Patents

Literature

255 results about "Poly(N-isopropylacrylamide-co-acrylamide)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Temperature responsive intelligent facial mask and method for preparing same

InactiveCN1883438AInhibit high temperature dehydrationAct as a supportCosmetic preparationsToilet preparationsSmart hydrogelsCellulose fiber

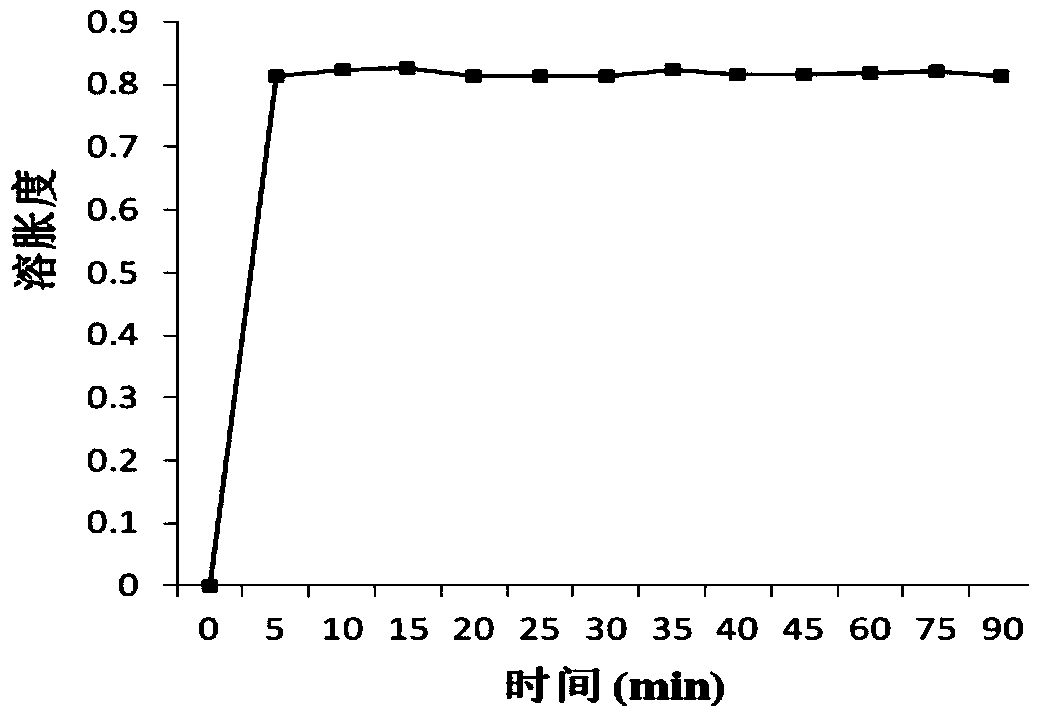

A temperature responsive intelligent face mask and preparation method thereof wherein a chitosan modified temperature sensitive isopropyl acryl amide / polyurethane copolymer hydrogel is grafted to a cellulose fiber. The advantages lie in that the intelligent hydrogel can swell and contract reversibly near body temperature, and the high-temperature dehydration phenomenon may be inhibited by the introduction of the polyurethane, the non-woven fabric exerts a supporter function by grafting the isopropyl acryl amide / polyurethane copolymer hydrogel thereto and as a result the strength of the gel is increased, the coupling of the natural chitosan to external surface of the gel film not only improves the face mask comfort, the skin affinity, but also offers the bacteria resistant ability. The gel face mask carries multiple nutrients and the carried nutrient and moisture may release intelligently through gel contraction under body temperature, meanwhile the temperature responsive intelligent face mask can be utilized in a plurality of times to satisfy the personalized requirement.

Owner:THE HONG KONG POLYTECHNIC UNIV

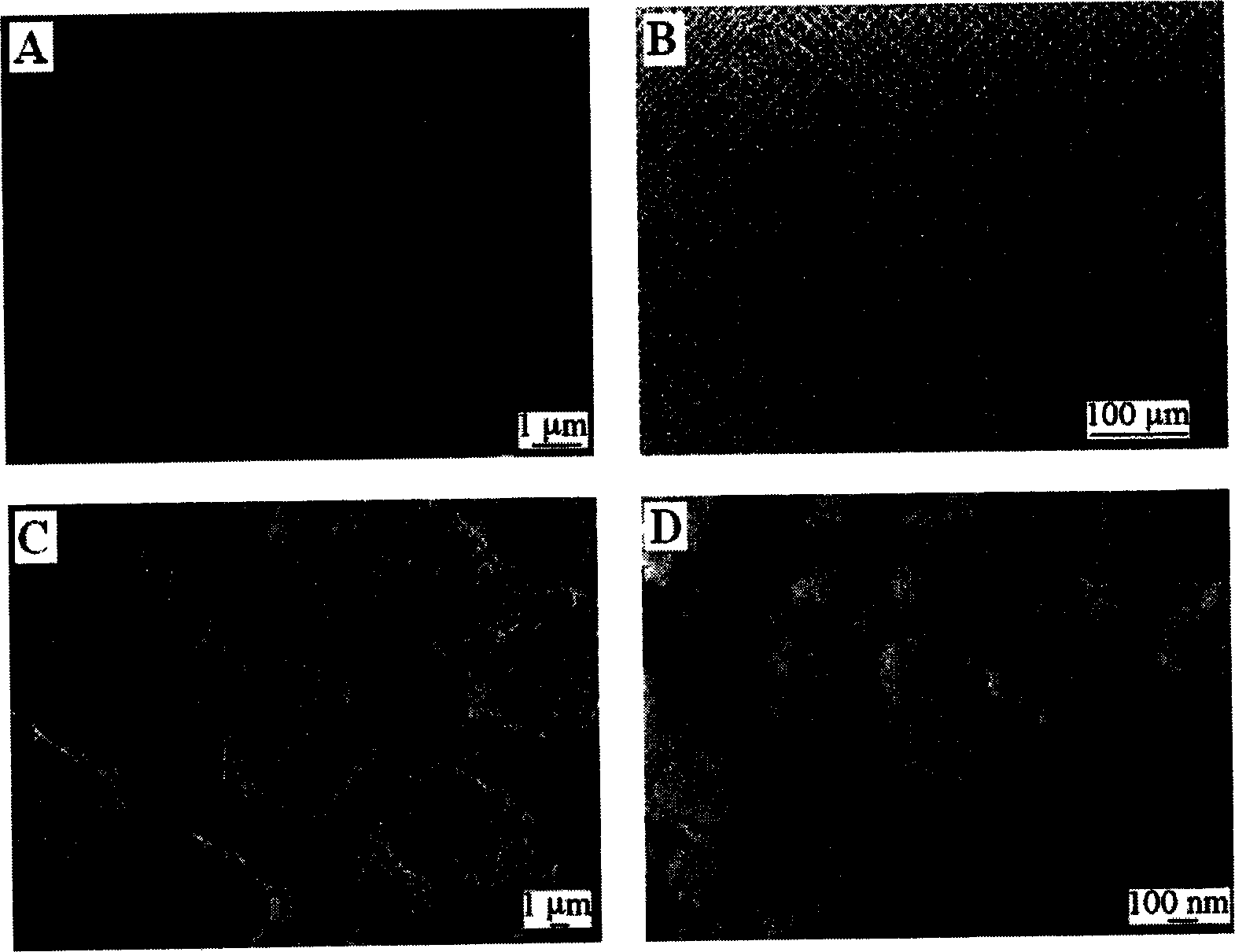

Soakage reversibly variable temperature-responsive copolymer film preparation method

InactiveCN1569933AEasy to prepareWide applicabilityPolymer scienceAtom-transfer radical-polymerization

The invention relates to a process for preparing temperature-responsive polymeric thin films which consists of, carrying out free radical polymerization reaction through surface triggering atom transition on smooth surfaces or rough surfaces with micrometer or nano structure, thus making the material surface have reversible soakage.

Owner:INST OF CHEM CHINESE ACAD OF SCI

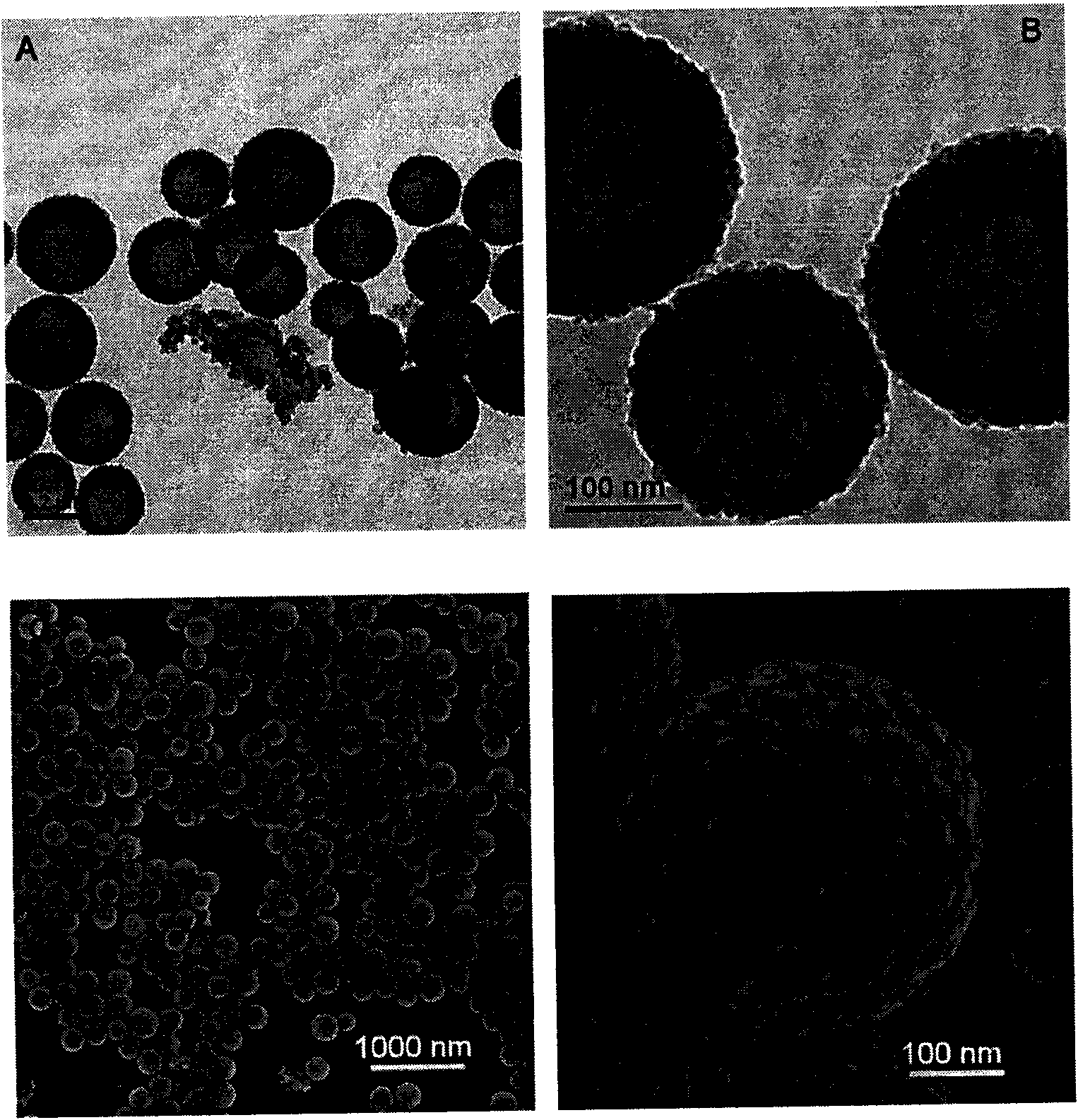

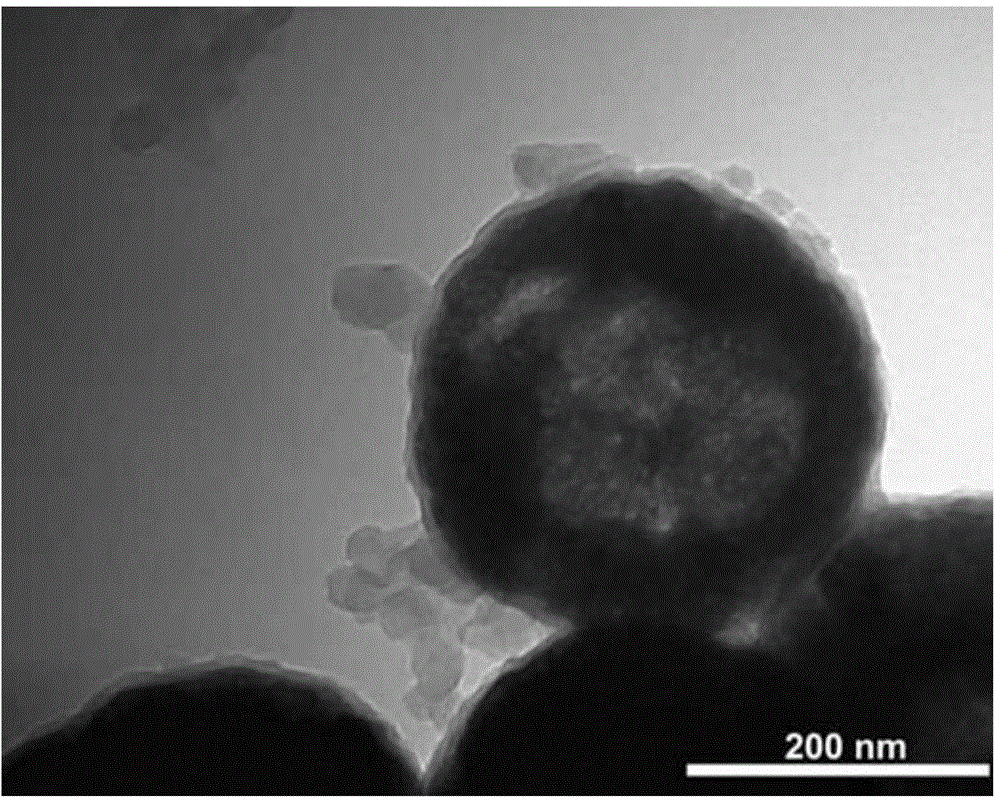

Hollow silica nanosphere and preparing method thereof

InactiveCN101559950ANot destructiveThe process is simple and easy to controlSilicaMicroballoon preparationOrganic solventReaction temperature

The invention discloses a method for preparing a hollow silica nanosphere by one step. The method comprises the following steps: mixing a poly-N-isopropyl acrylamide aqueous solution and an ethyl orthosilicate prehydrolysis solution at a temperature of 40 to 60 DEG C to react at a constant temperature for 160 to 180 hours; and carrying out ethanol washing, ultrasonic concussion, centrifugal separation and drying on a reaction liquid, and then obtaining the hollow silica nanosphere. The hollow silica nanosphere has a hollow core and mesoporous shell structure, the particle diameter is between 200 and 600 nm, and the shell thickness is between 30 and 100 nm. The invention also discloses the hollow silica nanosphere and the application. The method does not need to use an organic solvent to catalyze or further remove a template agent by high-temperature calcination or chemical corrosion, and can control the hollow nanosphere size and the shell thickness by simply changing the reaction temperature, the reaction time and the feed ratio.

Owner:ZHEJIANG UNIV

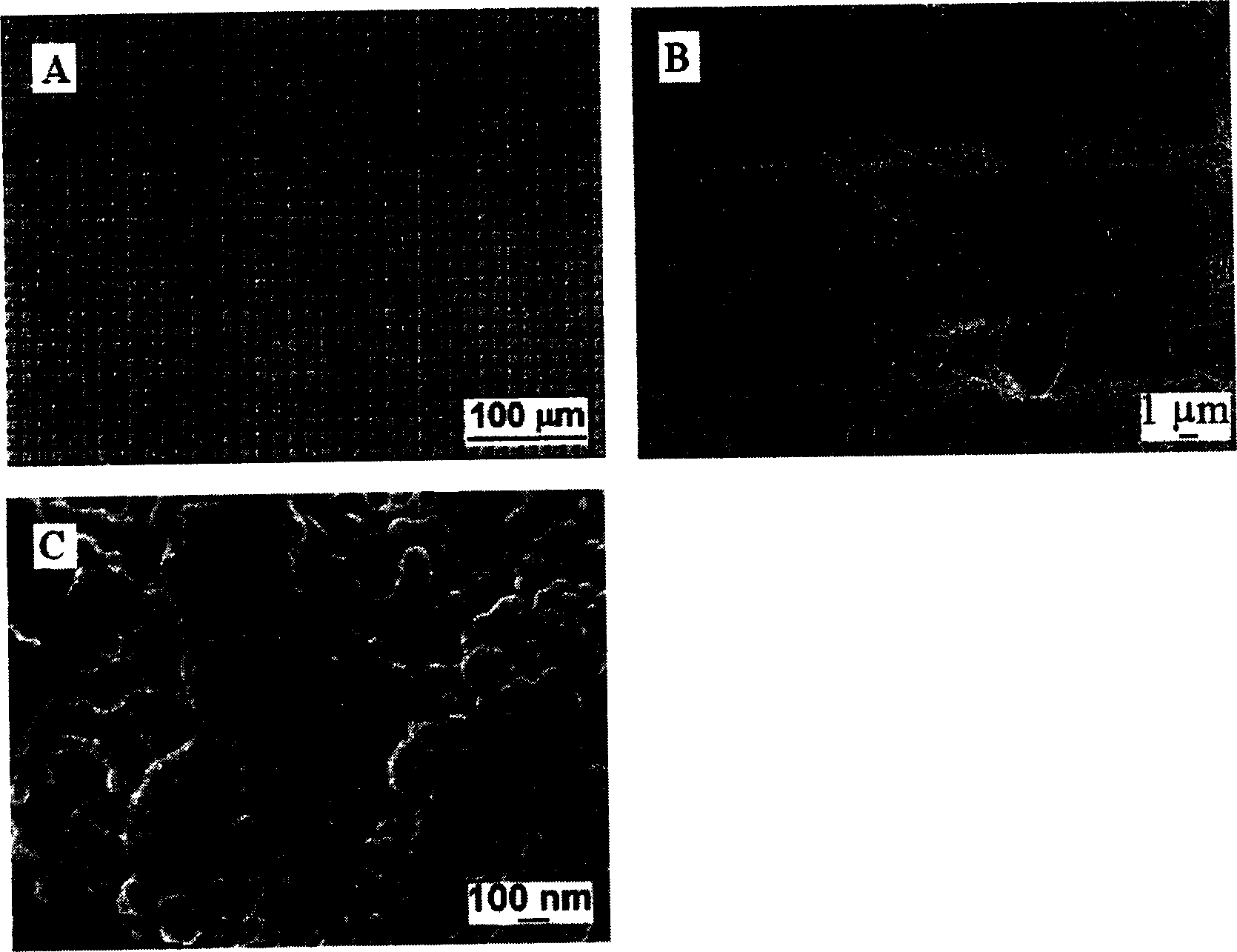

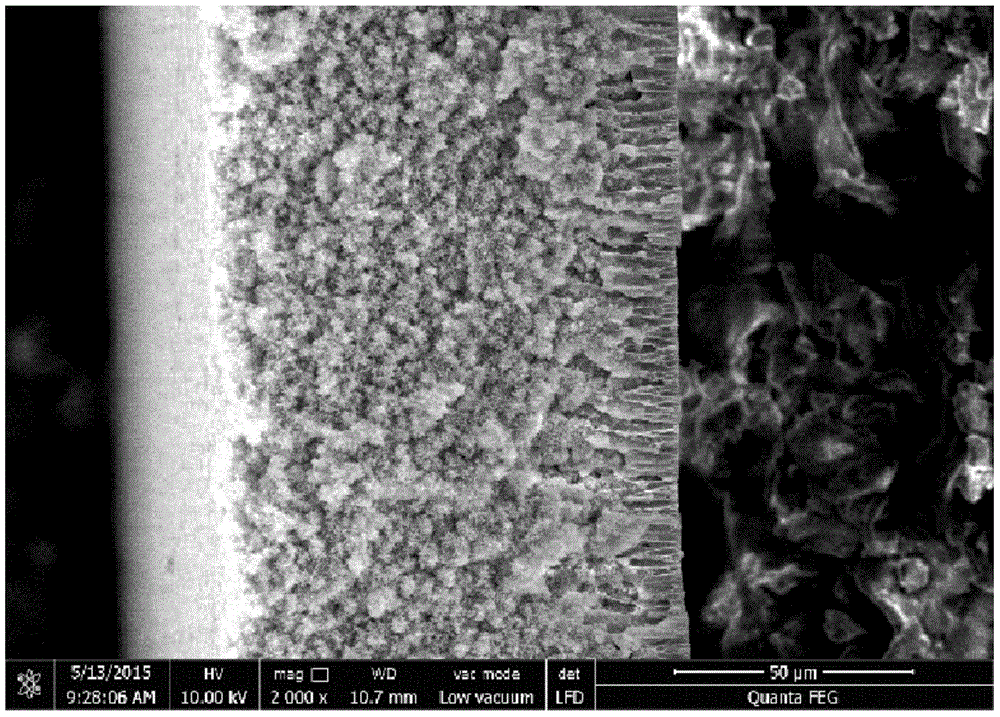

Thermo-sensitive poly N-isopropylacrylamide/polyurethane medicine-loading electro-spun fibrous membrane and preparation method thereof

