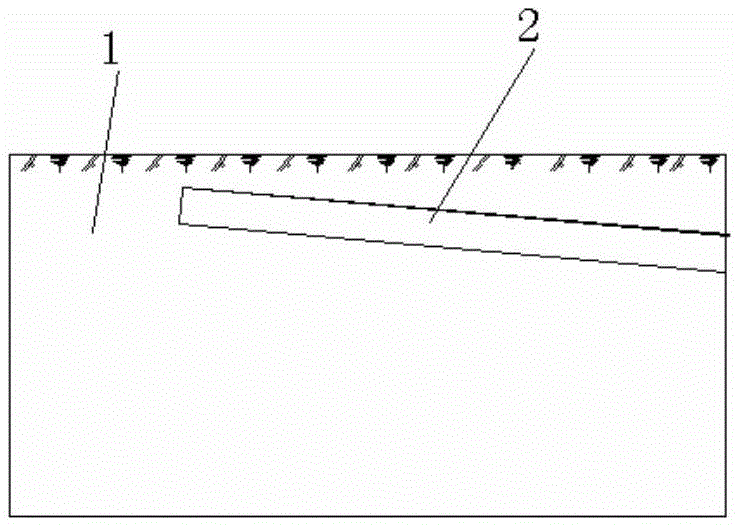

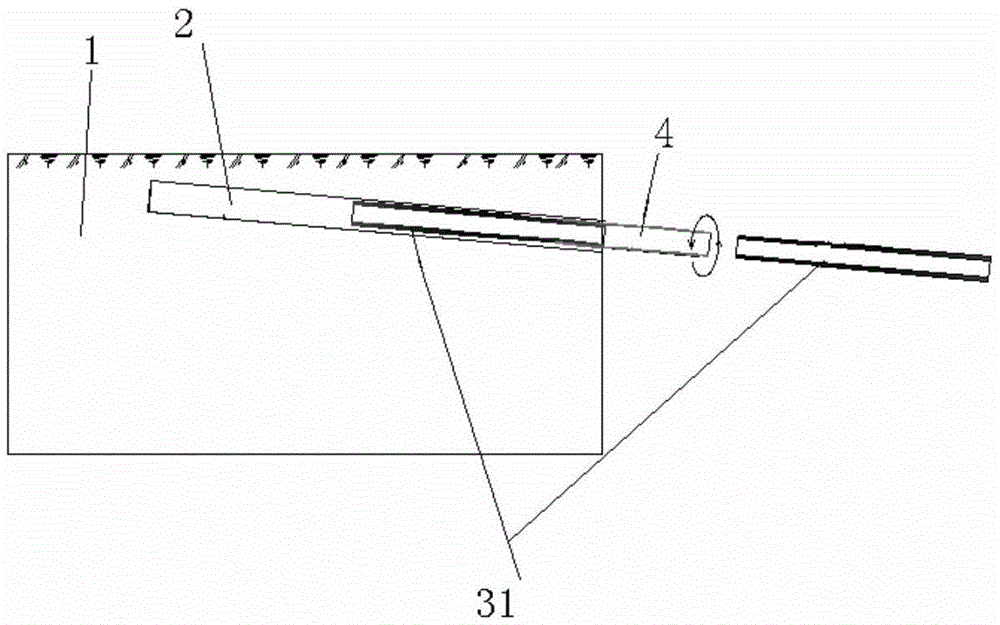

[0038] S1, such as figure 1 and figure 2 As shown, after the blast hole 2 is drilled on the rock mass 1, the sleeve 3 is filled in the blast hole 2 immediately; Root short sleeve 31 is long 1-2m, and short sleeve 31 external diameters are slightly smaller than blast hole 2 internal diameters, and short sleeve 31 internal diameters are slightly larger than the charge roll diameter of packing or slightly larger than the required internal diameter of blasting charge; The barrel 3 is made of a material with a certain strength and toughness, so as to adapt to a small amount of deflection of the blast hole 2 caused by construction accuracy.

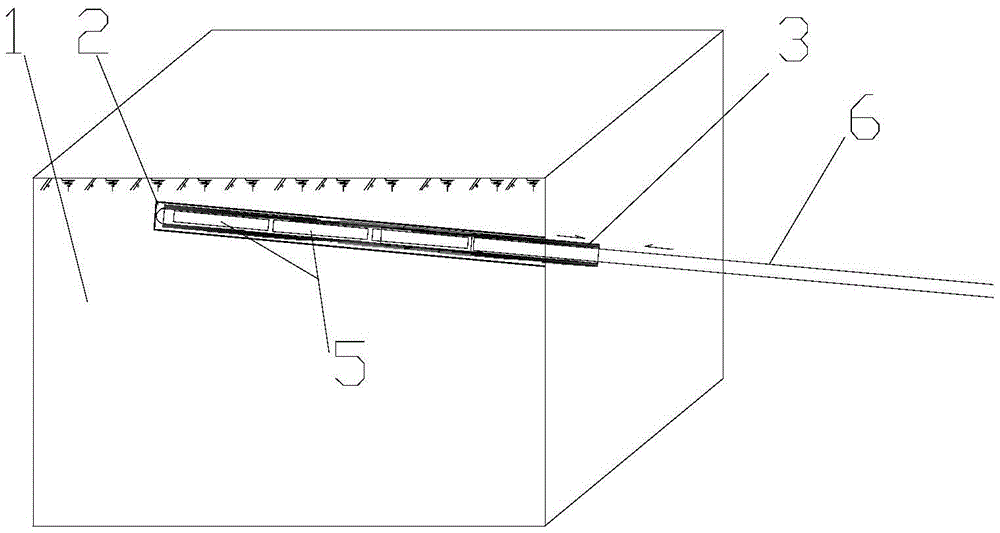

[0039] S2. Load the explosive volume 5 into the sleeve 3; of course, the explosives in the blasting package can also be in other forms.

[0040] S3, such as image 3 As shown, insert the barrel rod...

Embodiment 2

[0052] On the basis of Embodiment 1, Embodiment 2 specifically takes the blasting mining of a mine in my country as an example to introduce the method of the present invention for preventing blast holes from collapsing and realizing smooth charging.

[0053] In this mine, due to the deep burial of the ore body, the large in-situ stress, the large change in the hardness of the upper and lower walls of the ore rock, the development of joints and fissures in the ore body, the ore body is relatively broken, and the quality of rock drilling is poor. There is a time interval between them, and the blasthole 2 of the first construction has collapsed when the blasthole 2 is all drilled and begins to charge. In order to reduce the impact of collapsed holes and shorten the time for drilling blast holes 2 and charging as much as possible, in the past, mines used blast holes 2 with an average footage of 2m and a diameter of blast holes 2 of 42mm. The blasting time is 6-8 hours. Due to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com