Surrounding type control mechanism for cooling system

A cooling system control and motion mechanism technology, applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems that affect the flexibility of the tool and easily cause interference, etc., and achieve simple structure, strong universality, and cooling good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

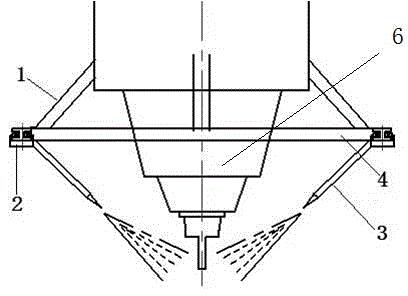

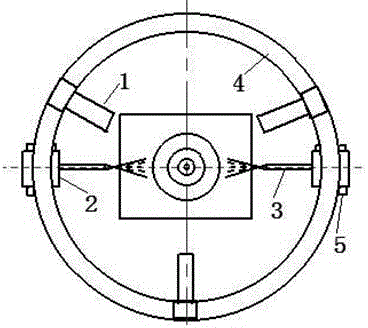

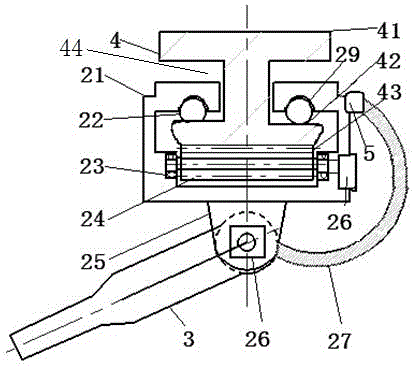

[0016] A surrounding cooling system control mechanism, including a circular guide rail 4, a moving mechanism 2 and a spray head 3, the front view is as follows figure 1 As shown, the top view is as figure 2 shown. The ring guide rail 4 is fixed on the machine tool through the bracket 1 (three brackets 1 are evenly distributed on the ring guide rail 4), and the center of the ring guide rail is concentric with the spindle of the CNC machine tool 6. The nozzle 3 is connected to the motion mechanism 2, and the motion mechanism 2 can be in the ring Moving on the guide rail 4, the nozzle 3 is connected to the "3-position 4-way electromagnetic reversing valve" 5 and rotates up and down around the movement mechanism 2. Therefore, the spray head 3 can rotate 360° around the cutter in the circumferential direction, and the direction can be adjusted up and down according to the length of the cutter, so as to realize omni-directional spraying without dead angle.

[0017] The ring guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com