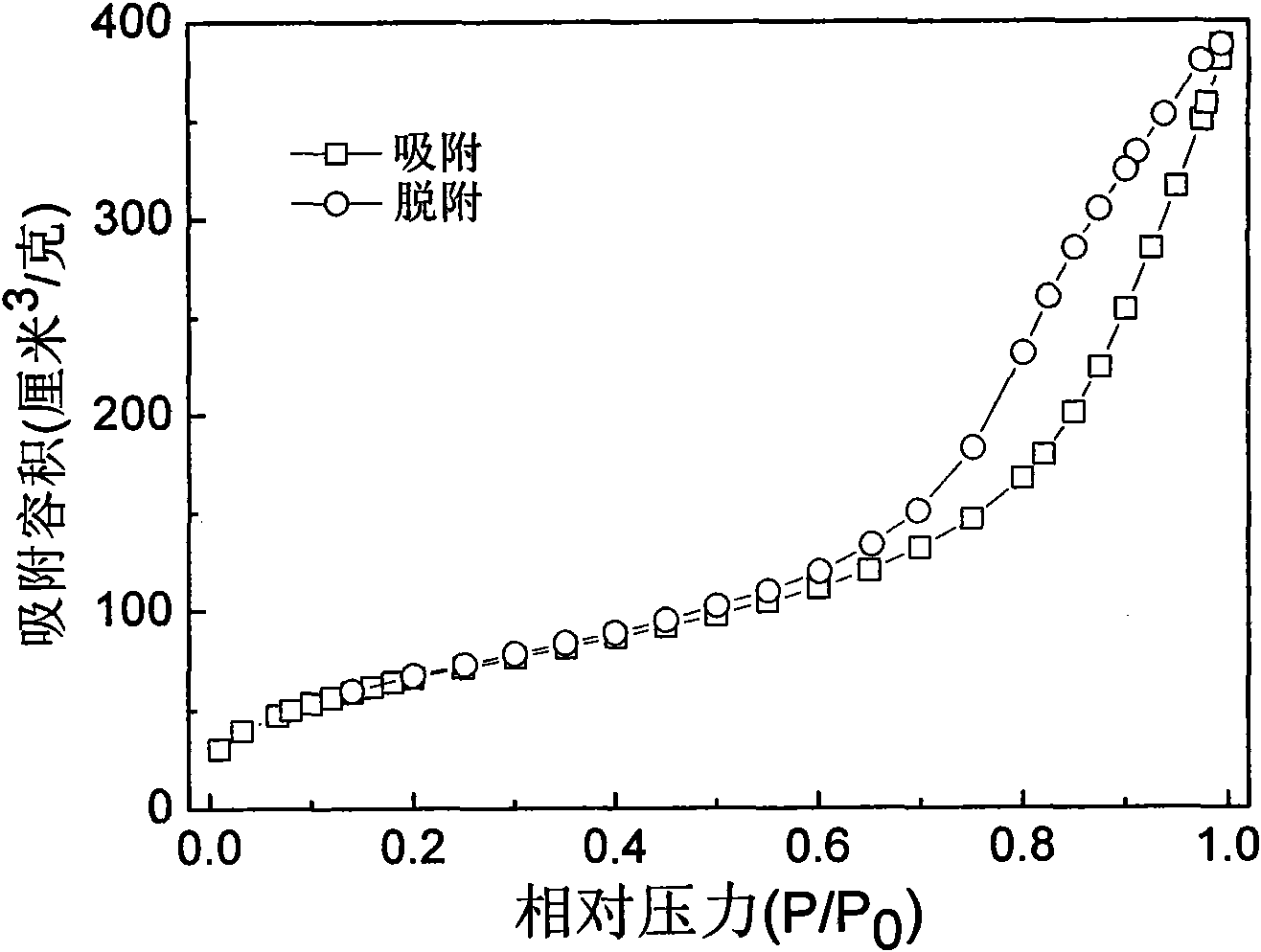

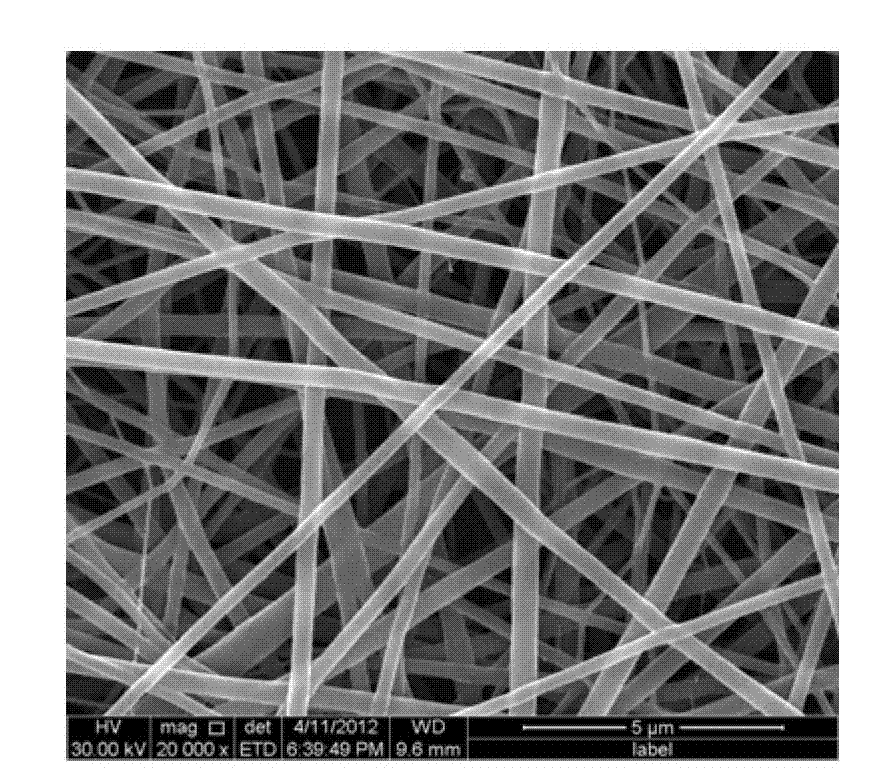

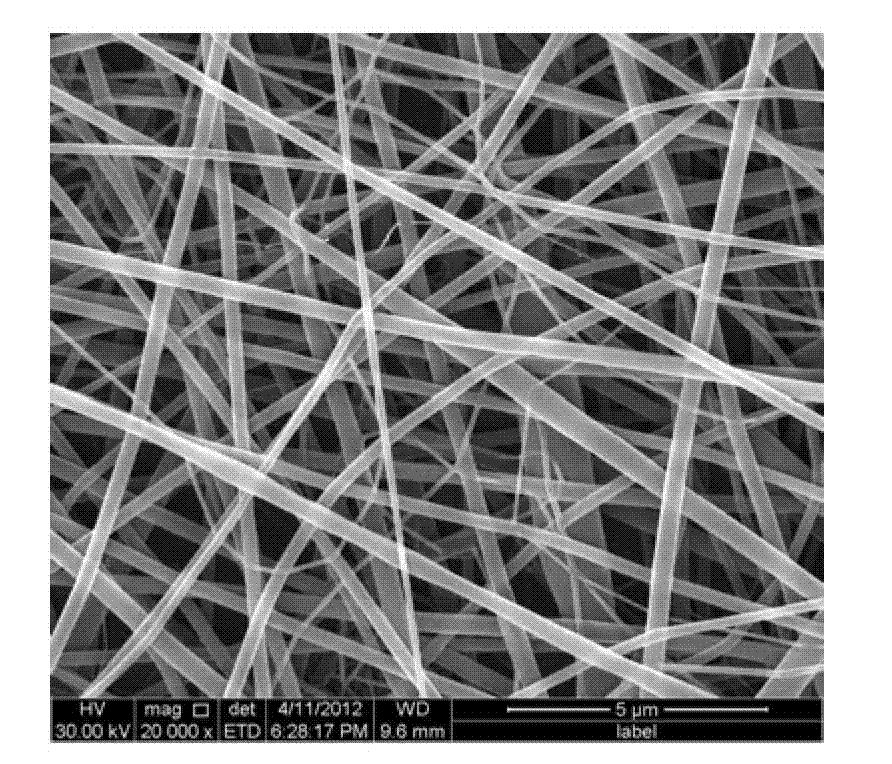

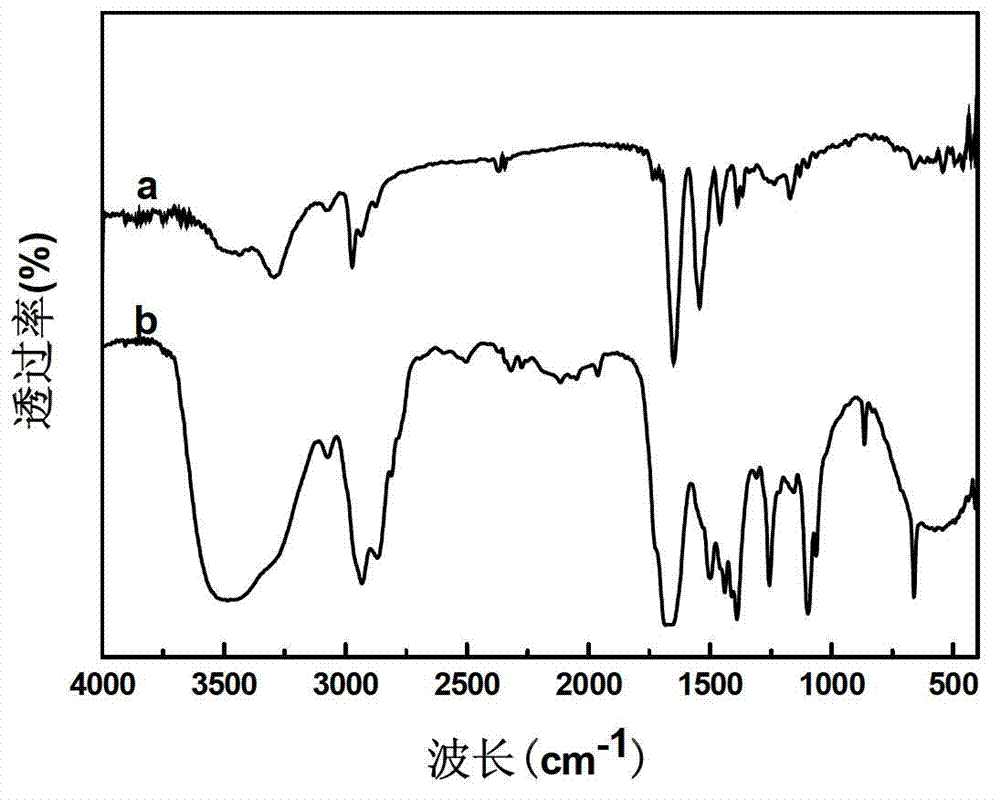

ActiveCN102733088ALarge specific surface areaHigh drug loadingOrganic active ingredientsFilament/thread formingN dimethylformamideElectrospinning

The invention relates to a thermo-sensitive poly N-isopropylacrylamide / polyurethane medicine-loading electro-spun fibrous membrane and a preparation method thereof, relating to a medicine-loading electro-spun fibrous membrane and a preparation method thereof and aiming to solve problems of poor mechanical property of existing poly N-isopropylacrylamide medicine-loading electro-spun fibrous membrane and no temperature sensitivity of a polyurethane medicine-loading electro-spun fibrous membrane. The thermo-sensitive poly N-isopropylacrylamide / polyurethane medicine-loading electro-spun fibrous membrane is prepared by poly N-isopropylacrylamide, polyurethane, N,N-dimethylformamide and a medicine; the preparation method comprises the following steps: 1, preparing static spinning solution; 2, dissolving the medicine so as to obtain the static spinning solution containing the medicine; 3, carrying out electrospinning; and 4, carrying out dry treatment to obtain the thermo-sensitive poly N-isopropylacrylamide / polyurethane medicine-loading electro-spun fibrous membrane. According to the invention, the preparation method is mainly used for preparing the thermo-sensitive poly N-isopropylacrylamide / polyurethane medicine-loading electro-spun fibrous membrane.

