Energy-saving and reliable AC electric welding machine

A technology of alternating current and alternating current power, used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high energy consumption, unreliable performance of electric welding machines, complex structure, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

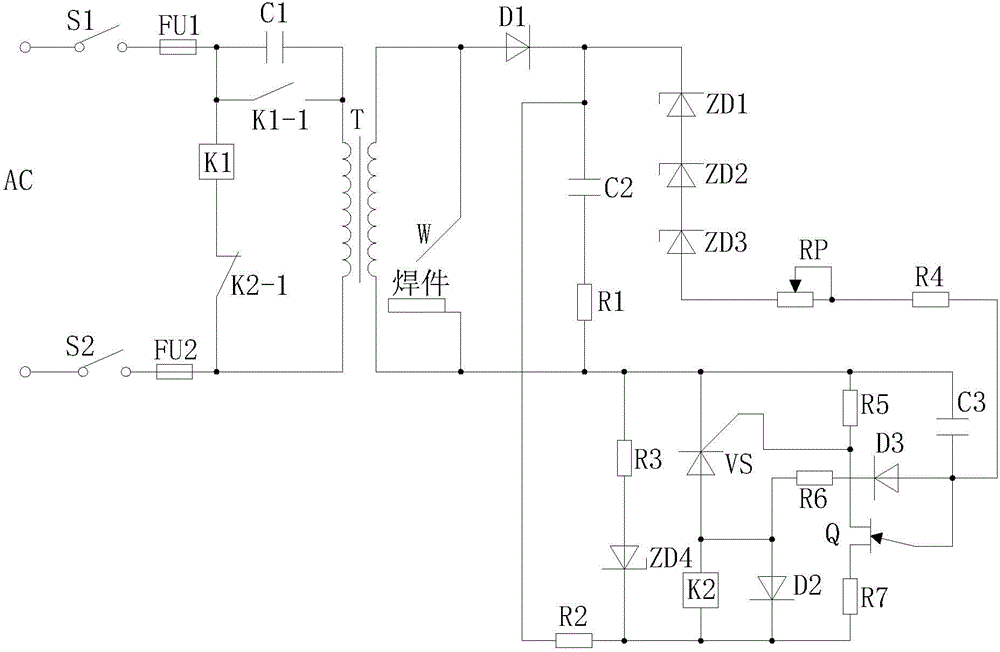

[0009] The present invention will be further described below in conjunction with accompanying drawing:

[0010] like figure 1 As shown, the present invention is an energy-saving and reliable AC welding machine, including AC power supply AC, first switch S1, second switch S2, first fuse FU1, second fuse FU2, first relay K1, second relay K2 , the first capacitor C1 to the third capacitor C3, the normally open contact switch K1-1 of the first relay, the normally closed contact switch K2-1 of the second relay, the transformer T, the welding handle W, the first diode D1 To the third diode D3, the first resistor R1 to the seventh resistor R7, the first zener diode ZD1 to the fourth zener diode ZD4, the potentiometer RP, the one-way thyristor VS and the unijunction transistor Q, the AC power supply AC The first end is connected to the first end of the first switch S1, the second end of the AC power supply AC is connected to the first end of the second switch S2, the second end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com