Preparation method for temperature-sensitive chitosan-based polyelectrolyte composite micelle

A technology of chitosan-based polymeric and composite micelles, which is applied in the direction of non-active ingredient medical preparations, pharmaceutical formulas, emulsion delivery, etc., can solve the problems such as the inability to achieve controlled release of drug loading, and achieve controllable loading and release, uniform size distribution, simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

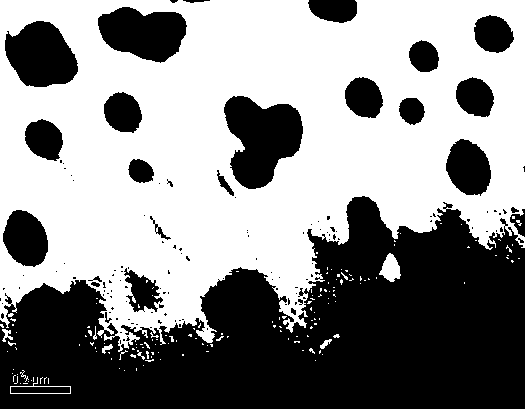

Image

Examples

Embodiment 1

[0018] Dissolve 0.6g of chitosan in 40mL of 5% acetic acid solution. After fully dissolving, add 0.5g of N-isopropylacrylamide, stir and mix well; vacuumize, blow nitrogen, and add the initiator under the protection of nitrogen (0.1 g of ammonium cerium nitrate was dissolved in 10 mL of distilled water), the temperature was raised to 40° C., and the reaction was carried out for 4 hours under constant stirring. The reaction solution was poured into acetone to precipitate, and the crude product was obtained by suction filtration, then extracted with methanol for 24 hours to remove the homopolymer, and dried in a vacuum oven to obtain chitosan-grafted poly-N-isopropylacrylamide copolymer. Sodium carboxymethyl cellulose and chitosan-grafted poly-N-isopropylacrylamide were dissolved in distilled water with a pH value of 5.0 to form a solution with an equal mass concentration of 0.5 mg / mL. Under stirring conditions, Slowly add the graft copolymer solution into the sodium carboxymeth...

Embodiment 2

[0021] Dissolve 0.6g of chitosan in 40mL of 4% acetic acid solution. After fully dissolving, add 1.0g of N-isopropylacrylamide, stir and mix well; vacuumize, blow nitrogen, and add the initiator under the protection of nitrogen (0.1g of potassium persulfate dissolved in 10mL of distilled water), heated up to 60°C, and reacted for 8 hours under constant stirring. Pour the reaction solution into acetone to precipitate, filter with suction to obtain the crude product, then extract with methanol for 36 hours to remove the homopolymer, and dry in a vacuum oven to obtain a copolymer of chitosan grafted poly-N-isopropylacrylamide . Dissolve sodium alginate and chitosan-grafted poly-N-isopropylacrylamide in distilled water with a pH value of 6.0, respectively, to form a solution with a mass concentration of 1 mg / mL. Under stirring conditions, the mass ratio is 3: 7. Slowly add the graft copolymer solution into the sodium alginate solution, and continue stirring for 24 hours to obtain...

Embodiment 3

[0024] Dissolve 0.6g of chitosan in 40mL of 10% acetic acid solution. After fully dissolving, add 2.0g of N-isopropylacrylamide, stir and mix well; vacuumize, blow nitrogen, and add the initiator under the protection of nitrogen (0.1 g of potassium persulfate dissolved in 10 mL of distilled water), heated to 65° C., and reacted for 8 hours under uniform magnetic stirring. Pour the reaction solution into acetone to precipitate, filter with suction to obtain the crude product, then extract with methanol for 48 hours to remove the homopolymer, dry in a vacuum oven to obtain a copolymer of chitosan grafted poly-N-isopropylacrylamide . Sodium alginate and the synthesized graft copolymer were respectively dissolved in distilled water with a pH value of 6.0 to prepare a solution with a mass concentration of 1 mg / mL. Under stirring conditions, the graft copolymer solution was mixed in a mass ratio of 4:6 slowly added into the sodium alginate solution, and continued to stir for 24 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com