Intensive pre-treatment equipment for city and town restaurant-kitchen wastes

A technology for kitchen waste and pretreatment, applied in the direction of solid waste removal, etc., can solve the problem of no urban kitchen waste classification collection, transportation and treatment device, etc., to achieve reduction and comprehensive utilization, and reduce investment costs. , the effect of simplifying the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

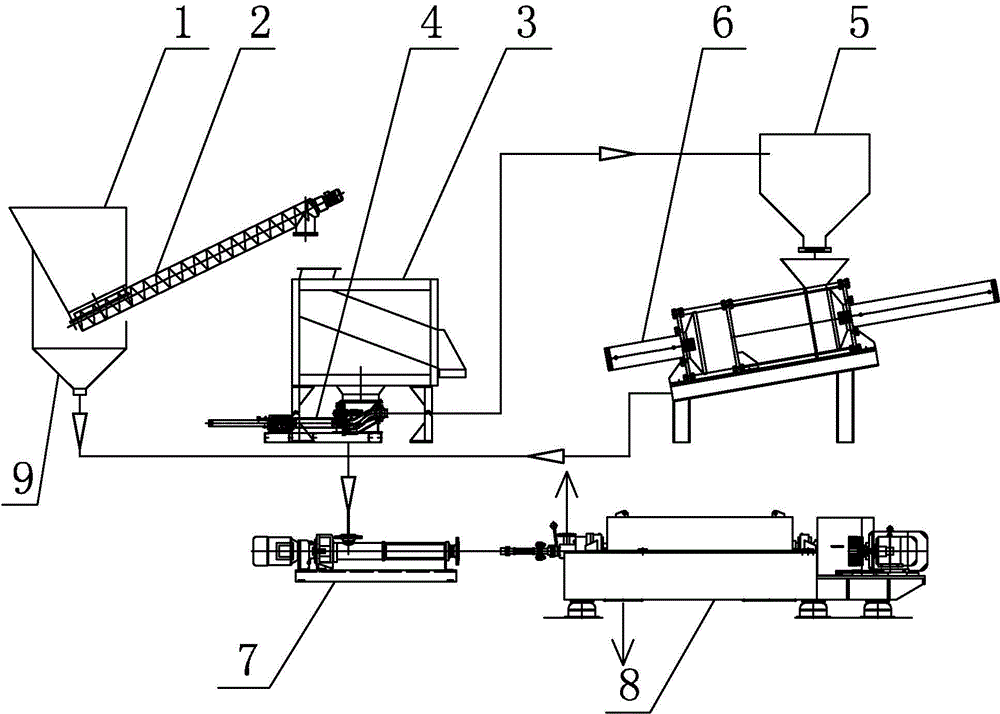

[0012] Specific implementation manner one: such as figure 1 As shown, the urban kitchen waste intensive pretreatment equipment of this embodiment includes a hopper 1, a drain screw conveyor 2, a sorter 3, a piston pump 4, a buffer silo 5, a press 6, and a leachate transfer pump 7. The three-phase separator 8 and the filtrate collection hopper 9, the lower end of the collection hopper 1 and the inlet of the drain screw conveyor 2 are connected with each other. The drain screw conveyor 2 is arranged at an inclined angle, and the inlet of the drain screw conveyor 2 is lower than The discharge port of the drain screw conveyor 2 has a drain hole at the bottom of the inlet end of the drain screw conveyor 2, and the diameter of the drain hole is 4-6mm. A filtrate collection bucket 9 is arranged below the inlet end of the drain screw conveyor 2, and the drain The discharge port of the screw conveyor 2 is located directly opposite to the upper inlet of the sorter 3. The lower end of the...

specific Embodiment approach 2

[0015] Specific implementation manner two: such as figure 1 As shown, the drain screw conveyor 2 in this embodiment is a dual-frequency drain screw conveyor. With such a design, the conveying capacity can be adjusted according to the load of the downstream equipment, and at the same time, it can be reversed to prevent the drain screw conveyor 2 from being blocked. The other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation manner three: such as figure 1 As shown, the hole diameter of the drain hole in this embodiment is 5 mm. It is convenient for the water to flow out from the drain hole, and the materials to be placed flow out from the drain hole. Other components and connection relationships are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com