Filtering mechanism of filter and non-clogging high-precision sewage filter

A filter mechanism and filter technology, applied in the direction of filter separation, filter circuit, chemical instruments and methods, etc., can solve the problems of insufficient cleaning force, loss of filter function, large sediment content, etc., to achieve protection from wear and tear, Long service life and guaranteed filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

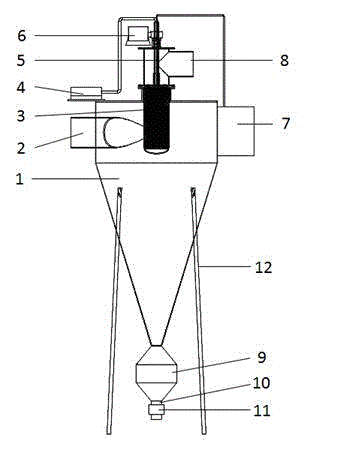

[0044] see figure 1 , the invention discloses a non-clogging high-precision sewage filter. As shown in the figure: it includes a filter mechanism, which is set in a cyclone body 1 with an inlet pipe 2. The lower end of the cyclone body 1 has a sewage reservoir 9 and a sewage discharge valve controlled by a solenoid valve 11. Pipe 10; the metal sintered mesh 3 of the filtering mechanism has an outlet pipe 8. The cyclone body 1 is conical, and the cyclone body 1 is connected and supported by a bracket 12 .

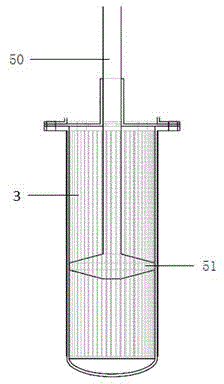

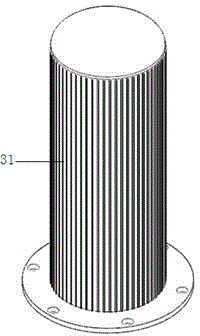

[0045] Please combine figure 1 refer to Figure 2-7 , the filtering mechanism of the filter includes a metal sintered mesh 3, a cleaner 5, a high-pressure water supply device 4 and a transmission mechanism 6; wherein: one end of the metal sintered mesh 3 is sealed, and the other end is welded with a standard flange; the cleaner 5 includes The transmission rod 50 and the pressure plate 51 connected to one end of the transmission rod 50, the pressure plate 51 is arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com