Consumable electrode gas shielded-welding welding line identification visual sensor

A technology of MIG and vision sensor, applied in the field of welding seam recognition visual sensor, can solve the problems of MIG welding spatter and smoke, poor image, missed field of view, etc., to avoid the tracking speed being too slow and reducing Adverse effects, good reachability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

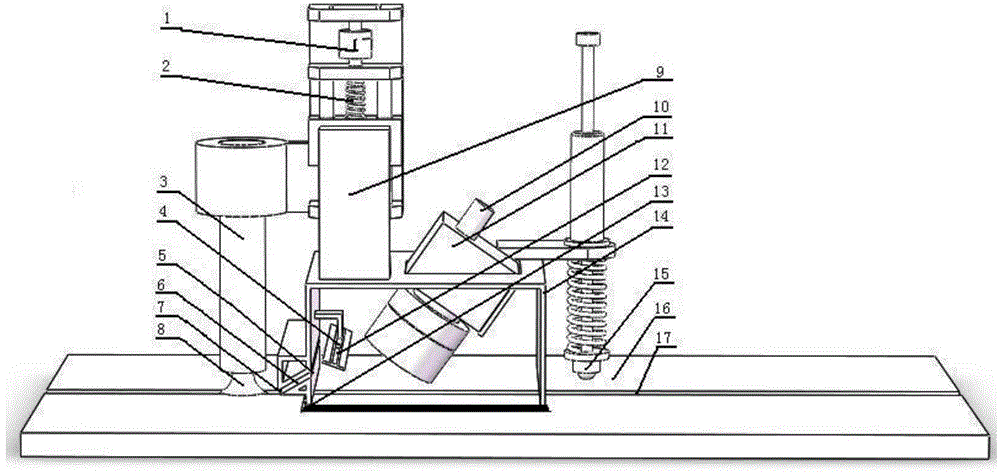

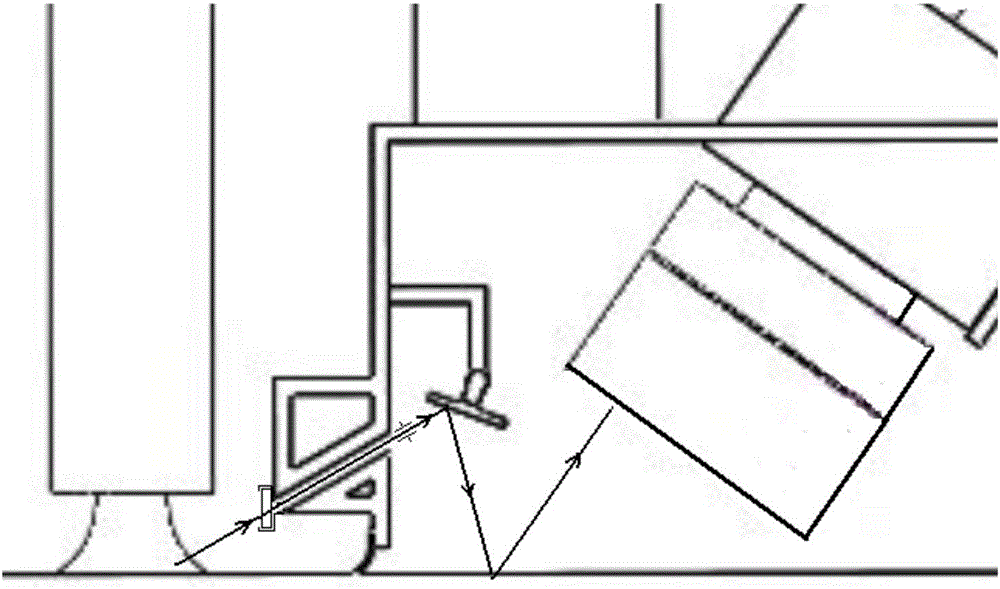

[0023] Such as figure 1 and image 3 As shown, it is a structural diagram and an optical path diagram of a visual sensor for gas metal shielded welding seam recognition, the sensor is fixed on the welding torch 3, including: an arc light transmission system, an image acquisition system and a constant value control system for the relative height of the light shield; described

[0024] The arc light transmission system includes: diaphragm 5, light guide plate 6, flat glass 7, light-transfer mirror 12 and flame-retardant sponge 13;

[0025] The image acquisition system is composed of an industrial camera 11 with an Ethernet output interface 10;

[0026] The relative height constant value control system of the light-blocking cover is composed of a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com