Large-scale double-curve-surface structure manufacturing multipurpose tooling

A hyperboloid, multi-purpose technology, applied in the direction of manufacturing tools, workpiece clamping devices, auxiliary devices, etc., can solve problems such as increased cost and workload, unfavorable deformation control, and out-of-tolerance contours, so as to reduce workload and stick The effect of large joint surface and improvement of manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

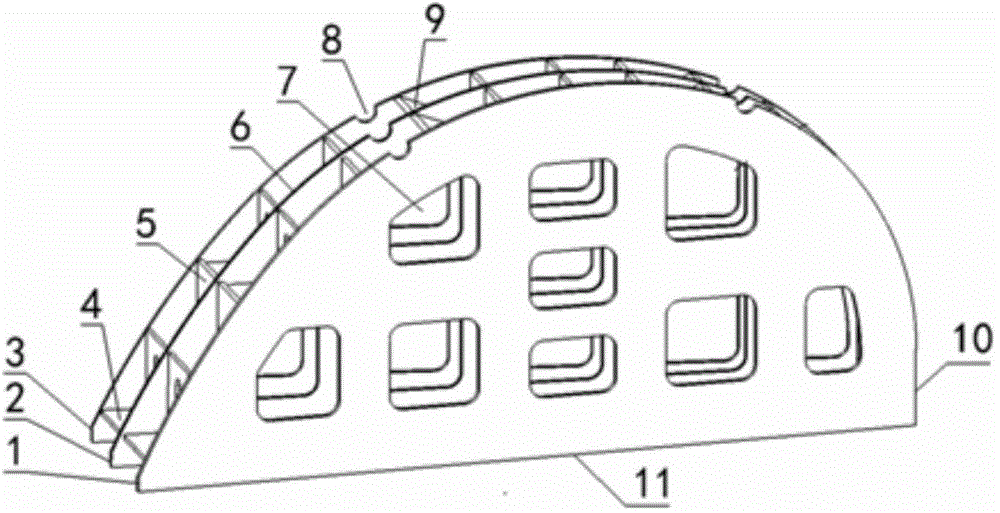

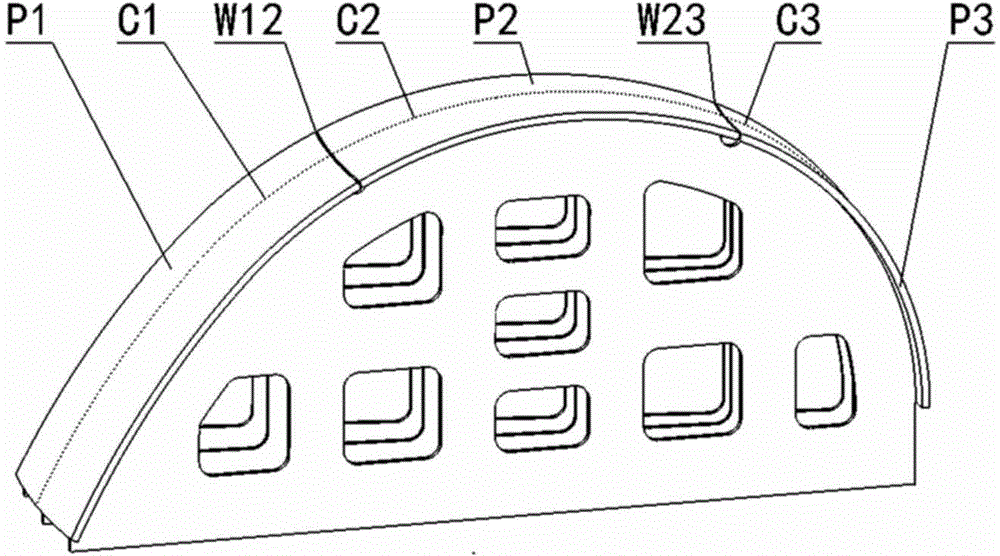

[0016] like figure 1 As shown, the large-scale hyperboloid structure manufacturing multi-purpose tooling includes a main structural plate, and the main structural plate includes a left main structural plate 3, a middle main structural plate 2, a right main structural plate 1, and a left main structural plate arranged side by side. The plate 3 and the main structural plate 1 on the right are respectively welded to the middle main structural plate 2 through several transverse ribs 4, vertical ribs 5, and oblique ribs 9. Arc-shaped, one side is provided with a vertical end plane 10, the vertical end plane 10 and the bottom plane 11 are perpendicular to each other, and each main structural plate 1, 2, 3 is provided with a semicircular gap on both sides of the upper arc-shaped surface 8. Several lightening holes 7 are distributed on each main structural plate 1, 2, and 3, and mid-plane scoring lines 6 are engraved on the contour surface of the middle main structural plate 2 except ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com