Owner:HARBIN INST OF TECH

Spatially controlled, in situ synthesis of polymers

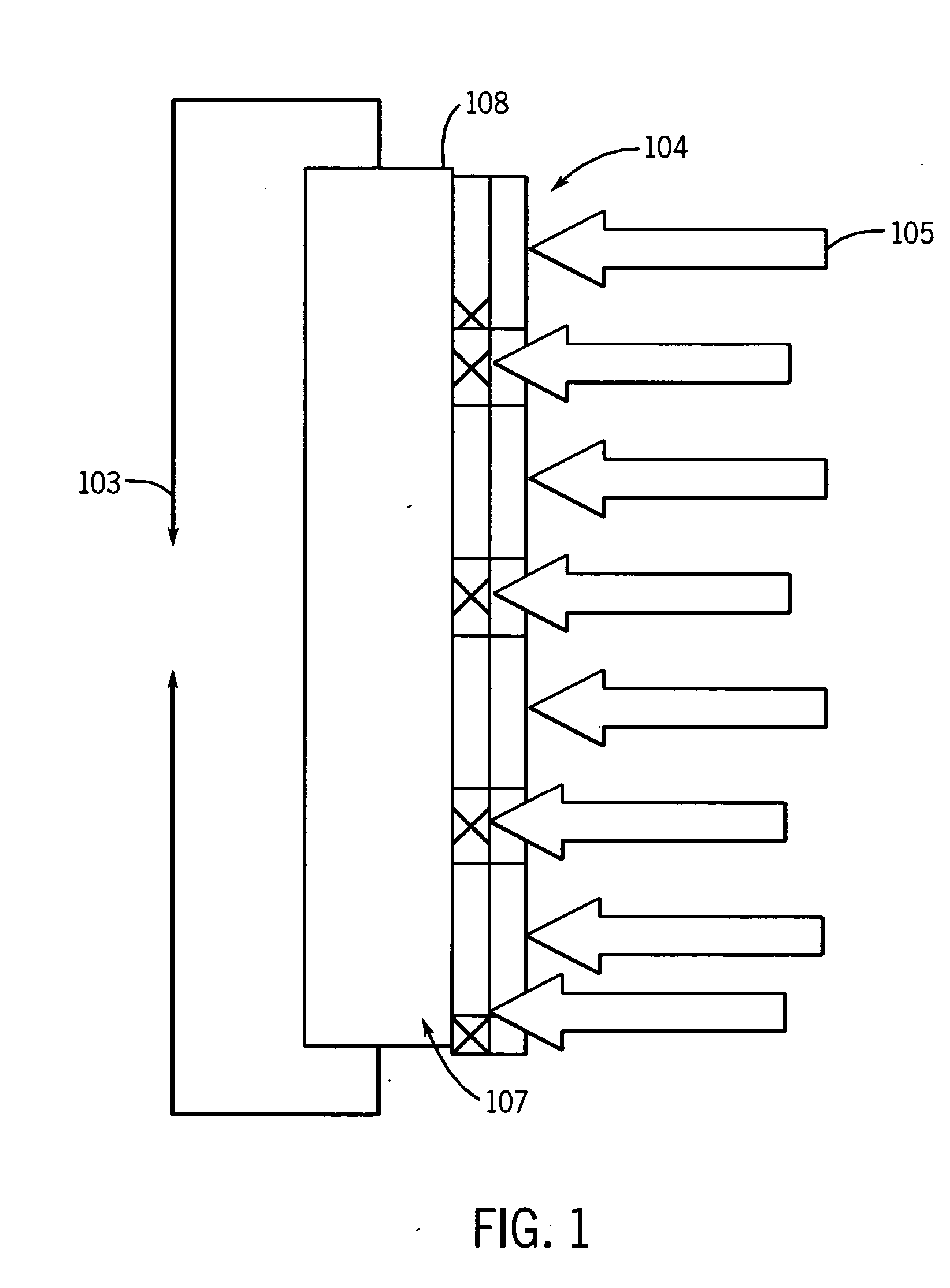

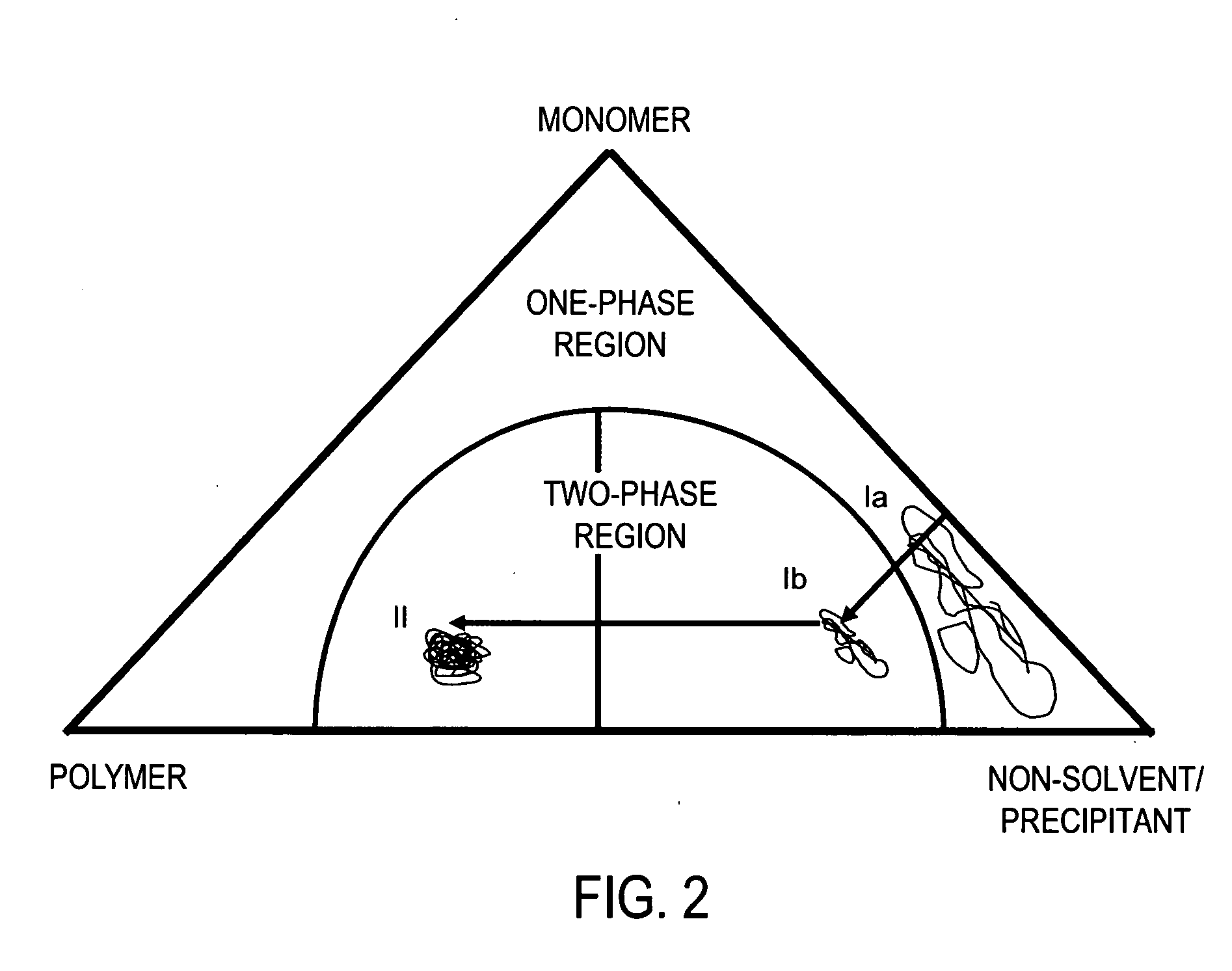

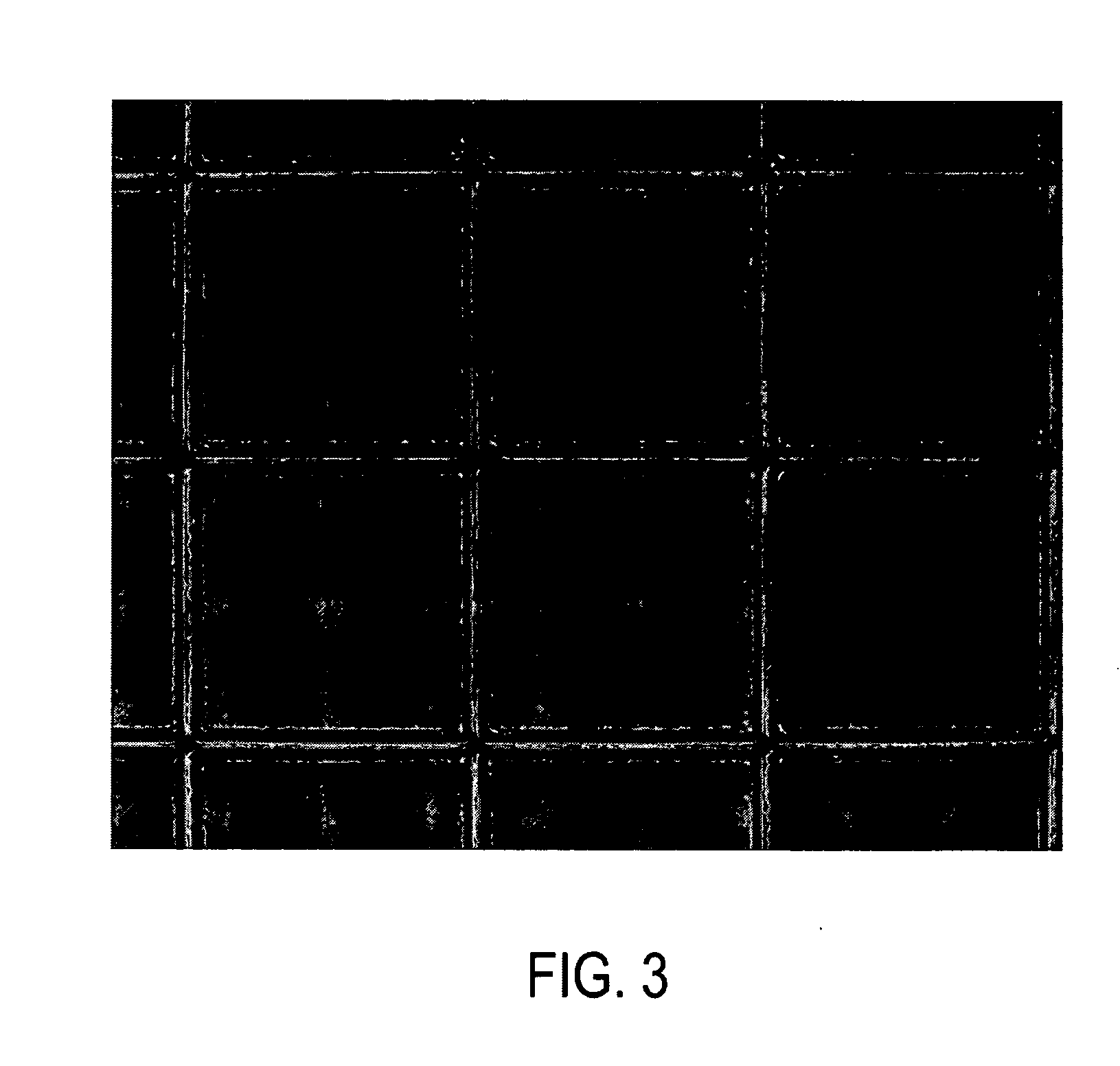

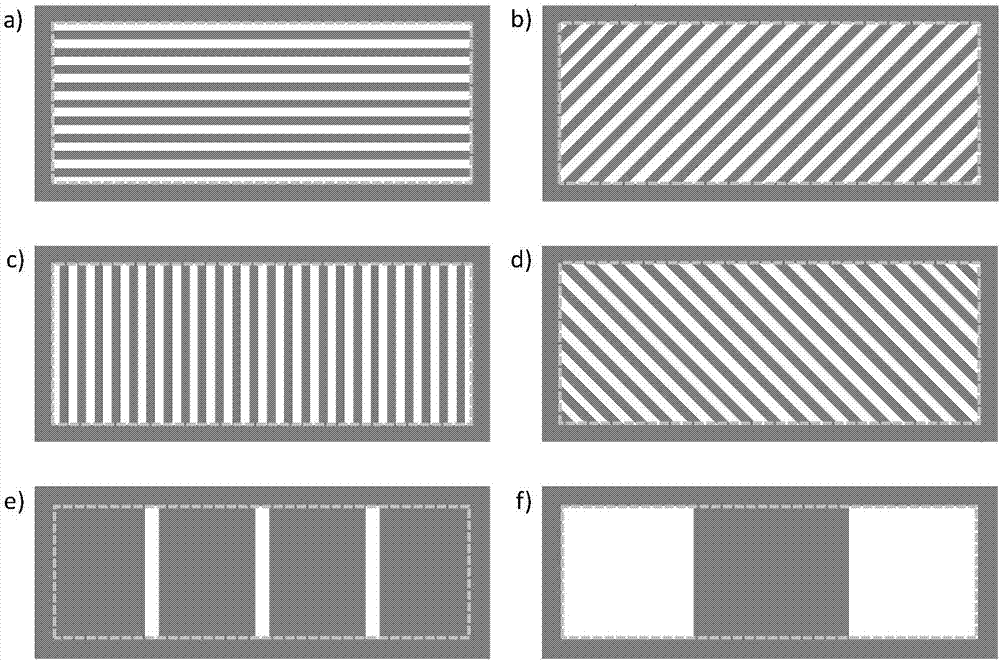

InactiveUS20050043428A1Improve structural stabilityHigh aspect ratioSurgical adhesivesMixing methodsGrid patternSolvent

An in situ polymer microstructure formation method. The monomer mixture is polymerized in a solvent / precipitant through exposure to ionizing radiation in the absence any chemical mediators. If an exposure mask is employed to block out certain regions of the radiation cross section, then a patterned microstructure is formed. The polymerization mechanism is based on the so-called free-radical retrograde-precipitation polymerization process, in which polymerization occurs while the system is phase separating above the lower critical solution temperature. This method was extended to produce a crosslinked line grid-pattern of poly (N-isopropylacrylamide), which has been known to have thermoreversible properties.

Owner:UCHICAGO ARGONNE LLC

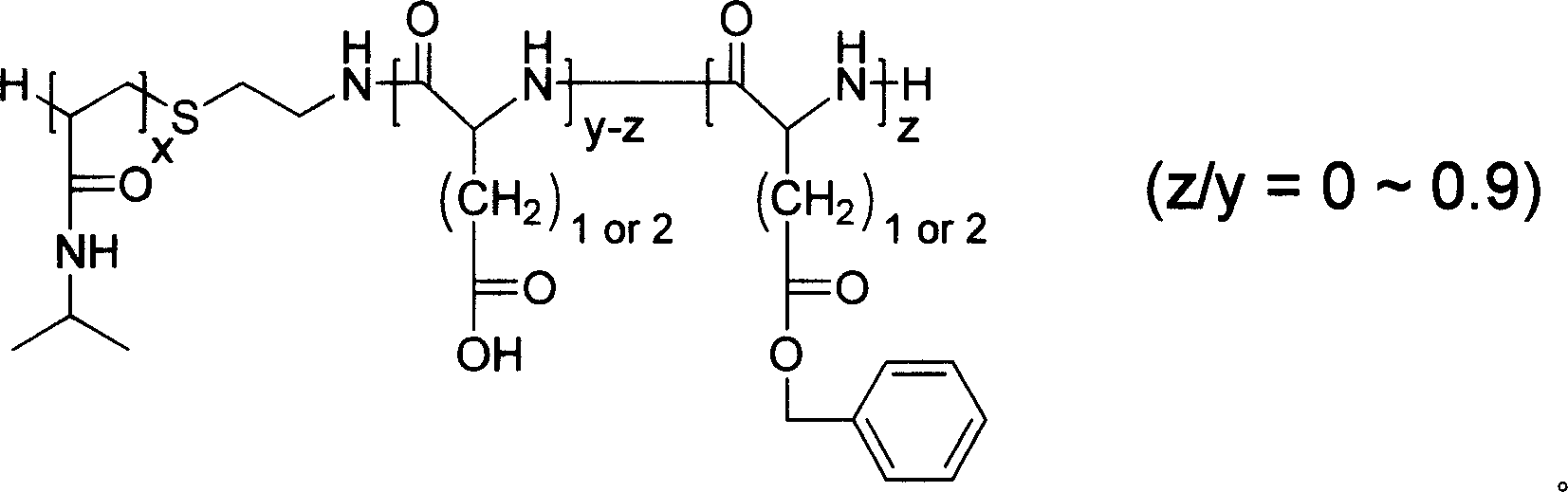

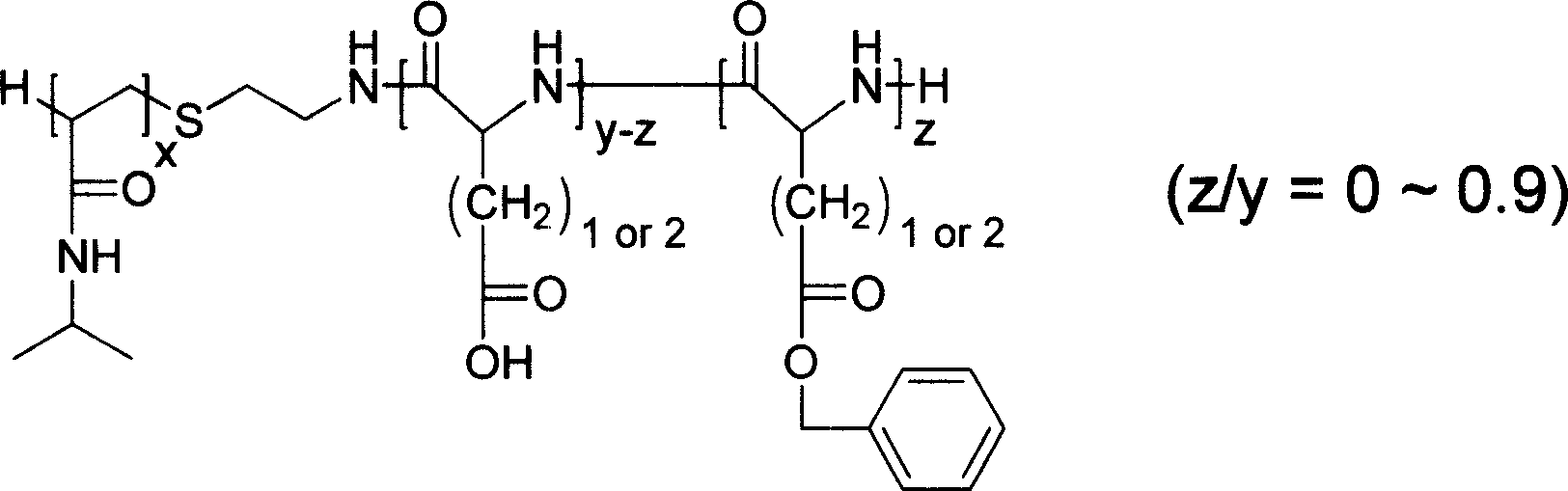

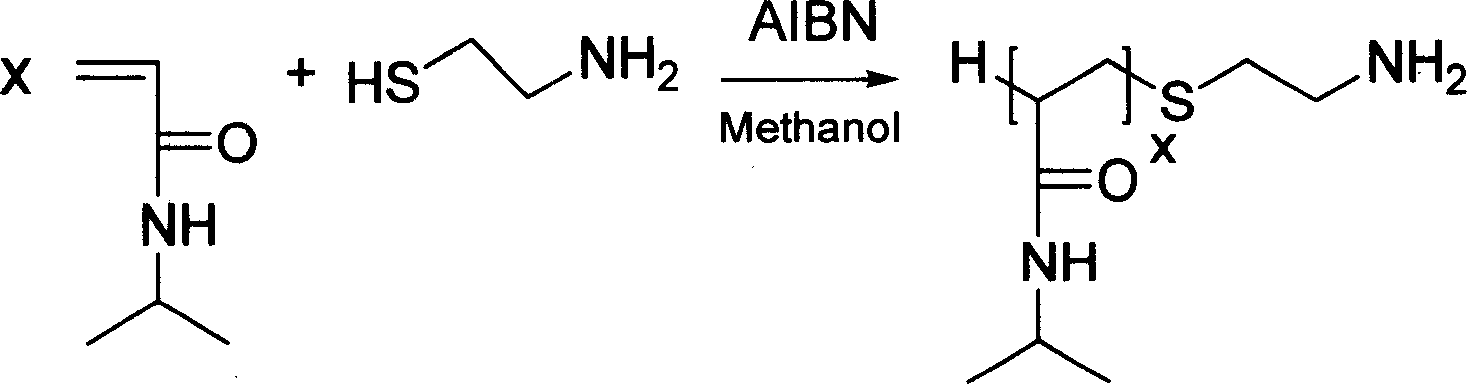

Poly N-isopropyl-acrylic-amide-poly amino-acid two-block copolymer and preparing method

InactiveCN101024697AOvercome the shortcoming of low critical transition pHNot toxicN isopropyl acrylamideDrug release

The invention relates to poly-N- isopropyl acrylamide-poly-amino acid two section copolymer and the manufacturing method. It is made from poly-N-isopropyl acrylamide that the equal molecular weight is 1000-10000. The poly-amino acid is poly-L-glutamic acid or poly-L- aspartic acid that the equal molecular weight is 1000-30000. The copolymer has double responsibility to temperature and pH in water solution. The pH responding range would alter around the content of benzyl group in poly-amino acid. And it could take biodegradation. The invention could be used as carrier that the in vivo target released to medicine and could be used as injectable intelligent responding hydrogel.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Easy-to-wash PVDF (polyvinylidene fluoride) ultrafiltration membrane and preparation method thereof

ActiveCN104971632ASimple structureHigh strengthSemi-permeable membranesPeptide preparation methodsPolymer sciencePolyethylene glycol

The invention discloses an easy-to-wash PVDF (polyvinylidene fluoride) ultrafiltration membrane and a preparation method thereof. The preparation method comprises the following steps: with triethyl phosphate as a solvent, ultrasonically dispersing a certain amount of poly N-isopropylacrylamide modified attapulgite in the solvent, adding PVDF powder and stirring violently till the PVDF powder is dissolved, adding a pore-foaming agent, namely polyethylene glycol, and uniformly stirring, and finally standing for defoaming to obtain a membrane casting solution; with water as a coagulating bath, preparing the ultrafiltration membrane by using an immersion precipitation phase conversion method. By introducing the poly N-isopropylacrylamide modified attapulgite into the PVDF ultrafiltration membrane, the unique nano-fiber structure of the attapulgite and the three-dimensional net structure formed by PVDF can be used to effectively improve the structure and strength of a pure PVDF ultrafiltration membrane, and the high hydrophilicity of the attapulgite is used to improve the permeability and hydrophilicity of the membrane; meanwhile, the ultrafiltration membrane also has the temperature sensitivity of poly N-isopropylacrylamide, and anti-pollution and easy-to-wash properties are realized.

