Cutting machine with double oblique draw bars

A technology of oblique pull rod and cutting machine, which is applied in the direction of metal sawing equipment, metal processing machinery parts, maintenance and safety accessories, etc. Many problems, such as the large area occupied by the inner pressure plate and the outer pressure plate, achieve the effect of light weight, stable tension and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

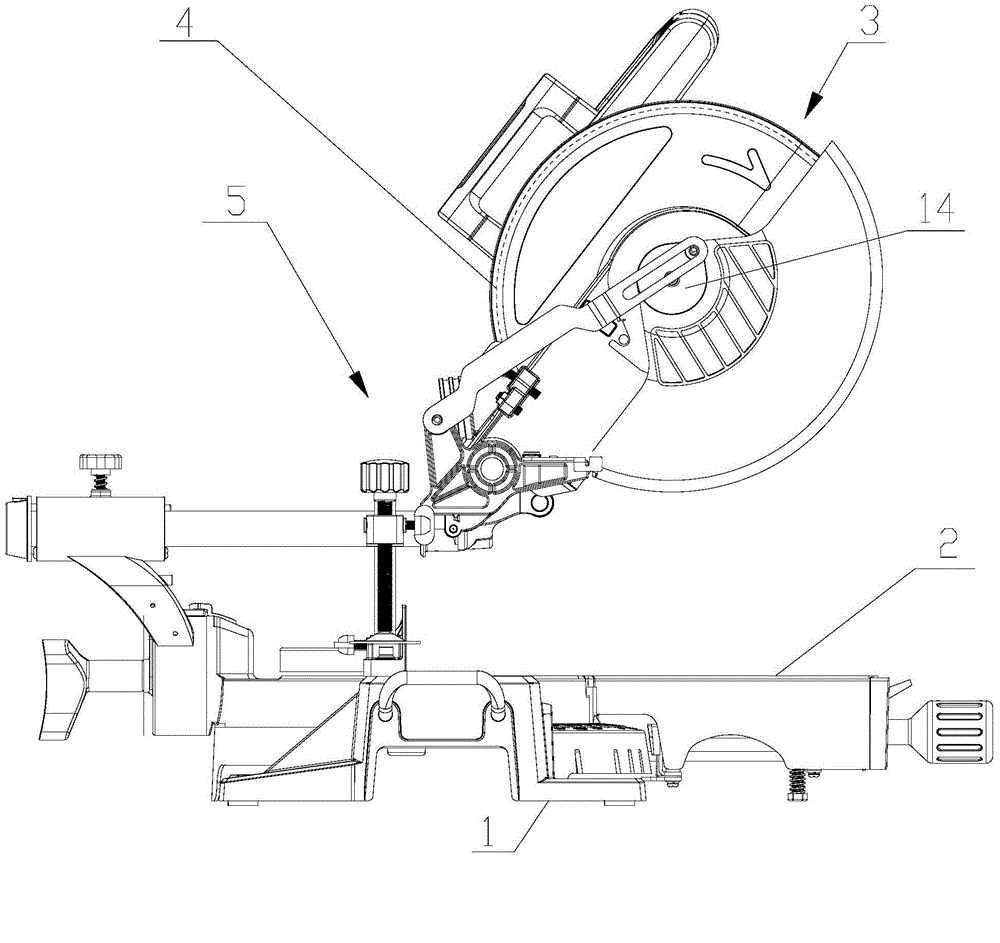

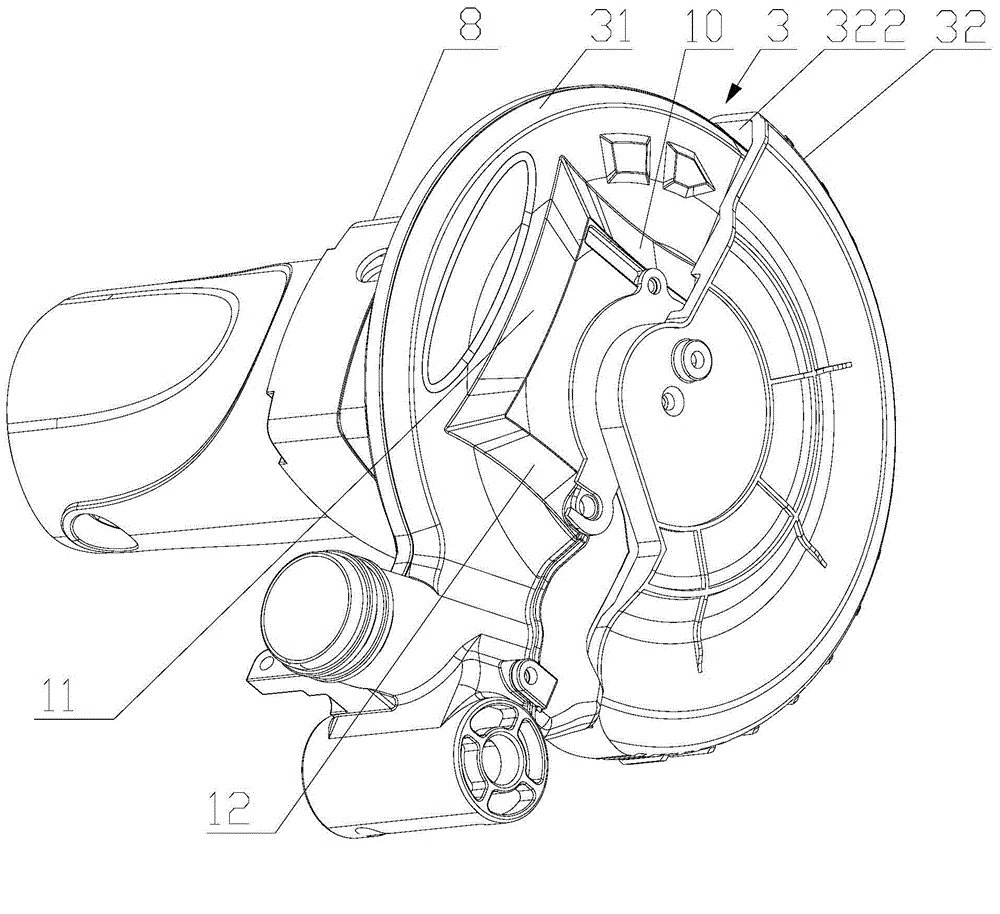

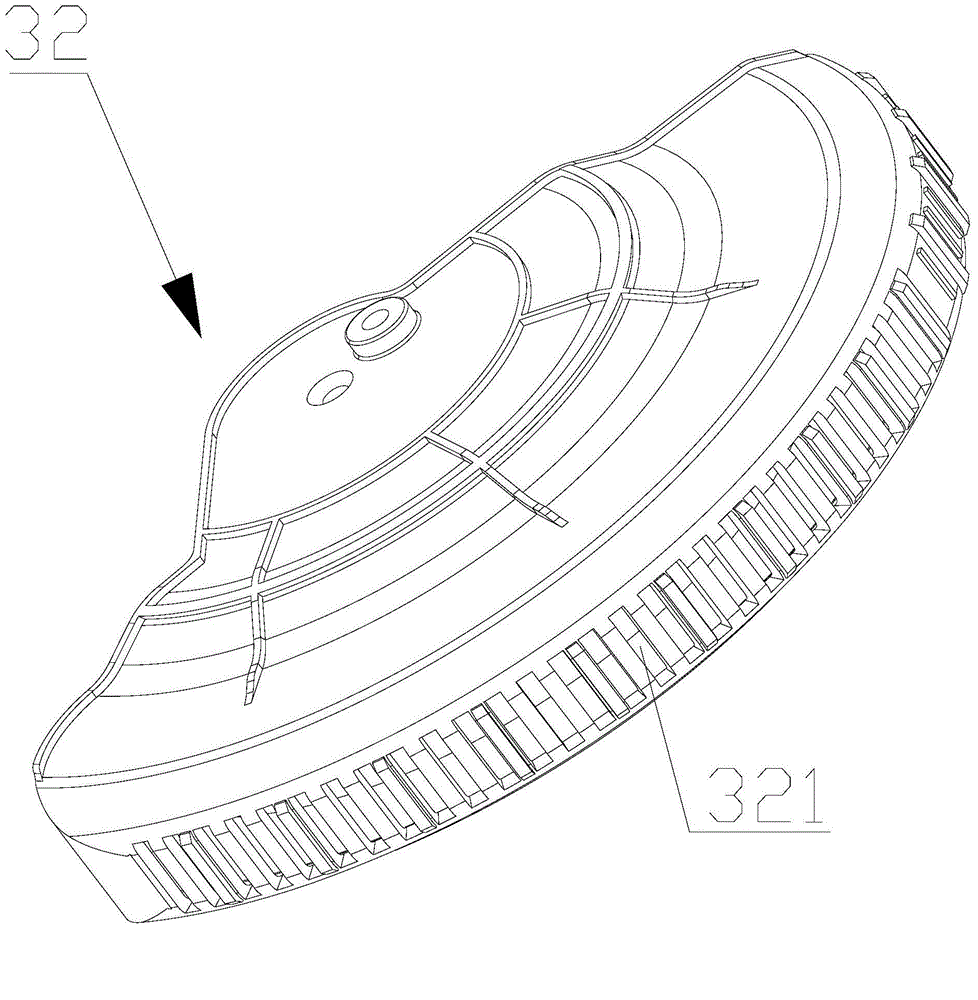

[0047] A kind of double oblique rod type cutting machine, such as Figure 1-18 As shown, including a base 1, a workbench 2, a rotating mechanism 5, and a saw blade 4, the workbench 2 and the rotating mechanism 5 are all arranged on the base 1, the saw blade 4 is supported on the rotating mechanism 5, and the saw blade 4 is provided with Protection device 3, saw blade 4 both sides are provided with positioning clamping device, and protection device 3 comprises fixed protective cover 31 and the movable protective cover 32 that is hinged outside fixed protective cover 31, and positioning clamping device comprises inner pressure plate 6 and is arranged inside. The outer pressure plate 7 on the pressure plate 6, the saw blade 4 is sandwiched between the inner pressure plate 6 and the outer pressure plate 7, the saw blade 4 is connected with a driving device through a pulley transmission, the driving device includes a gear box 8, and the pulley transmission includes a belt 9, Belt 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com