Monitoring system for magnetic leakage detection equipment

A technology of equipment monitoring and magnetic flux leakage detection, which is applied in the direction of signal transmission system, electrical signal transmission system, material magnetic variable, etc., can solve the problems of time-consuming and labor-intensive, affecting the process of industrial transportation, etc., to achieve large measurement range, stable temperature performance, The effect of meeting real-time requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

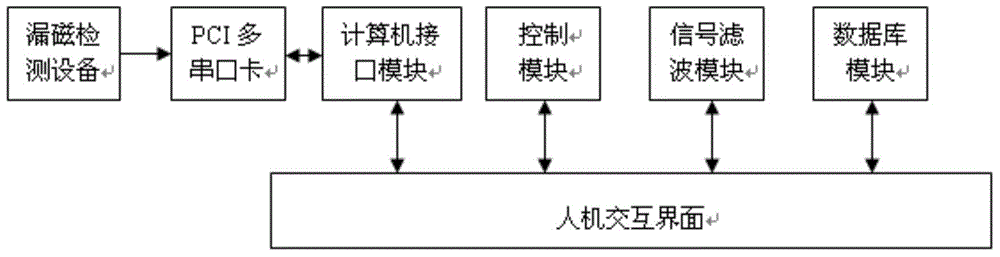

[0016] A monitoring system for magnetic flux leakage detection equipment, which consists of a computer interface module, a signal filtering module, a database module, an automatic detection control module, and a human-computer interaction interface.

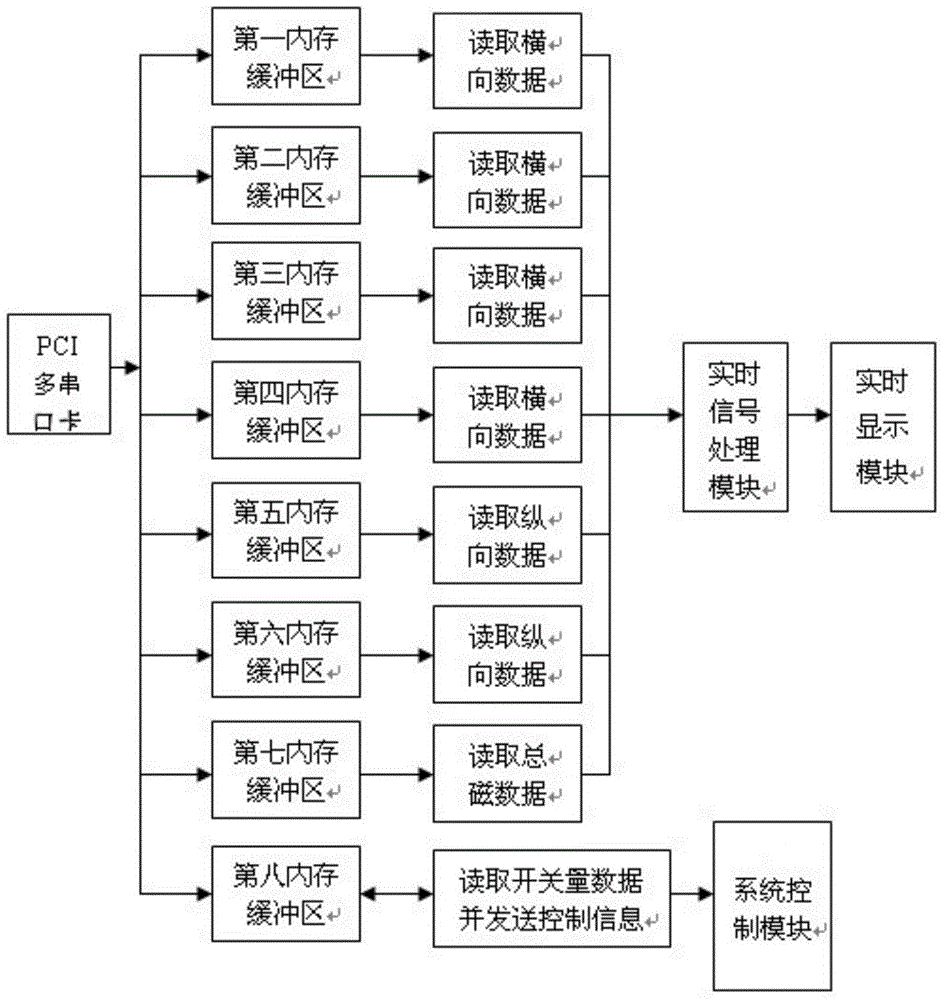

[0017] It is characterized in that the computer interface module is connected to receive the incoming data from the PCI multi-serial port card in the hardware part.

[0018] It is characterized in that the signal filter module is used to remove noise to obtain the magnetic flux leakage signal we need.

[0019] to combine figure 1 , figure 1 Design the scheme structure for the monitoring system of magnetic flux leakage detection equipment. The magnetic flux leakage detection method is used to detect the leakage magnetic field. The condition of the paint layer on the outside of the pipeline will not affect the detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com