Owner:HUAIYIN TEACHERS COLLEGE

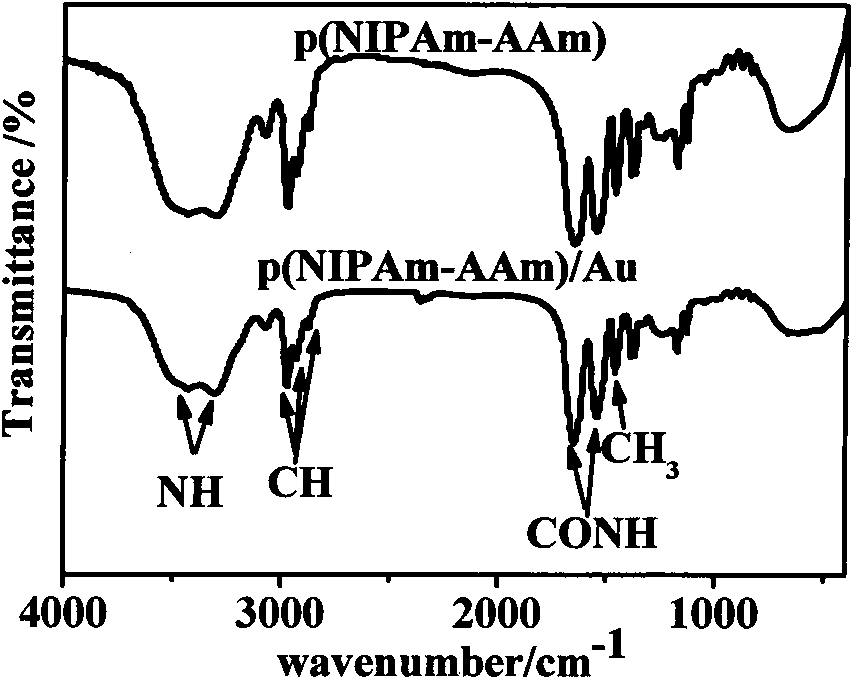

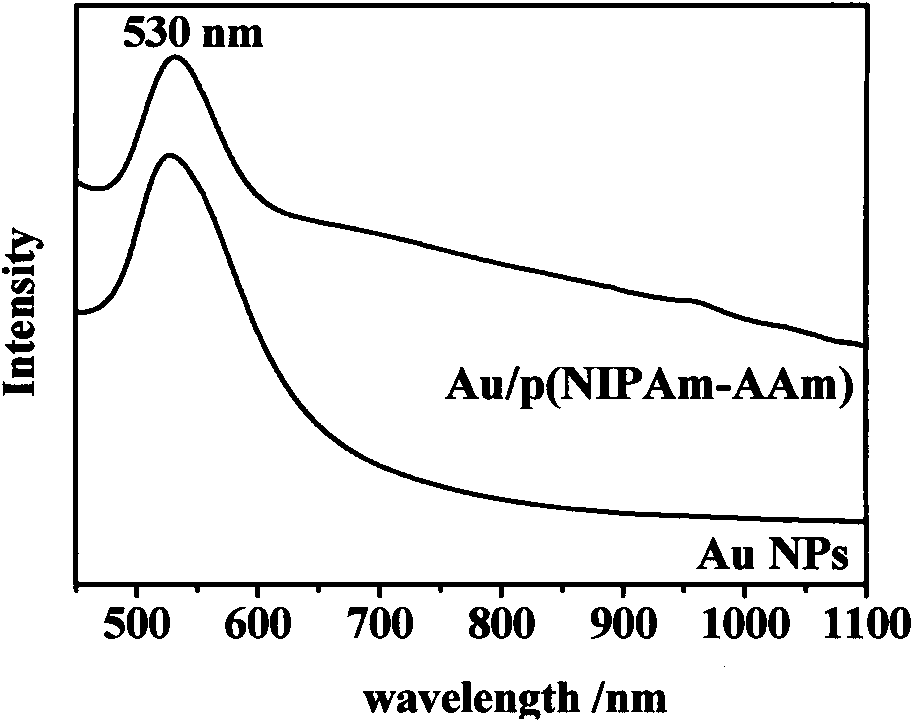

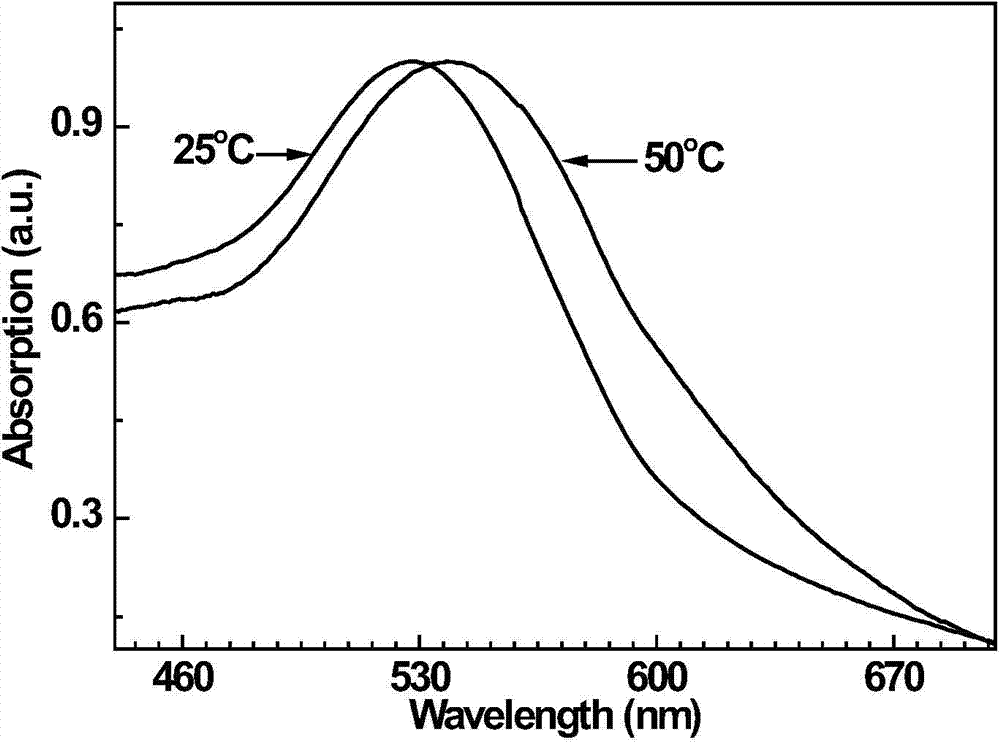

Temperature sensitive composite gold nano particles and preparation method and catalytic application thereof

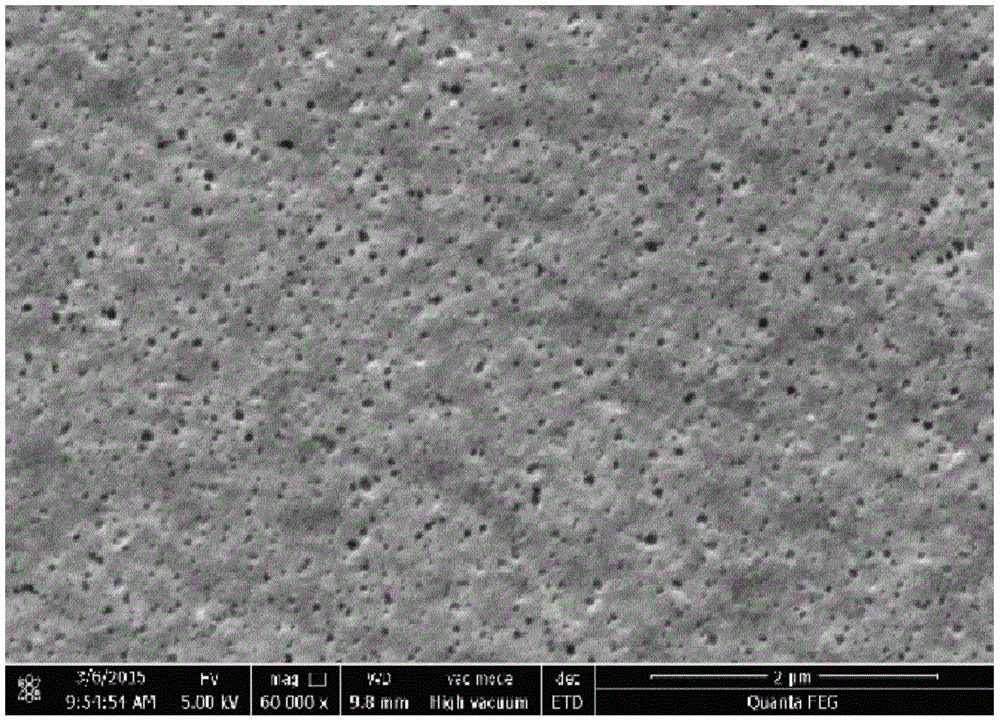

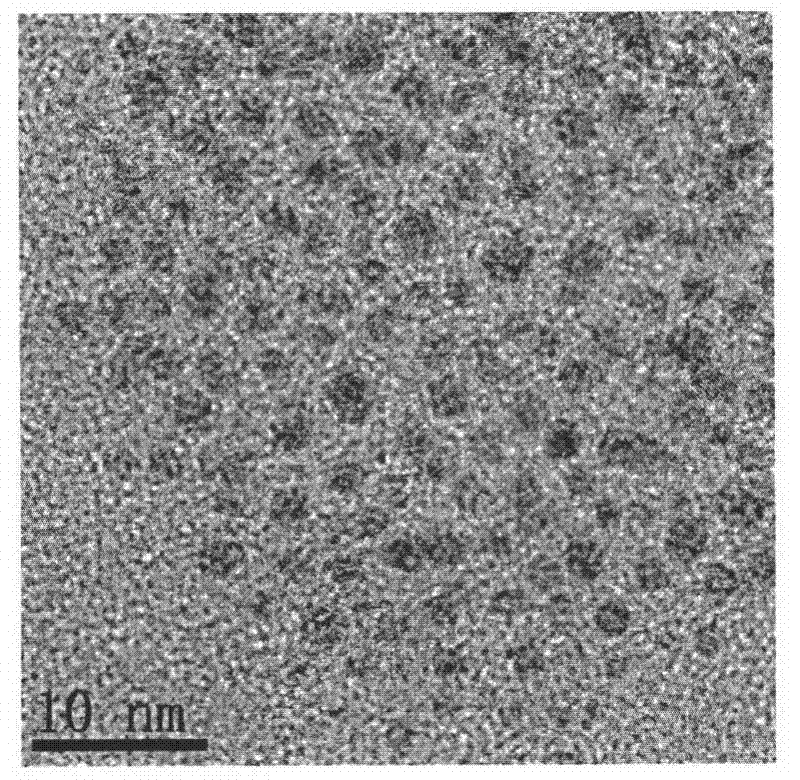

InactiveCN102286185AImprove stabilityGood temperature sensitivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDispersityGold particles

The invention relates to temperature sensitive composite gold nano particles and a preparation method and catalytic application thereof. The temperature sensitive composite gold nano particles are compounded by using nano gold particles and poly (N-isopropyl acrylamide) (PNIPAM) grafted glucan polymer, and the diameter of the particles is 1 to 20 nanometers; the preparation method comprises the following process of: mixing and shaking chloroauric acid serving as a precursor, the PNIPAM grafted glucan polymer serving as a nucleating agent and a stabilizing agent and sodium borohydride serving as a reducing agent to obtain a product; and the temperature sensitive composite gold nano particles serving as a catalyst are used for regulating and controlling the temperature of the nitrophenol reduction reaction process to control the process and the stop of the reaction. The invention has the advantages that: the preparation process is simple; and the prepared temperature sensitive composite gold nano particles have high dispersion, good stability and temperature sensitivity, and are used as the catalyst for controlling the nitrophenol reduction reaction process.

Owner:TIANJIN UNIV

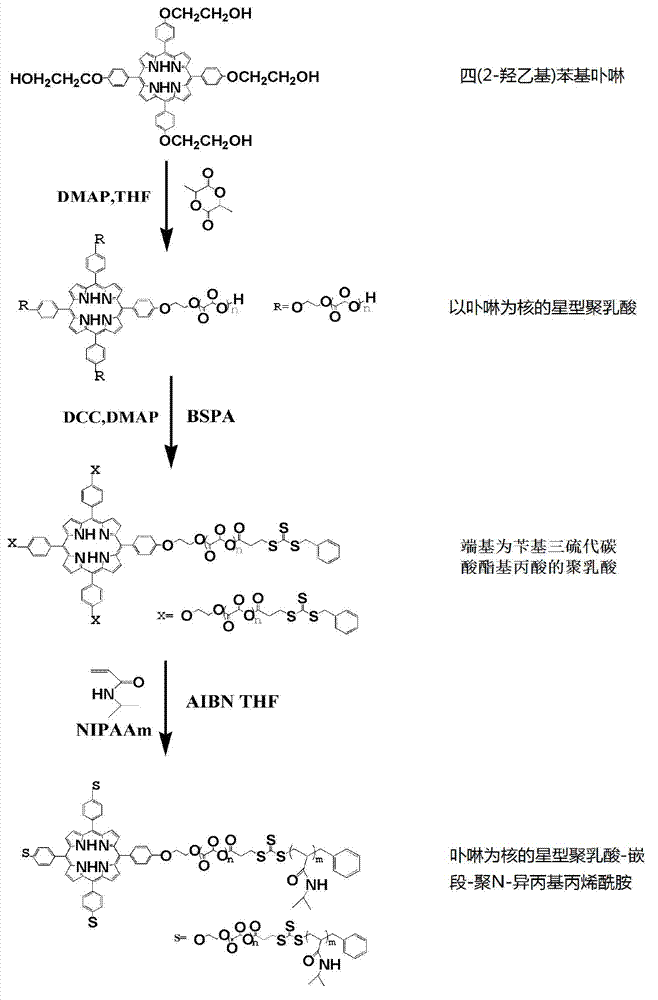

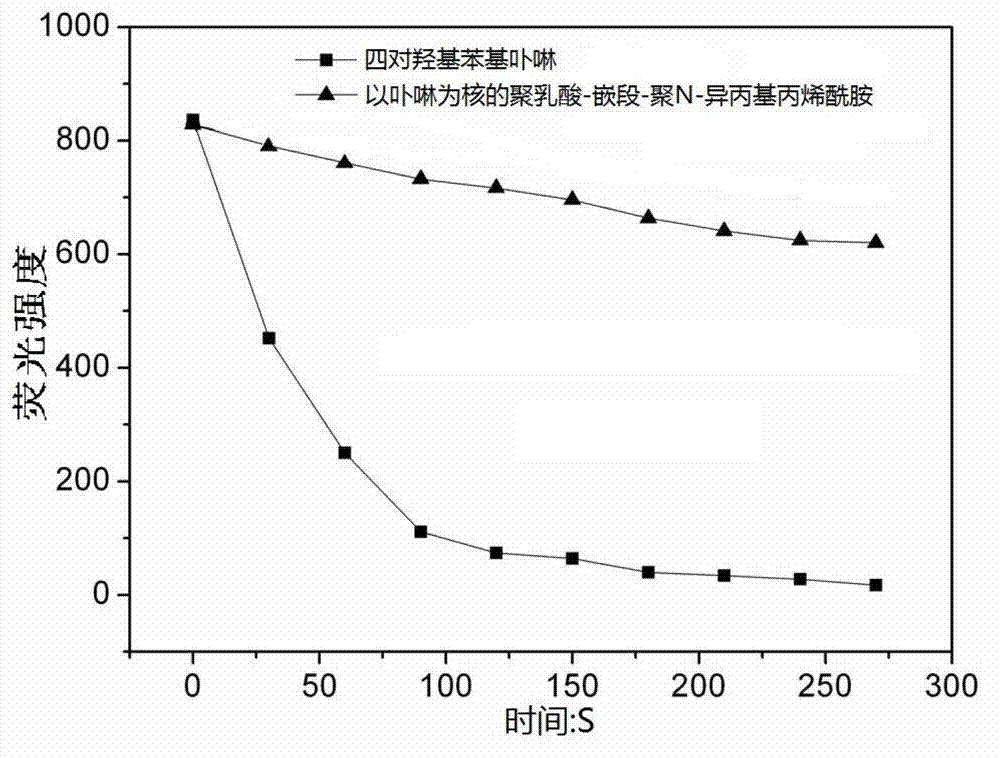

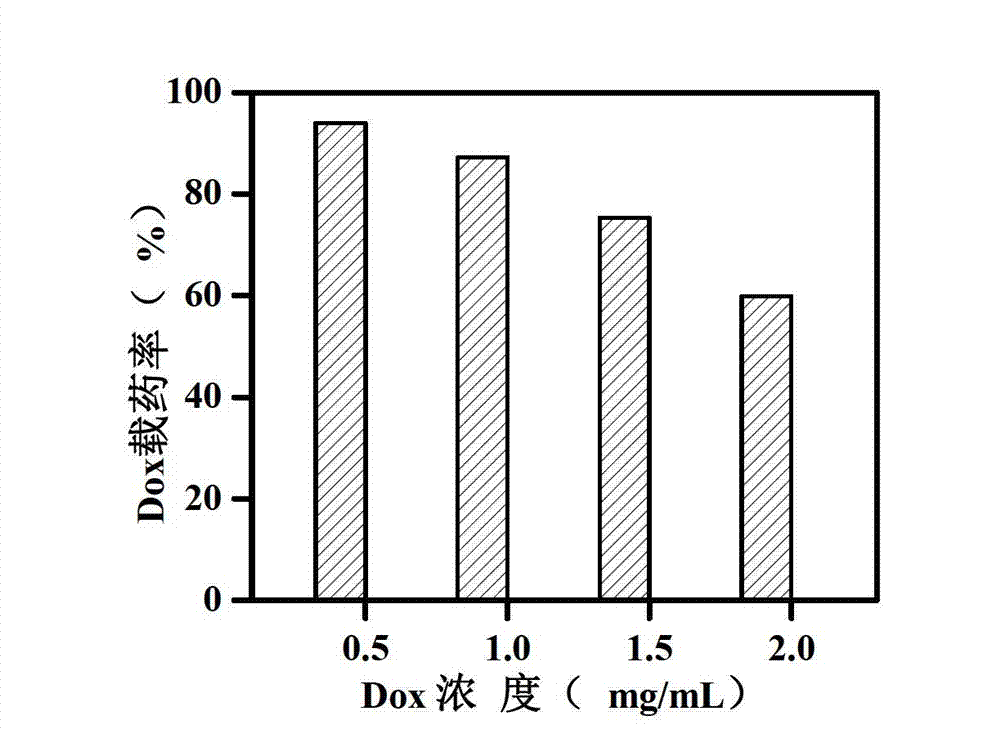

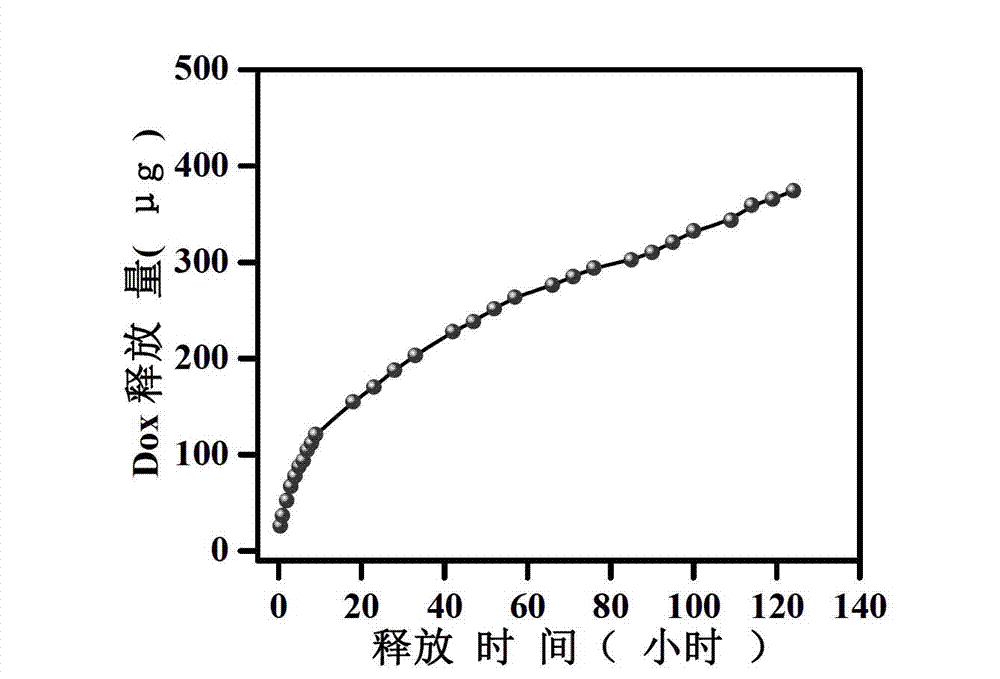

Method for synthesizing polylactic acid-block-polyN-isopropyl acrylamide temperature-sensitive material

InactiveCN103204981APrecise control over aggregate lengthConveniently preparedEnergy modified materialsPharmaceutical non-active ingredientsPoly-L-lactidePolymer science

The invention discloses a method for synthesizing a polylactic acid-block-polyN-isopropyl acrylamide temperature-sensitive material, and belongs to the technical field of amphipathy block copolymers. The method comprises the following steps of: initiating ring-opening polymerization of L-lactide by using tetra(2-hydroxyethyl) phenyl porphyrin to prepare hydroxylated star-shaped polylactic acid taking porphyrin as a core terminal; carrying out esterification reaction on the hydroxylated star-shaped polylactic acid taking porphyrin as the core terminal to obtain a macromolecular chain transfer agent; and preparing a novel star-shaped polylactic acid-block-polyN-isopropyl acrylamide temperature-sensitive material from the macromolecular chain transfer agent and a temperature-sensitive N-isopropyl acrylamide monomer by using a reversible addition-fragmentation chain transfer polymerization method. According to the method, a mild polymerization condition is adopted to facilitate the preparation of the star-shaped polylactic acid-block-polyN-isopropyl acrylamide temperature-sensitive biological material with polyN-isopropyl acrylamide adjustable in length and porphyrin as a core.

