Preparation method and application of photo-thermal material Fe3O4/polydopamine/polyisopropyl acrylamide

A technology of propylacrylamide and polydopamine, which is applied in the field of photothermal material preparation, can solve the problems such as the difficulty of remote operation of liquid droplets, and achieve the effects of convenient acquisition of raw materials, wide application prospects, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

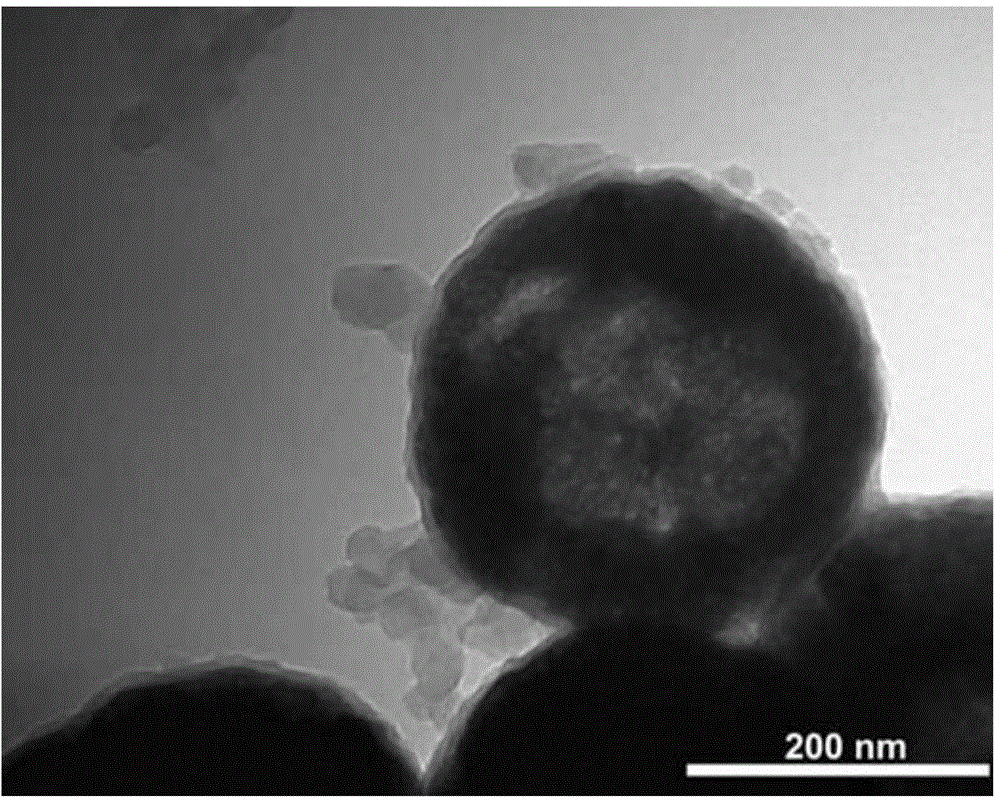

[0019] Specific implementation mode 1: This implementation mode is a kind of photothermal material Fe 3 o 4 The preparation method of / polydopamine / polyisopropylacrylamide is specifically carried out in the following steps:

[0020] 1. Preparation of Fe 3 o 4 Dispersion solution: Fe 3 o 4 Nanoparticles are ultrasonically 10min~60min in the aqueous solution of trishydroxymethylaminomethane to obtain a dispersed solution; the mass ratio of trishydroxymethylaminomethane in the aqueous solution of tris to deionized water is 1g:( 0.083L~4.13L); said Fe 3 o 4 The volume ratio of the mass of nanoparticles to tris aqueous solution is 1g:(2L~100L);

[0021] 2. Preparation of Fe 3 o 4 / Polydopamine nanoparticles: Add dopamine to the dispersion solution obtained in step 1, and stir for 10h to 36h at a stirring speed of 100r / min to 900r / min to obtain Fe 3 o 4 / Polydopamine nanoparticle dispersion, the Fe 3 o 4 / Polydopamine nanoparticles were sucked out and Fe was washed with ...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the frequency of the ultrasound described in Step 1 is 50 Hz-600 Hz. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: this embodiment is different from one of specific embodiments one to two: the Fe described in step one 3 o 4 The particle size of the nanoparticles is 50nm-1000nm. Others are the same as one of the specific embodiments 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com