Nano-hydrogel drug carrier material with photosensitivity and temperature sensibility

A technology of nano-hydrogel and carrier material, applied in the field of nano-hydrogel drug carrier material, can solve the problems of limited application and single function of pNIPAAm hydrogel, and achieve the effect of controlled release and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

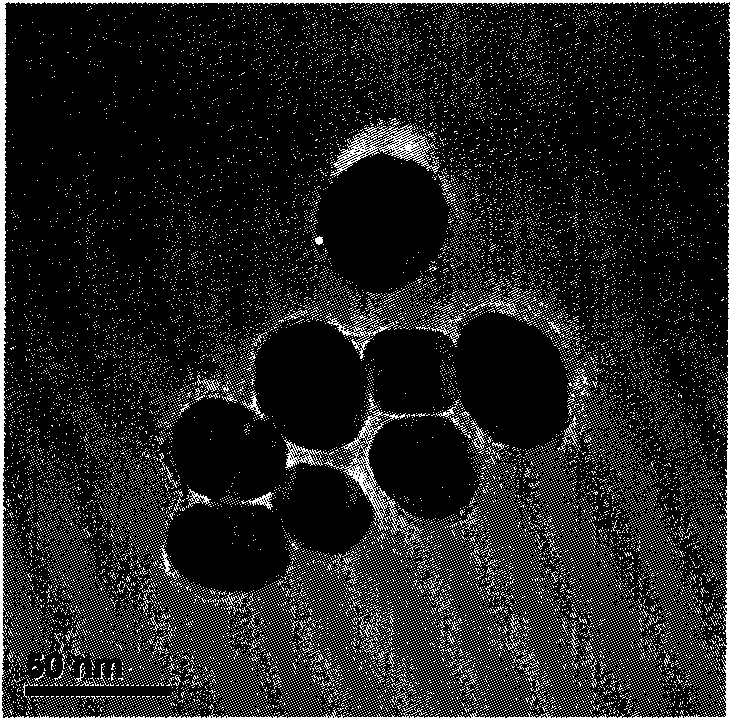

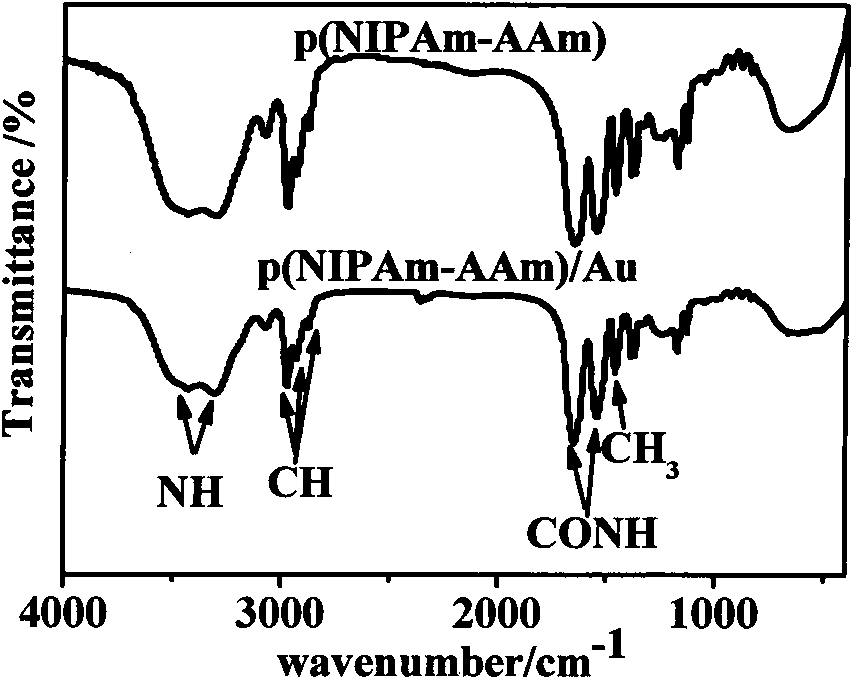

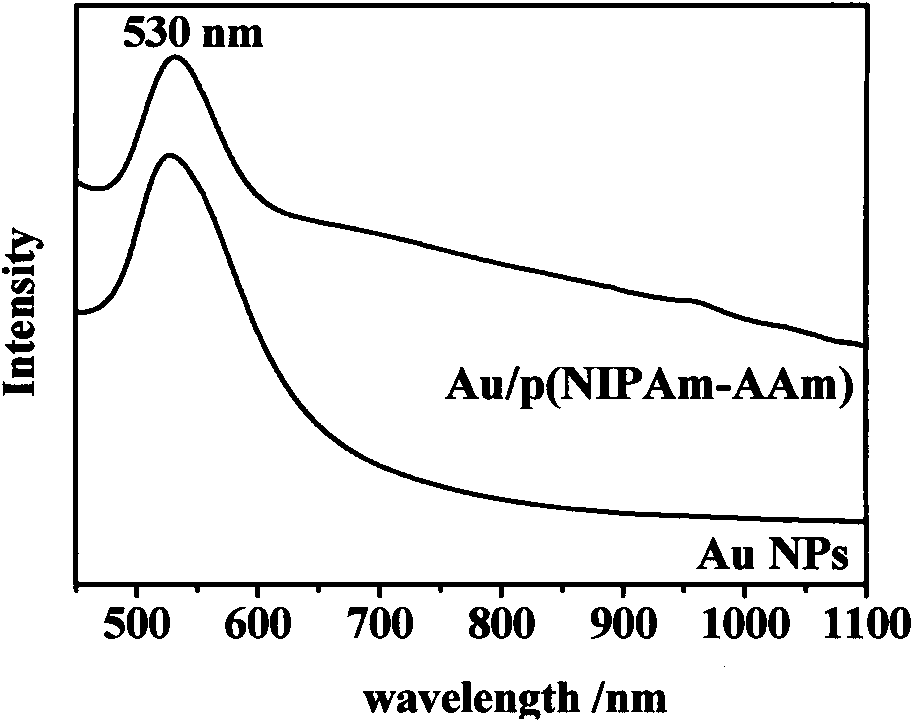

[0039] Will 2.5x10 12 gold nanoparticles / mL (particle size ~50nm) was ultrasonically dispersed in 30mL of deionized water, 0.211mmol of acrylamide was added to the dispersion, and then allowed to stand at 25°C for 12h. After three times of centrifugal washing (11000 rpm, 20 min, 25° C.), the collected precipitate was redispersed in 5 mL of deionized water. Add 1.77mmol of isopropylacrylamide, 12.97μmol of N,N'-methylenebisacrylamide, 86.69μmol of sodium lauryl sulfate and 10mL of deionized water to the above suspension, and stir at 70°C for 1h Then add 109.6μmol ammonium persulfate, and then react at 70°C for 4h. After the reaction, the suspension was centrifuged and washed (11000rpm, 20min, 25°C) 3 times to remove unreacted monomers, and the precipitate was collected to obtain the following: figure 1 The Au / pNIPAAm composite nanohydrogel material with a particle size of 90.47±0.30 nm is shown. The Au / pNIPAAm composite nano hydrogel was lyophilized and characterized by infr...

Embodiment 2