Owner:JIANGSU UNIV

Magnetic nano-composite microsphere based on cellulose base template and preparation method and use of magnetic nano-composite microsphere

ActiveCN103028116AFerromagneticHigh drug loading rateInorganic non-active ingredientsCellulosePolymer science

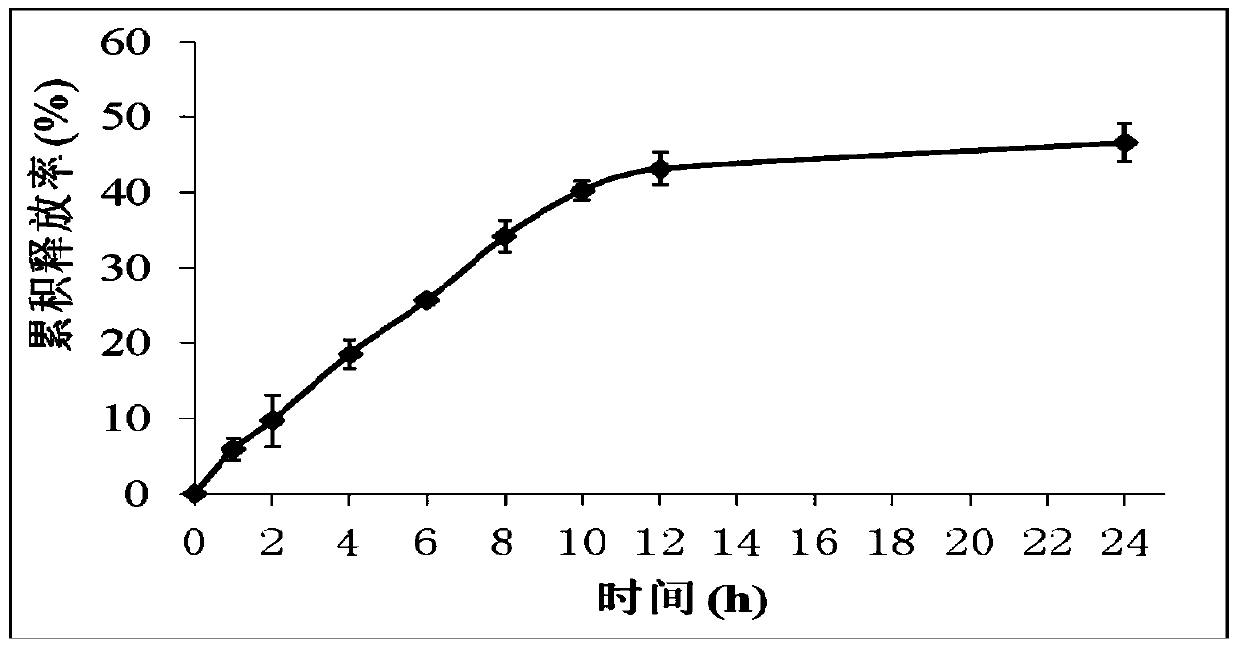

The invention discloses a magnetic nano-composite microsphere based on a cellulose base template and a preparation method and the use of the magnetic nano-composite microsphere. The magnetic nano-composite microsphere comprises a hollow poly-N-isopropyl acrylamide-polyacrylic nanocapsule and is loaded with Fe3O4 magnetic particles; and the average size of the composite microsphere is 200 to 2,000 nanometers. The preparation method comprises the following steps: a natural polymer hydroxy propyl cellulose-polyacrylic colloidal particle is taken as a template to obtain a hollow poly-N-isopropyl acrylamide-polyacrylic nanocapsule by precipitation polymerization; and then, Fe3O4 inorganic magnetic particles are loaded to the nanocapsule by an electrostatic self-assembly method and an in-site reduction method to prepare a Fe3O4 / poly-N-isopropyl acrylamide-polyacrylic magnetic nano-composite microspher. The composite microsphere has not only a certain of ferromagnetic property but also relatively high drug loading efficiency and good in-vitro release effect on water-soluble drugs, so that the composite microsphere can be applied to the field of biomedicines and biochemical engineering as a targeted drug delivery carrier.

Owner:重庆集凯科技服务有限公司

Preparation method of temperature response macromolecular gelatinous fibre material and products thereof

InactiveCN101748511AImprove water absorptionIncrease temperatureWet spinning methodsConjugated synthetic polymer artificial filamentsTemperature responseFiber

The invention relates to a preparation method of temperature response macromolecular gelatinous fibre material and products thereof, which can be applied on artificial muscles. Temperature response gelatinous fibre is produced by the mutual penetrating mixture of poly (N-isopropylacrylamide) and polyvinyl alcohol by a wet spinning process. The poly (N-isopropylacrylamide) and the polyvinyl alcohol are respectively 5 percent to 25percent by weight percent. The preparation method comprises the following three steps: 1, utilizing an in-situ polymerization method to polymerize the poly (N-isopropylacrylamide) in a polyvinyl alcohol water solution system, and preparing polyvinyl alcohol / poly (N-isopropylacrylamide) spinning solution; 2, taking saturation ammonium persulfate solution as coagulating bath, and utilizing the wet spinning process to prepare polyvinyl alcohol / poly (N-isopropylacrylamide) primary gelatinous fibre; and 3, carrying out vacuum heat treatment on the primary gelatinous fibre, and improving the heat resistance and structural stability of the primary gelatinous fibre. Compared with the traditional temperature response gelatinous fibre, the polyvinyl alcohol / poly (N-isopropylacrylamide) primary gelatinous fibre of the invention has good strength, rapid response speed, good biocompatibility, and wide application prospect on the artificial muscles and other biological fields.

Owner:TIANJIN POLYTECHNIC UNIV

Colloidal photon crystal composite film with humidity responsiveness and patterning, and method for preparing same

ActiveCN102616044ASimple processLow costDuplicating/marking methodsInksComposite filmFunctional monomer

The invention relates to a method for preparing a colloidal photon crystal composite film with humidity responsiveness and patterning by improving a humidity response speed through introducing poly (N-isopropylacrylamide). The method for preparing the colloidal photon crystal composite film comprises the following steps of: taking a mixed solution consisting of monodispersed emulsion particles, humidity responsiveness functional monomers, N-isopropylacrylamide monomers, a crosslinking agent, an initiator, a high boiling-point auxiliary and water as ink, printing the ink on the surface of a substrate with wettability in an inkjet manner, and obtaining a patterned colloidal photon crystal composite film composed of microdrop units with the humidity responsiveness, wherein the piled monodispersed emulsion particles are used as frames for the microdrop units with the humidity responsiveness, and crosslinked copolymers with the humidity responsiveness, obtained by crosslinking the humidity responsiveness functional monomers with the N-isopropylacrylamide monomers, are filled in the gaps of the frames.

Owner:INST OF CHEM CHINESE ACAD OF SCI

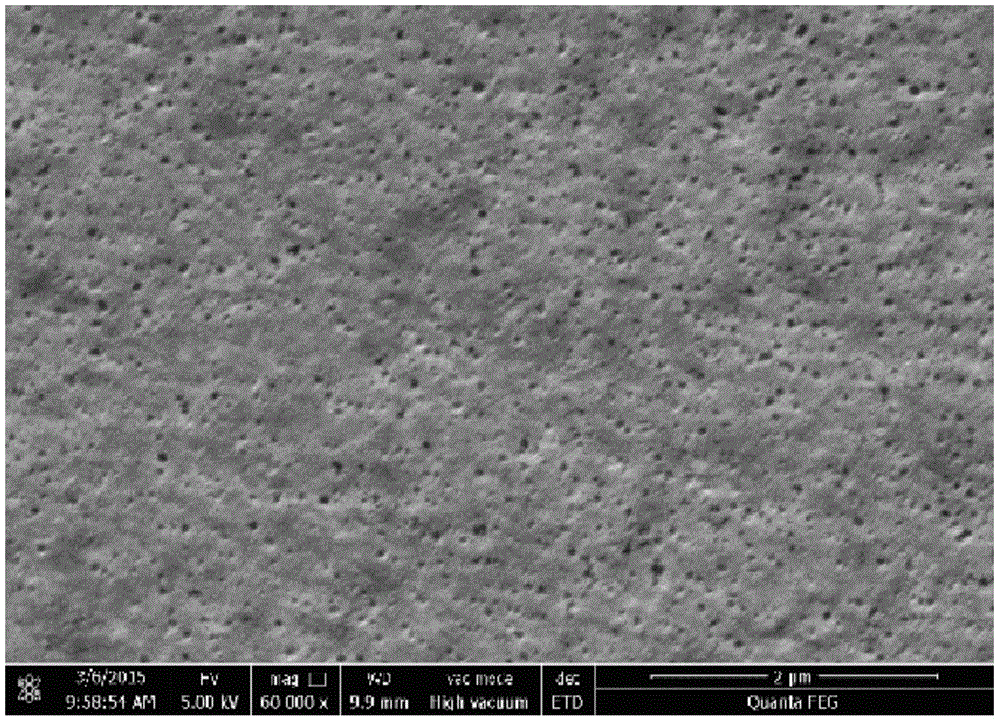

Temperature-sensitive filtering membrane with small pore size distribution and preparation method thereof

ActiveCN106000134AWide pore size distributionAvoid pollutionSemi-permeable membranesTemperature responseFiltration membrane

A temperature-sensitive filtering membrane with small pore size distribution is designed and prepared based on the thought of bionics by taking a metal chloride saline solution as a solvent in order to solve the problems that a large number of organic solvents hard to recycle are used in the traditional film preparation process, consequently, environmental pollution is caused, a polymeric membrane material is wide in membrane pore size distribution, and the membrane is in lack of responsiveness and is likely to be contaminated. Firstly, a temperature-sensitive polymer N-isopropylacrylamide is prepared in the metal chloride saline solution in a polymerization mode, and then N-isopropylacrylamide is homogeneously grafted with polyacrylonitrile to obtain a membrane casting solution; then the membrane casting solution is placed in a coagulating bath of water, metal ions and chloridions are gradually dispersed into the water, and a N-isopropylacrylamide grafted polyacrylonitrile polymer is subjected to phase transformation to form the membrane. The metal ions and the chloridions achieve a hole forming function, N-isopropylacrylamide and polyacrylonitrile are subjected to microphase separation, and a hydrophili channel subjected to ion hole forming is formed in the interface of N-isopropylacrylamide and polyacrylonitrile. The filtering membrane is expected to be used for the fields of fine separation, temperature response membrane on-off and the like.

Owner:HUNAN KEENSEN TECH CO LTD

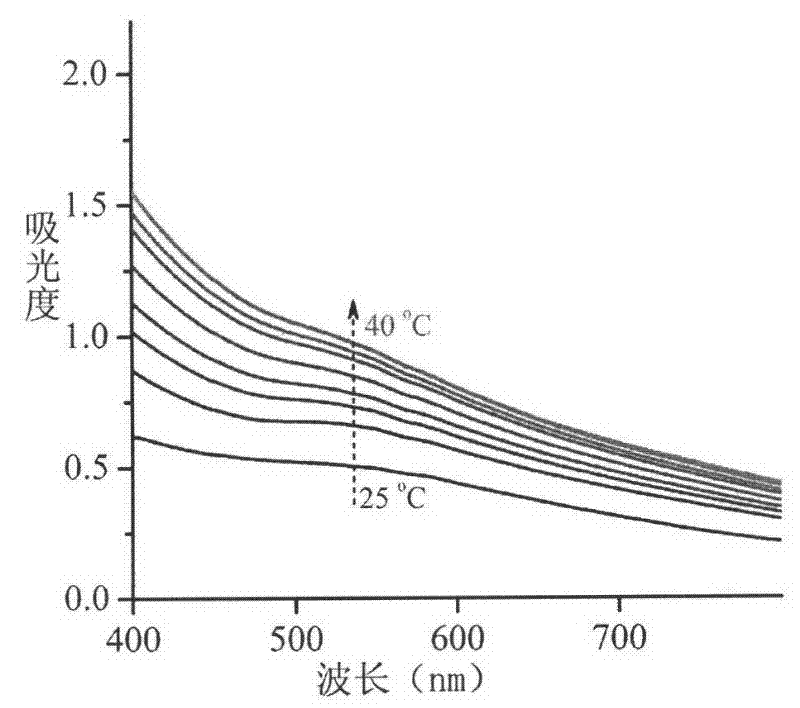

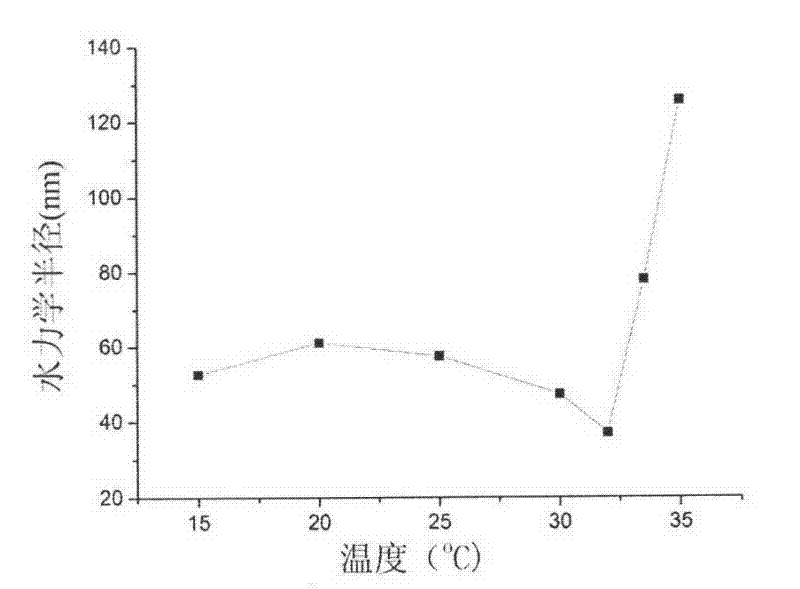

Light-response polymer microgel particle and preparation method thereof

The invention relates to the technical field of polymer, and specifically relates to a light-response polymer microgel particle and a preparation method thereof. An azobenzene group, which can generate isomerization under light irradiation, is grafted on poly(N-isopropylacrylamie-acrylic acid) copolymerized microgel through chemical bonding to prepare azobenzene-modified poly(N-isopropylacrylamie-acrylic acid) copolymerized microgel particles, which have a good light-response effect. The weight-average fluid mechanical radius of the microgel particles is increased by 20% after the microgel particles are irradiated by ultraviolet lights with a length of 360 nanometers. After the micro particles are irradiated by visible lights with a length of 465 nanometers, the weight-average fluid mechanical radius is recovered to the initial size. The operation of the preparation method is simple and easily-controllable, the experiment design and technological method are simple, and the cot is low.

Owner:NINGBO UNIV

Release mass transfer rate adjustable intelligent drug delivery carrier and preparation method thereof

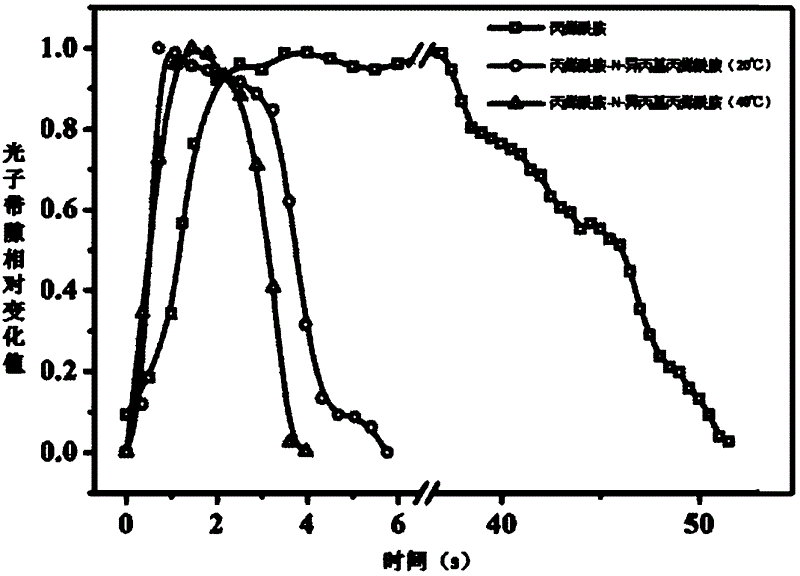

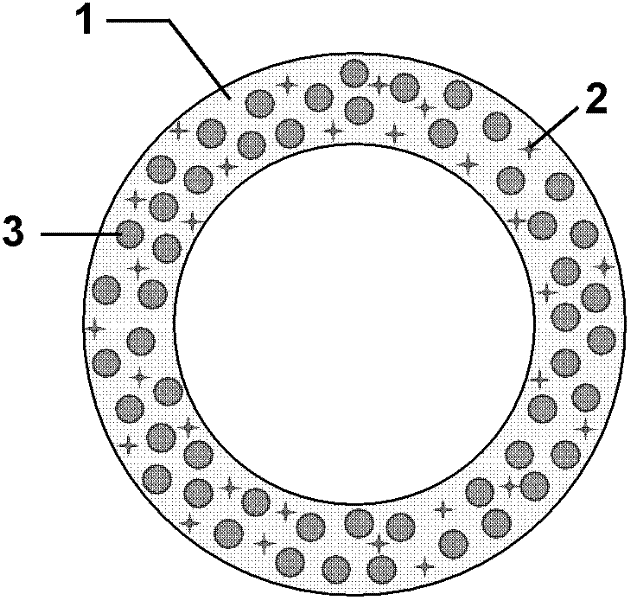

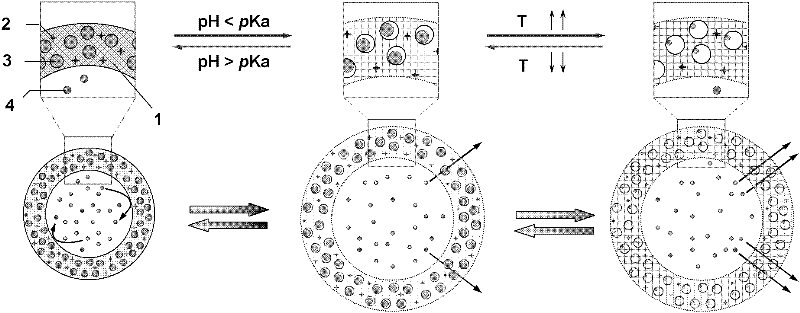

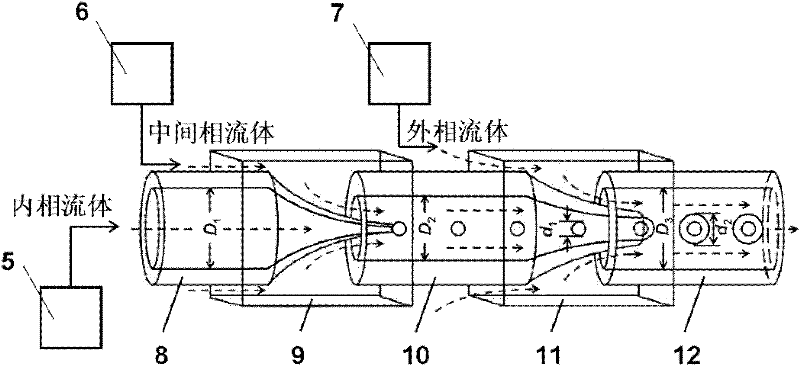

ActiveCN102258498AAvoid side effectsCompact structureInorganic non-active ingredientsMicrocapsulesMicrosphereN isopropyl acrylamide

The invention discloses a release mass transfer rate adjustable and controllable intelligent drug delivery carrier, which is a hollow spherical microcapsule. A membrane of the microcapsule mainly comprises poly[methacrylic-N, N-dimethylamino ethyl ester], super-paramagnetic Fe3O4 nanoparticles and poly(N-isopropyl acrylamide) temperature-sensitive sub-microspheres or poly[N-isopropyl acrylamide-copoly-acrylamide-copoly-allyl amine] temperature-sensitive sub-microspheres. A process for preparing the drug delivery carrier comprises the following steps of: (1) preparing the temperature-sensitivesub-microspheres; (2) preparing modified super-paramagnetic Fe3O4 magnetic fluid; (3) preparing intermediate phase fluid, inner phase fluid and outer phase fluid; and (4) preparing the drug delivery carrier.

Owner:SICHUAN UNIV

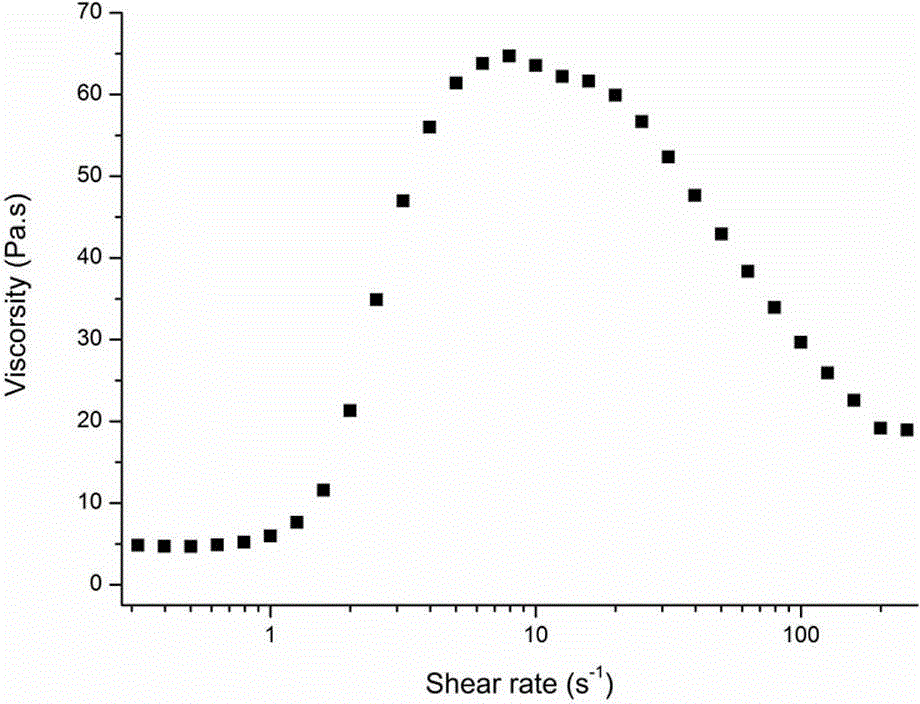

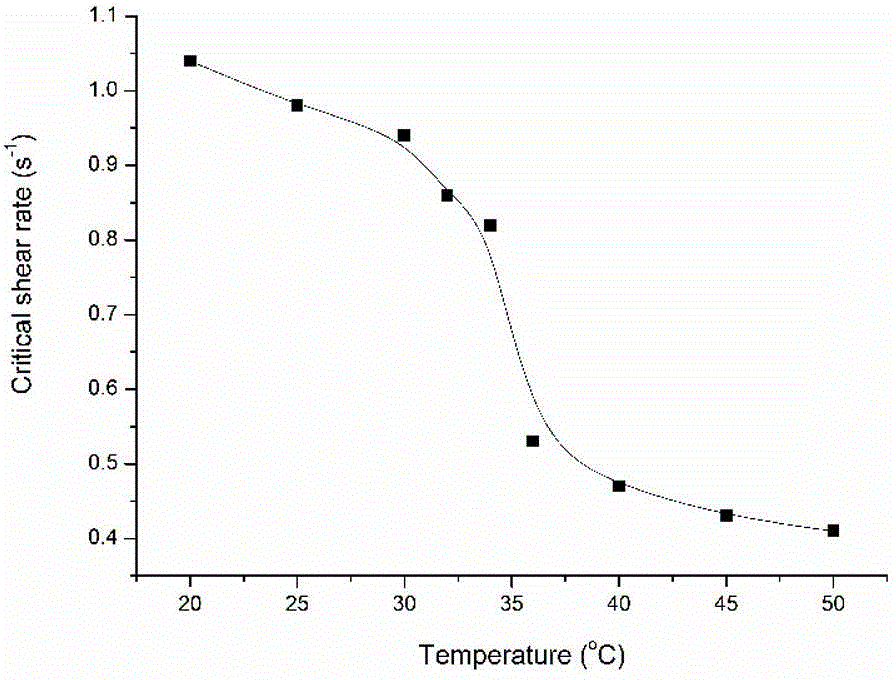

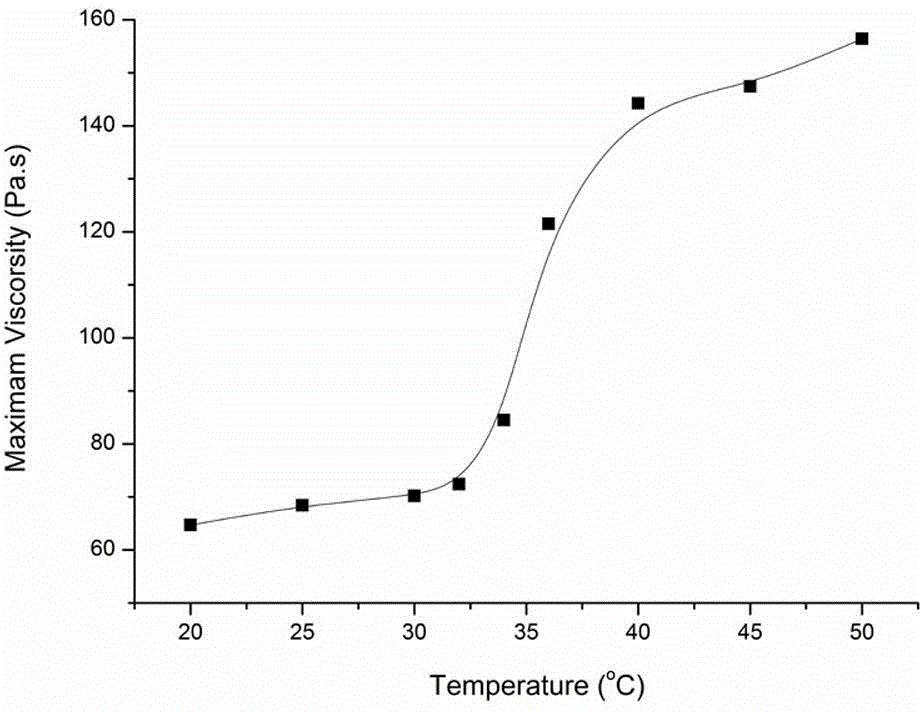

Preparation method of temperature sensitive hydrogel with shear thickening characteristic

The invention relates to a preparation method of a temperature sensitive hydrogel having an obvious shear thickening characteristic which can be controlled through temperature change. The hydrogel adopts poly(N-isopropylacrylamide) crosslinking network as a matrix, a certain concentration of an aqueous solution of polyethylene glycol is swelled in the matrix, and a certain mass fraction of poly(N-isopropylacrylamide) grafted nano-SiO2 microspheres are dispersed in the aqueous solution. The hydrogel has the obvious shear thickening characteristic, the shear thickening effect of the hydrogel can be controlled through temperature, and the hydrogel has obvious temperature sensitivity.

Owner:HUNAN ZHENQIU FIRE FIGHTING IND

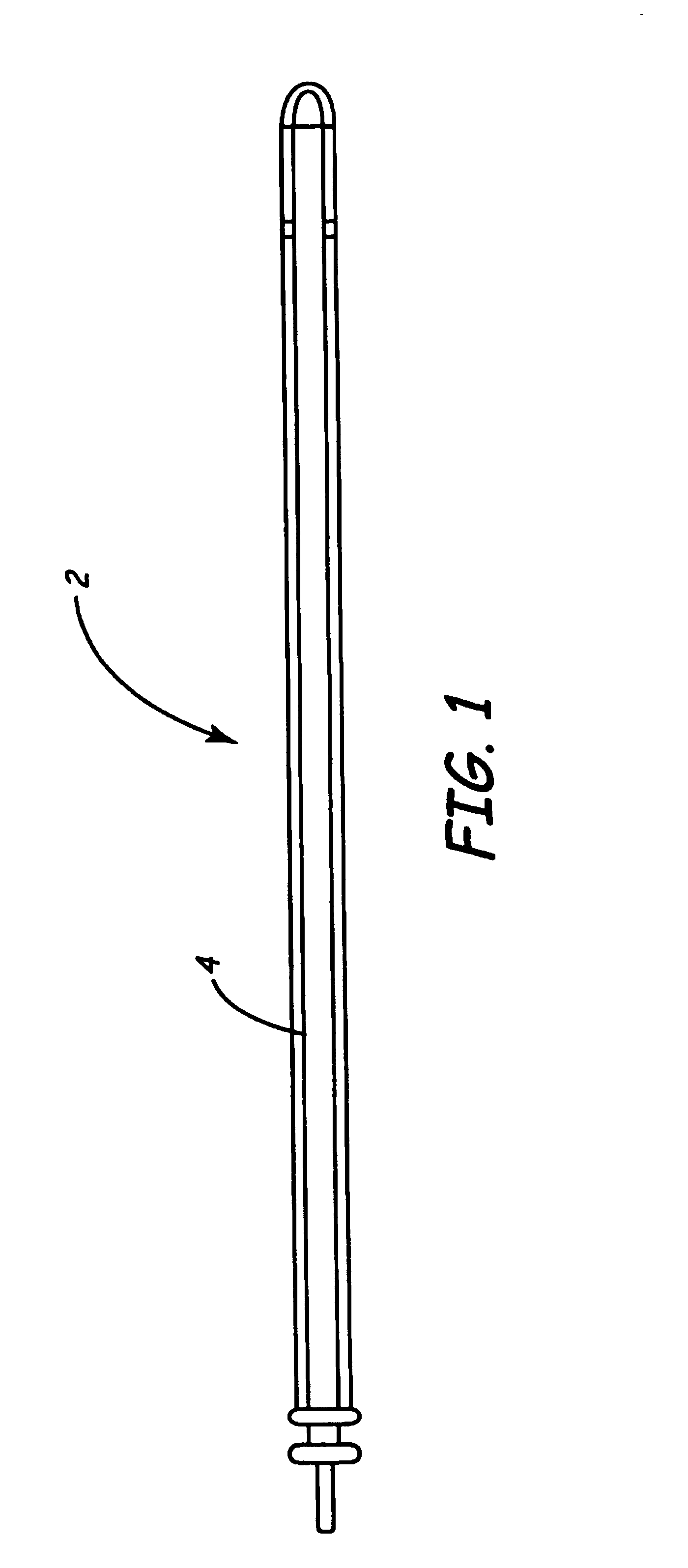

Enhanced chronic lead removal

An implantable medical device, perhaps a pacemaker lead, has a medical unit and a casing at least partially enclosing the medical unit. The casing is formed of a base polymer having surface modifying pendant groups formed of an acrylamide polymer or an acrylamide copolymer, perhaps polyisopropyl acrylamide. The base polymer may be a polyurethane, polyimide, fluoropolymer or polyolefin, for example.

Owner:MEDTRONIC INC

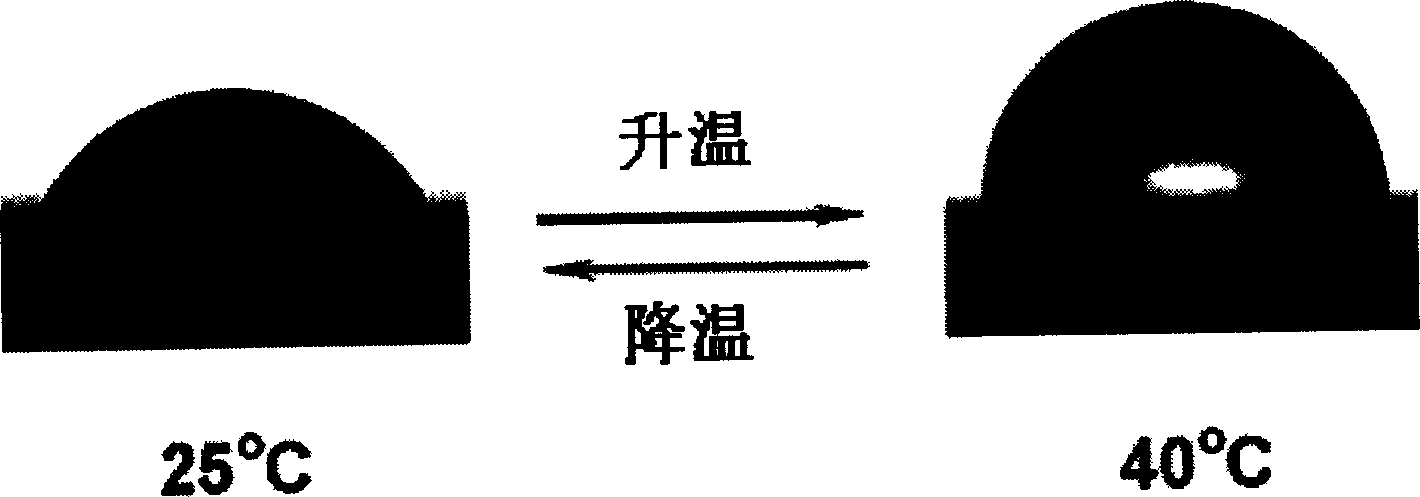

Preparation method and application of photo-thermal material Fe3O4/polydopamine/polyisopropyl acrylamide

The invention discloses a preparation method and application of a photo-thermal material Fe3O4 / polydopamine / polyisopropyl acrylamide, relates to a preparation method and application of a photo-thermal material, and aims to solve the technical problems that the remote operation for controlling liquid droplets on an extremely hydrophobic surface is not easy to achieve and free movement of the liquid droplets is limited in different directions. The preparation method comprises the following steps: I, preparing an Fe3O4 dispersion solution; II, preparing Fe3O4 / polydopamine / polyisopropyl acrylamide granules; III, preparing Fe3O4 / polydopamine-bromine; IV, preparing Fe3O4 / polydopamine / polyisopropyl acrylamide. The preparation method has the advantages that due to adoption of the photo-thermal material, operation in water, of organic liquid droplets is simple and feasible, the equipment is simple, the raw materials are convenient to obtain, the cost is low, the operation on the organic liquid droplets is achieved through remote laser control, and the Fe3O4 / polydopamine / polyisopropyl acrylamide material is in an extremely hydrophobic state under water, is free of pollution to the organic liquid droplets, and has wide application prospect.

Owner:HARBIN INST OF TECH

Artificial skin alternative material and preparation method thereof

The invention relates to an artificial skin alternative material and a preparation method thereof. According to the artificial skin alternative material, a polyurethane material serves as a base layer; a structure layer, which is formed by grafting, copolymerizing and modifying the polyurethane material and poly-N-isopropylacrylamide, is coated on the surface of the base layer; the molar ratio of the poly-N-isopropylacrylamide to the polyurethane material is (0.1-1):1; and the grafting ratio of the poly-N-isopropylacrylamide is 20 to 150 percent of the mass of the polyurethane material. The preparation method comprises the following steps of: performing bulk polymerization or solution polymerization on at least one of polyester polyol or polyether glycol serving as a hydroxyl donor component and an isocyanate component under the catalysis according to the molar ratio of an isocyanate group to the total hydroxyl of the hydroxyl donor of (0.8-1.8):1 to obtain the base layer polyurethane material; and grafting, copolymerizing and modifying the base layer polyurethane material and the poly-N-isopropylacrylamide to obtain the artificial skin. The artificial skin alternative material has an excellent mechanical property close to that of the skin and has certain temperature sensitivity. The artificial skin alternative material can be prepared from the hydroxyl donor component and the isocyanate component. The preparation method is easy and convenient to operate, low in energy consumption, low in cost and suitable for large-scale production.

Owner:SICHUAN UNIV

Preparation method for temperature-sensitive chitosan-based polyelectrolyte composite micelle

InactiveCN103205081ASimple manufacturing methodMild preparation conditionsPharmaceutical non-active ingredientsEmulsion deliveryFiltrationBiocompatibility Testing

The invention discloses a preparation method for a temperature-sensitive chitosan-based polyelectrolyte composite micelle. The preparation method comprises the following concrete steps: dissolving chitosan in an acetic acid solution, adding a temperature-sensitive monomer N-isopropylacrylamide under stirring, adding a water-soluble initiator under the protection of nitrogen, carrying out a reaction for 4 to 12 h at a certain temperature, subjecting a reaction solution to acetone precipitation and pumping filtration and carrying out drying so as to obtain chitosan-grafted poly(N-isopropylacrylamide); and dissolving the synthesized graft copolymer in distilled water with a certain pH value, adding a certain proportion of an anionic polyelectrolyte solution under stirring and carrying out a reaction for 12 to 48 h. The temperature-sensitive chitosan-based polyelectrolyte composite micelle prepared in the invention has good biocompatibility, temperature sensitivity and stability performance and uniform particle size distribution; the preparation method is simple, and reaction conditions are mild; and the temperature-sensitive chitosan-based polyelectrolyte composite micelle has a potential application value in fields like drug delivery, micro-reactors and biosensors and is especially applicable to controllable loading and releasing of drugs.

Owner:LUDONG UNIVERSITY

Nano-hydrogel drug carrier material with photosensitivity and temperature sensibility

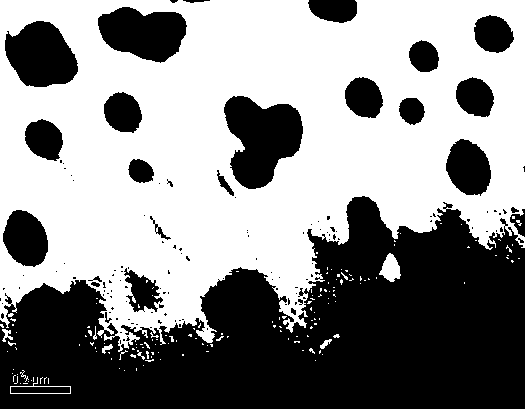

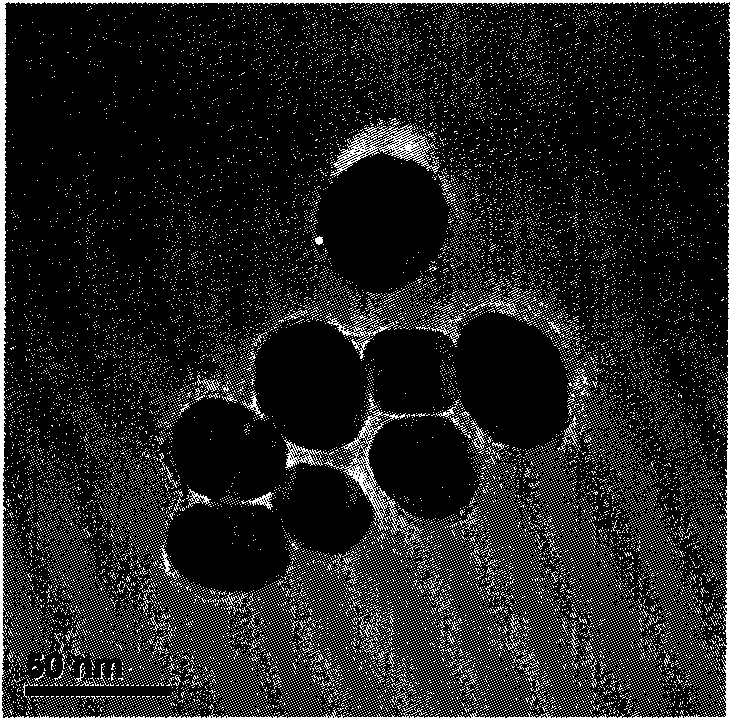

InactiveCN101664557AAdjustable particle sizeTunable LCSTInorganic non-active ingredientsPharmaceutical delivery mechanismGold particlesWater soluble drug

A nano-hydrogel drug carrier material with photosensitivity and temperature sensibility relates to a kind of hydrogel. The invention provides the nano-hydrogel drug carrier material with photosensitivity and temperature sensibility and a preparation method thereof. The nano-hydrogel drug carrier material has core-shell structure, the core is nano-gold core and the shell is poly(N-isopropylacrylamide) shell. The preparation method comprises the following steps: dispersing nano-gold particles in water solution, adding acrylamide to obtain a suspending solution A, standing, centrifuging to collect precipitate, dispersing precipitate in deionized water again to obtain a suspending solution B, adding isopropylacrylamide, N,N'-methylenebisacrylamide, sodium lauryl sulfate and water-soluble drugto obtain a suspending solution C, stirring, adding ammonium persulphate to react and obtain a suspending solution D and finally collecting precipitate to obtain the nano-hydrogel drug carrier material with photosensitivity and temperature sensibility.