[0041] will be 1.3x10 12 gold nanoparticles / mL (particle size ~15nm) were ultrasonically dispersed in 10 mL of deionized water, 0.211 mmol of acrylamide was added to the dispersion, and then left to stand at 25° C. for 12 h. After three times of centrifugal washing (12000 rpm, 15 min, 20° C.), the collected precipitate was dispersed in 5 mL of deionized water. Add 1.77mmol of isopropylacrylamide, 6.486μmol of N,N'-methylenebisacrylamide, 86.69μmol of sodium dodecyl sulfate and 10mL of deionized water to the above suspension, and stir at 70°C for 1h Then add 131.5μmol ammonium persulfate, and then react at 70°C for 4h. After the reaction, the suspension was centrifuged and washed (9,500-12000rpm, 15min, 25°C) 3 times to remove unreacted monomers, and the precipitate was collected to obtain Au / pNIPAAm composite nanohydra gel with a particle size of 66.28±2.34nm glue material.

Embodiment 3

[0043] Will 8.2x 10 10 gold nanoparticles / mL (particle size ~50nm) was ultrasonically dispersed in 30mL of deionized water, 0.211mmol of acrylamide was added to the dispersion, and then allowed to stand at 25°C for 12h. After three times of centrifugal washing (9,500 rpm, 1525 min, 25° C.), the collected precipitate was dispersed in 5 mL of deionized water. Add 1.77mmol of isopropylacrylamide, 6.486μmol of N,N'-methylenebisacrylamide, 86.69μmol of sodium dodecyl sulfate and 10mL of deionized water to the above suspension, and stir at 70°C for 1h Then add 131.5μmol ammonium persulfate, and then react at 70°C for 4h. After the reaction, the suspension was centrifuged and washed (9,500rpm, 25min, 25°C) 3 times to remove unreacted monomers, and the precipitate was collected to obtain an Au / pNIPAAm composite nano-hydrogel with a particle size of 103.83±1.69nm Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com