Owner:XIAMEN UNIV

Medical dressing hydrogel composite fabric as well as preparation method and application thereof

ActiveCN103736140AHas antibacterial and anti-inflammatory effectsGood biocompatibilityAbsorbent padsBandagesChemistryTraditional Chinese medicine

The invention relates to a medical dressing hydrogel composite fabric as well as a preparation method and an application thereof and belongs to the technical field of a traditional Chinese medicine preparation and a preparation method thereof. The preparation method comprises the following steps: dissolving N-isopropylacrylamide and an initiator by using a solvent and foaming by using nitrogen; carrying out initiation reaction on cotton cellulose in the initiator; soaking the cotton cellulose after the initiation reaction in the mixed solution of N-isopropylacrylamide and dimethylfomamide and then carrying out polymerization reaction in the presence of nitrogen to acquire poly(N-isopropyl acrylamide-cotton cellulose); dissolving poly(N-isopropyl acrylamide-cotton cellulose) together with alginate in distilled water to form hydrosol on the surface, and removing the solvent under low pressure by a rotary evaporator to acquire the medical dressing hydrogel composite fabric. The medical dressing hydrogel composite fabric has the advantages of having high mechanical strength and anti-microbial, anti-infective and hematostatic functions, intelligently controlling humidity to maintain hydrated skin, preventing adhesion of the fabric and cambiums and effectively promoting epithelization and wound healing of tissue cells.

Owner:THE FIFTH MEDICAL CENT OF CHINESE PLA GENERAL HOSPITAL

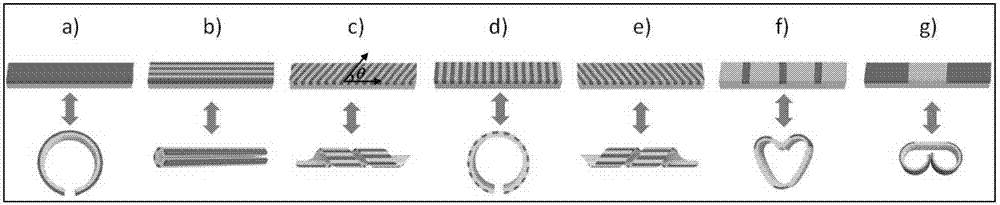

Preparation method of deformation controllable hydrogel actuator

InactiveCN106977649AEasy to controlSimple manufacturing processPharmaceutical non-active ingredientsTissue regenerationHeterojunctionIn situ polymerization

The invention provides a deformation controllable hydrogel actuator and a preparation method thereof. The deformation controllable hydrogel actuator is prepared from an inorganic nano-material, poly(isopropyl acrylamide) and water, wherein the concentration distribution of the inorganic nano-material in a thickness direction is non-uniform, so as to form an asymmetrical heterojunction structure; in a plane direction, the non-uniform asymmetrical structure can be randomly patterned according to requirements, so that various reversible deformation triggered by temperature is realized. The preparation method comprises the following steps: mixing isopropyl acrylamide monomer, an initiator and the inorganic nano-material to form uniform pre-gel; pouring the pre-gel into a rectangular mold; covering one layer of mask plate on the pre-gel; evaporating partial water to induce the concentration of the inorganic nano-material to be not uniformly distributed in the thickness direction of an exposed region; then carrying out in-situ polymerization to fix a patterned non-uniform structure, so as to form the deformation controllable hydrogel actuator. The method is simple and feasible and easy to realize; the deformation controllable hydrogel actuator can be used for soft robots, drug delivery, microfluidic valves and artificial muscle.

Owner:BEIHANG UNIV

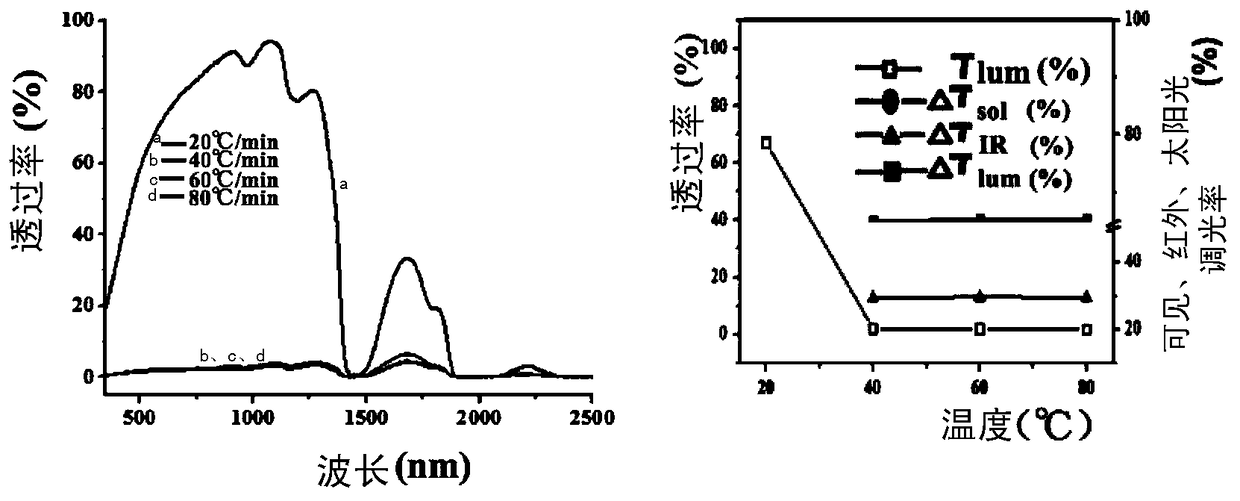

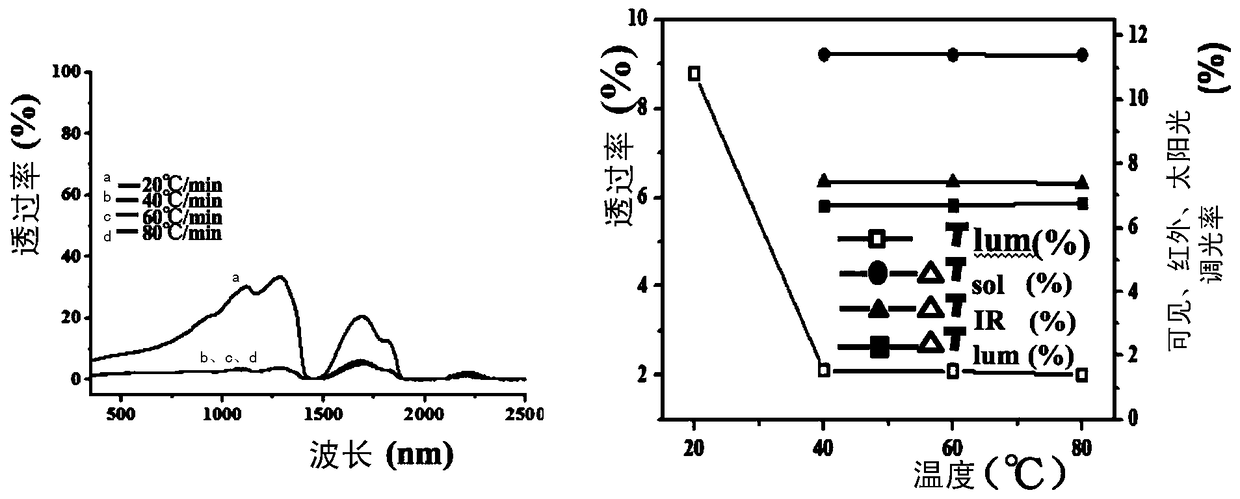

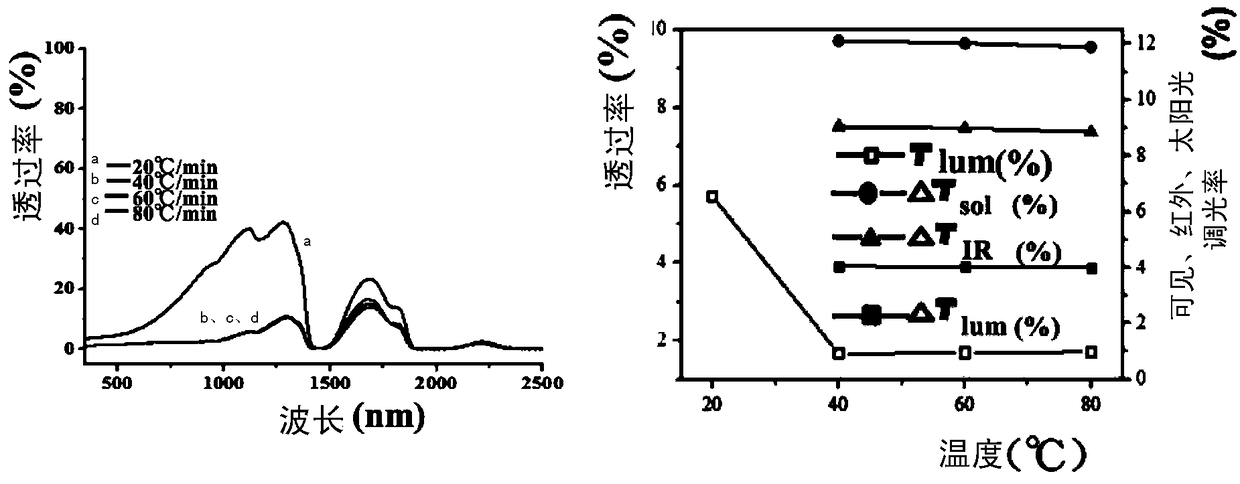

Preparation method of poly(N-isopropylacrylamide) (PNIPAm) microgel and vanadium dioxide/silicon dioxide/PNIPAm composite microgel

Owner:SHANGHAI UNIV

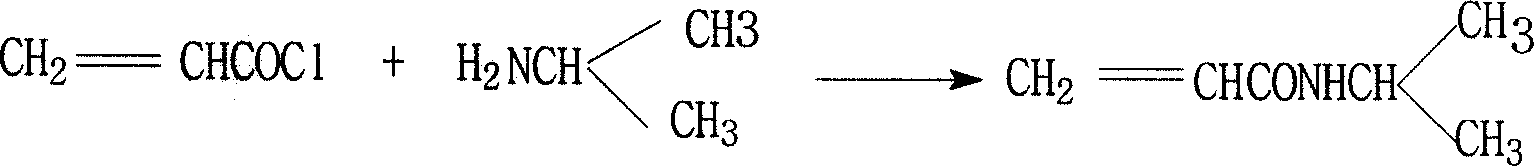

Method for preparing monomer of temperature-sensitive polyisopropylacrylamide

ActiveCN101239927AImprove responseGood for acylationOrganic compound preparationCarboxylic acid amides preparationChemical synthesisStrong acids

The invention belongs to the chemical synthesis technology field, particularly relates to a temperature-sensitive poly(N-isopropylacrylamide) monomer preparing method. The method comprises steps of: (1) respectively adding isopropyl amine and acryloyl chloride into ethyl acetate solvent; (2) adding sollution of acryloyl chloride and ethyl acetate into sollution of isopropyl amine and ethyl acetate to perform synthesis reaction; (3) after the synthesis reaction, filtering to obtain isopropyl amine hydrochloride solution; (4) adding inhibitors; (5) rotating and vaporizing the sollution to remove ethyl acetate solvent, obataining crude products of N-isopropylacrylamide; (6) adding the extraction agent n-hexane, cooling to obtain white crystal N-isopropylacrylamide monomer; (7) vacuum-drying to obain N-isopropylacrylamide monomer products. The invention is free of strong acid, the feeding sequence is simple, the reaction temperature is easy to control, the subsequent separation and purification operation is simple. The invention also has the advantages of small by-products, good selectivety, simple process, high yield and low cost.

Owner:RONGHAI SUPERSONIC MEDICINE EN

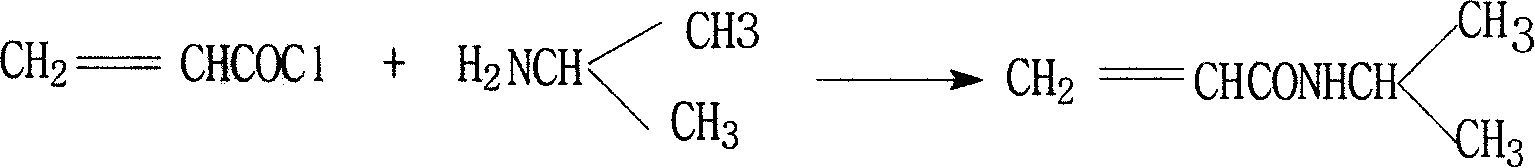

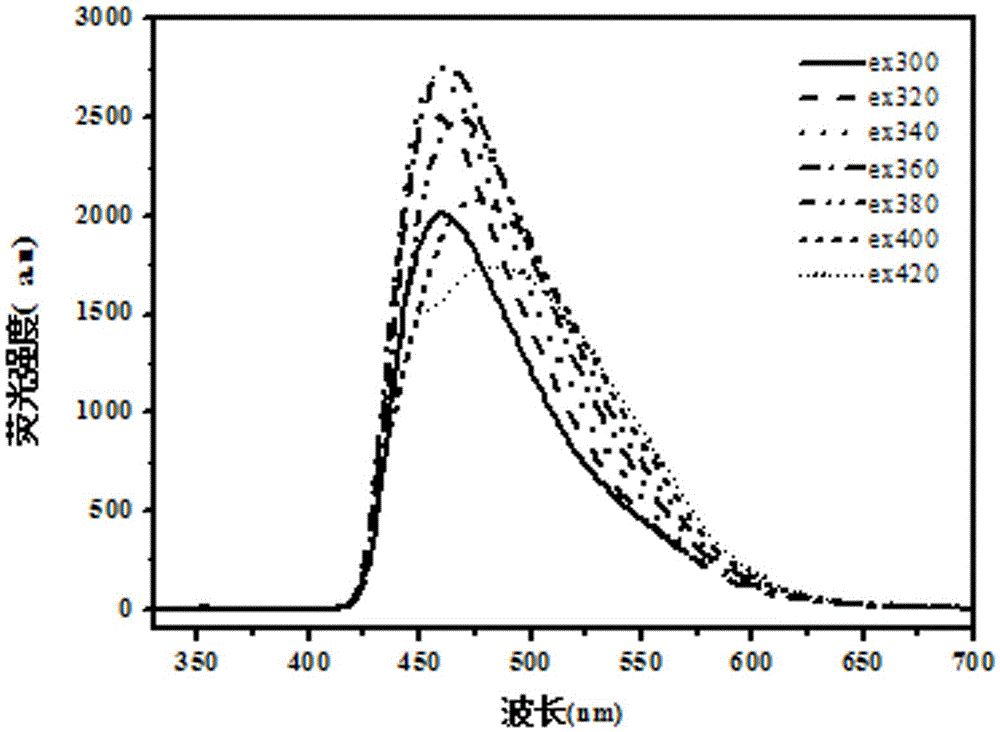

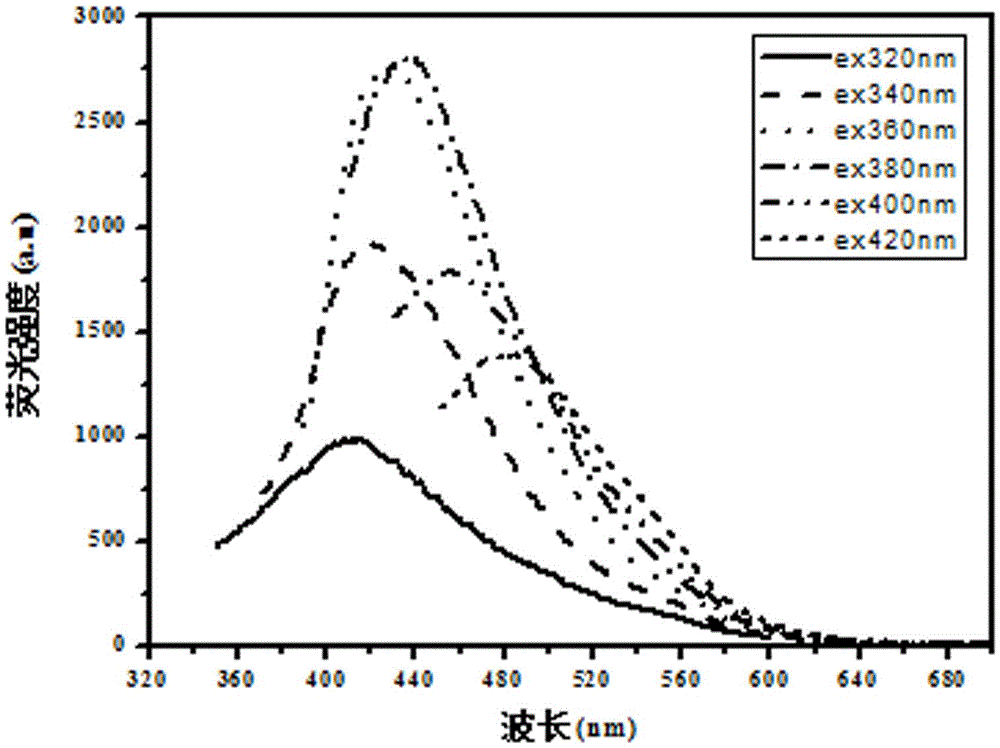

Poly-isopropyl acrylamide functionalized fluorescent silicon quantum dot material and preparation method thereof

ActiveCN105542746AStrong fluorescenceGood fluorescenceLuminescent compositionsFluorescenceQuantum dot

The invention discloses a poly-isopropyl acrylamide functionalized fluorescent silicon quantum dot material. Poly-isopropyl acrylamide is grafted to the surface of fluorescent silicon quantum dot synthesized by a hydrothermal method. The preparation method comprises the following steps: (1) amination of silicon quantum dot; (2) graft of a chain transferring agent on the silicon quantum dot; (3) graft of poly-isopropyl acrylamide by an RAFT polymerization method; and (4) posttreatment to obtain the poly-isopropyl acrylamide functionalized silicon quantum dot with fluorescent responsiveness. The obtained product is non-toxic, and has strong fluorescence, and good prospect in controlled drug delivery, and sensors.

Owner:HUNAN UNIV OF SCI & TECH

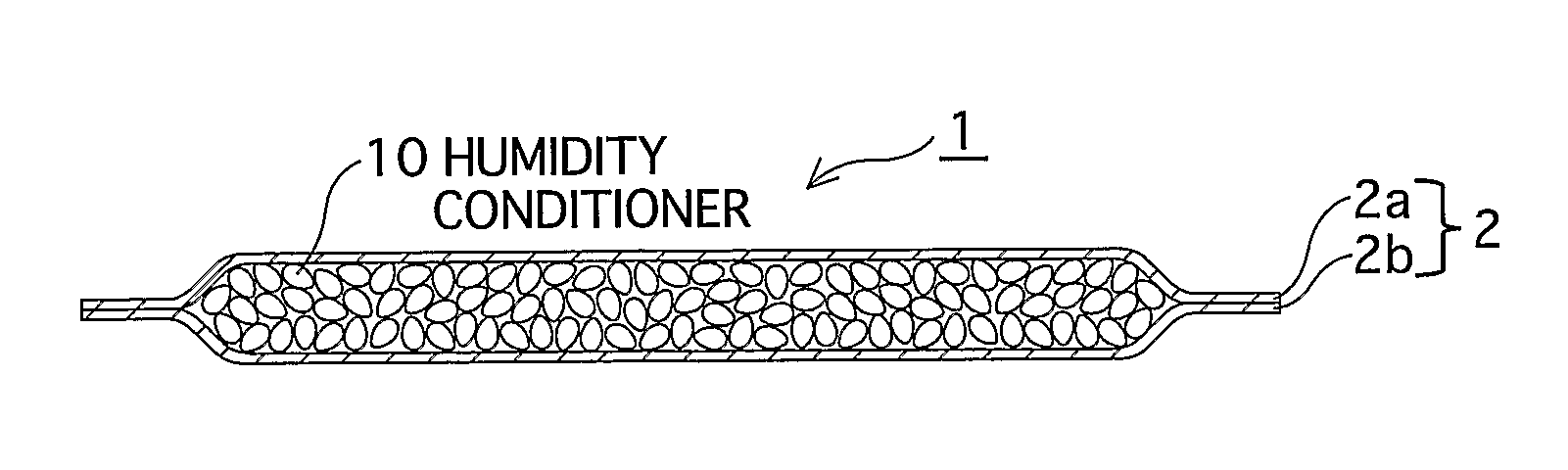

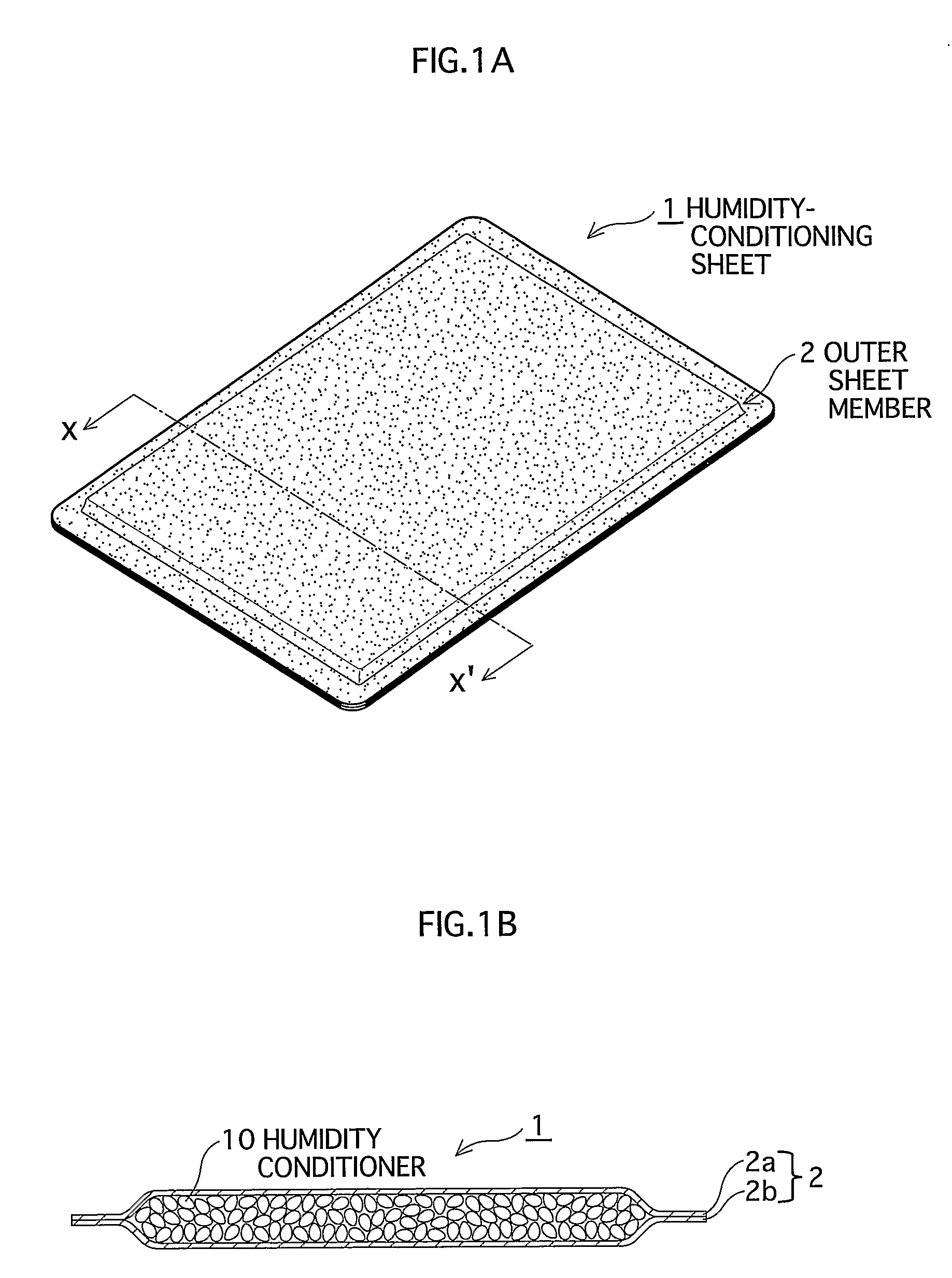

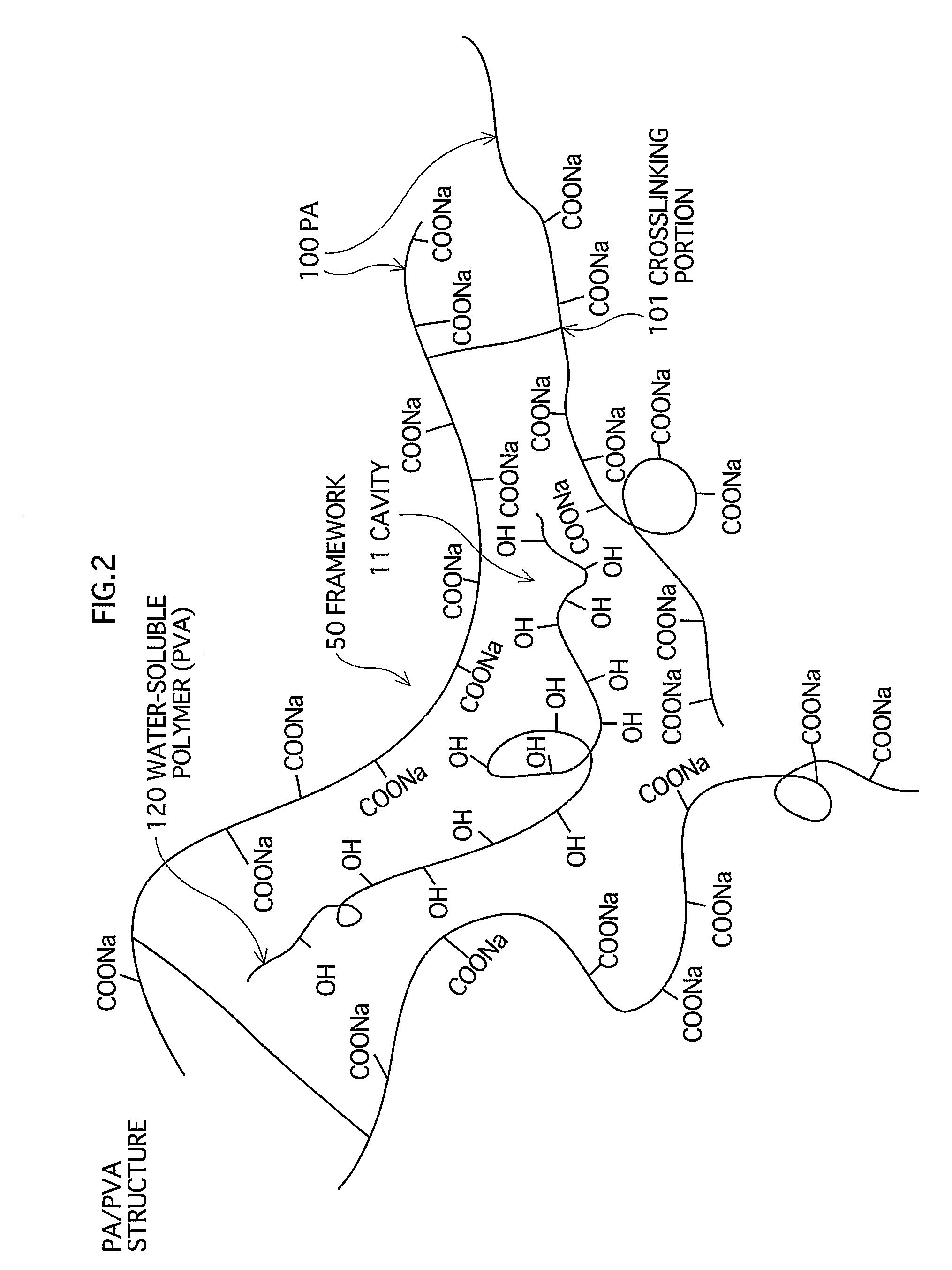

Humidity conditioner and humidity conditioning method using the same

The present invention is a humidity conditioner having a configuration in which one or more water-soluble polymers are introduced into a three-dimensional framework that is formed by one or more crosslinked water-absorbing polymers. Here, for the water-absorbing polymers, either polyacrylate salt or one or more polyacrylate salt-polyvinyl alcohol copolymers can be used. For the water-soluble polymers, one or both of polyvinyl alcohol and polyisopropylacrylamide can be used.

Owner:ABE FUJIO

Temperature and redox stimuli responsive nano-hydrogel and preparation method thereof

The invention discloses temperature and redox stimuli responsive nano-hydrogel and a preparation method thereof. The nano-hydrogel is named as disulfide crosslinking poly(isopropylacrylamide)-grafted glucan. The preparation process comprises the following steps: synthesizing 2-dodecyltrithiocarbonyl-2-methyl propionate; synthesizing 2-dodecyltrithiocarbonyl-2-methyl propionate-grafted glucan macromolecules; synthesizing poly(isopropylacrylamide)-grafted glucan; and synthesizing disulfide crosslinking poly(isopropylacrylamide)-grafted glucan polymer. The nano-hydrogel and preparation method have the following advantages: the preparation method adopts the reversible addition-fragmentation chain transfer free radical polymerization method; the process is characterized in that the polymerization process is controllable, the used reagents are non-toxic or less toxic to the organism, the obtained product molecular structure is accurate and the molecular weight distribution is controllable; and the prepared temperature and redox stimuli responsive nano-hydrogel has wide applicability.

Owner:TIANJIN UNIV

Preparation method of thermosensitive composite gold nanoparticles

The invention discloses a preparation method of thermosensitive composite gold nanoparticles, which comprises the steps of providing an aqueous dispersion of gold nanoparticles, heating to 50-70 DEG C, quickly adding into a thermosensitive polymer solution with an active group which can be combined with gold, and sufficiently mixing for reacting; after the mixed reaction solution is naturally cooled, separating out solid products therein, and cleaning to obtain the thermosensitive composite gold nanoparticles, wherein the gold nanoparticles are preferably the gold nanoparticles with surfaces modified by citric acid radicals, and the thermosensitive polymer with an active group which can be combined with gold is preferably the amino-terminated poly N-isopropylacrylamide (PNIPAM). The preparation method disclosed by the invention has the advantages of mild conditions and short reaction time, is simple and easy to implement, and is environment-friendly; moreover, the obtained product has relatively high yield, relatively good uniformity and good thermosensitivity, and can be widely applied to the fields such as biological optical sensing, medical fluorescence imaging and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

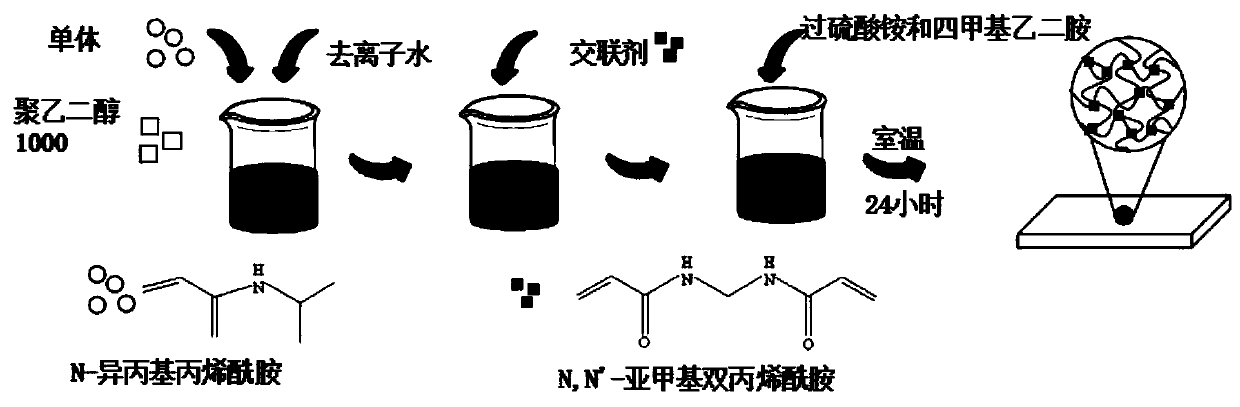

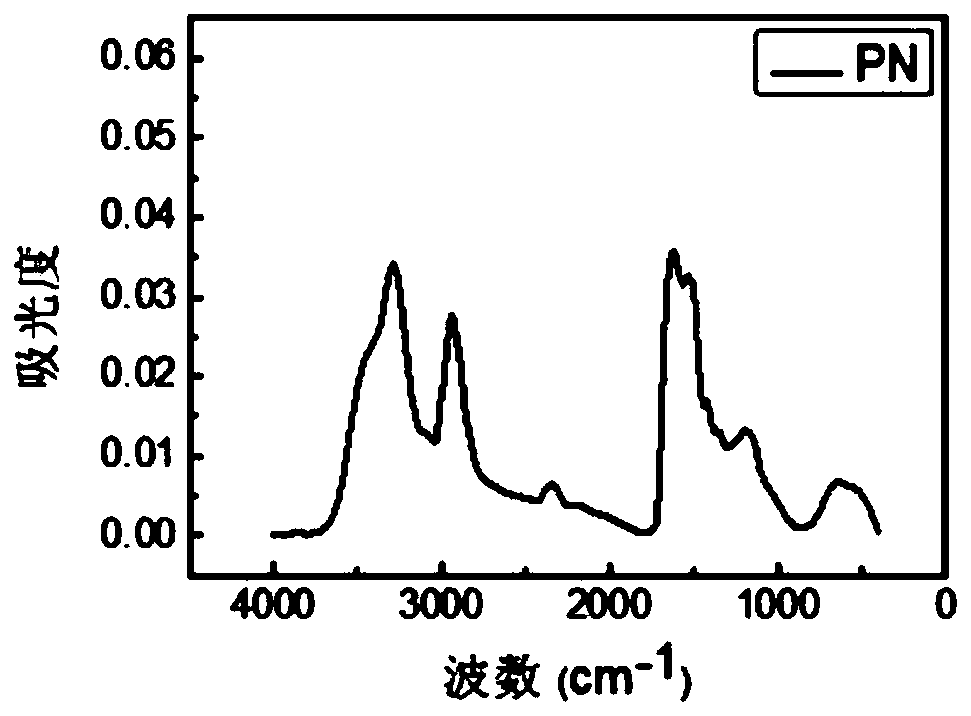

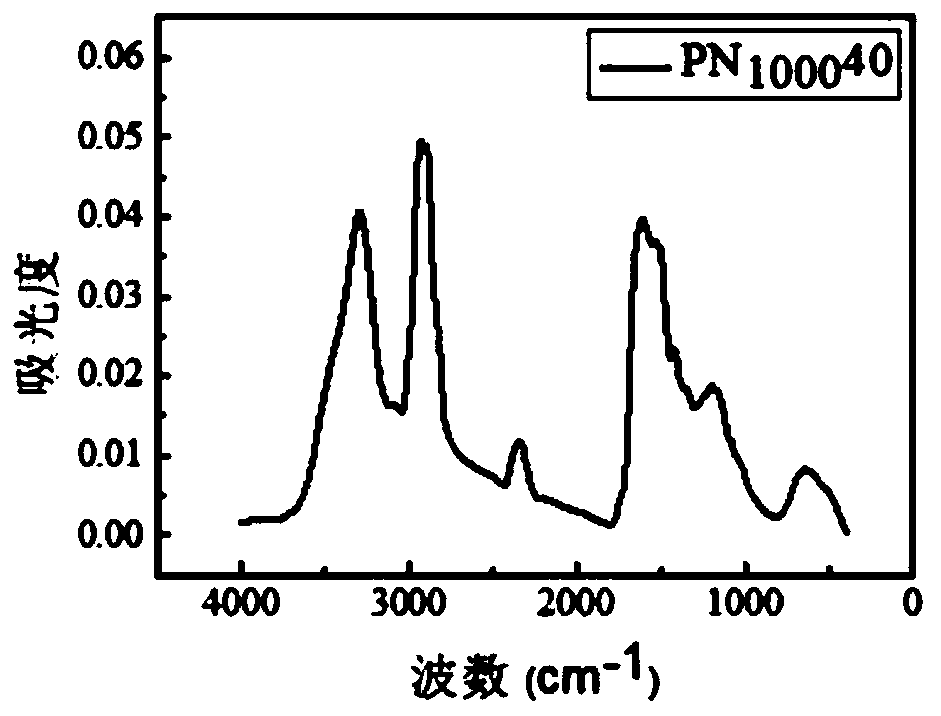

Organic phase change energy storage material and preparation method thereof

ActiveCN111500003ASuitable for fresh storage and transportationImprove thermal conductivityHeat-exchange elementsMeth-Freeze-drying

The invention discloses an organic phase change energy storage material, and also discloses a preparation method of the organic phase change energy storage material. The preparation method comprises the following steps: 1) dissolving N-isopropylacrylamide, N,N'-methylene bisacrylamide and polyethylene glycol 1000 in deionized water together, and initiating a polymerization reaction in a redox system of ammonium persulfate and tetramethylethylenediamine to form poly(N-isopropylacrylamide) gel taking polyethylene glycol 1000 as a pore-foaming agent; 2) soaking in distilled water; 3) putting thefrozen poly(N-isopropylacrylamide) gel into a freeze dryer, and carrying out freeze drying, and 4) respectively soaking the freeze-dried poly(N-isopropylacrylamide) gel into a binary organic compoundfor swelling to obtain the organic phase change energy storage material. The material and the preparation method thereof are very suitable for fresh-keeping storage and transportation of fruits and vegetables.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com