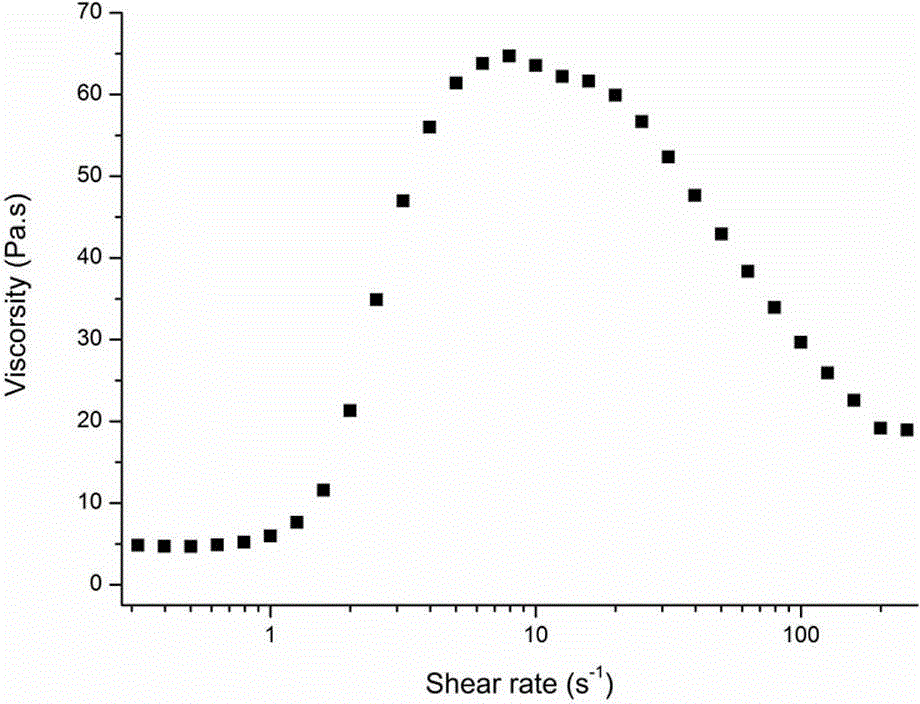

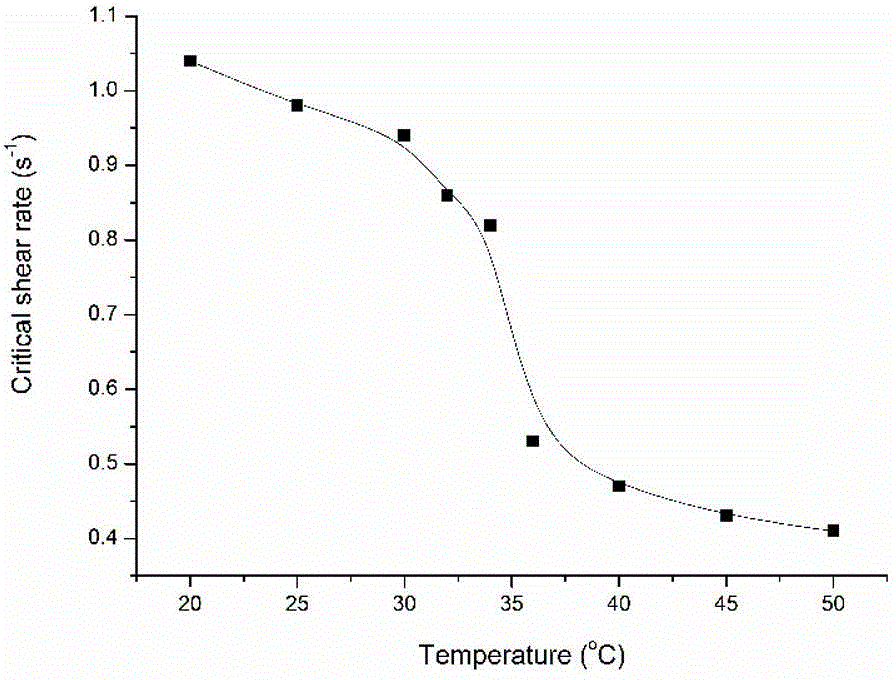

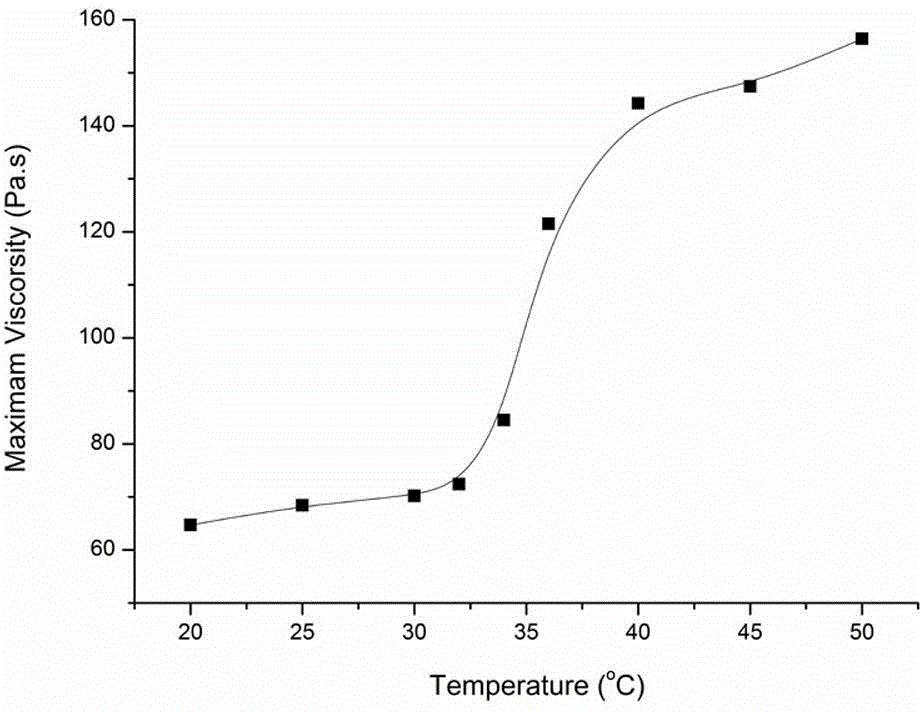

Preparation method of temperature sensitive hydrogel with shear thickening characteristic

A temperature-sensitive hydrogel, characteristic technology, applied in the field of smart hydrogel, can solve the problem of no other control source and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Configuration mass concentration is 115g of the N-isopropylacrylamide aqueous solution of 15%, the grafted nano-SiO that is 20ml with total volume 2 Microspheres were added to it, and ultrasonically oscillated for 20 minutes in an ice-water bath to make the grafted nano-SiO 2 The microspheres were evenly dispersed in it, and 4.5ml of an aqueous solution dissolved with 0.075g of the initiator KPS and 0.14g of the catalyst TEMED was added, and ultrasonic vibration was continued for 20 minutes in an ice-water bath. The above processes were all carried out under nitrogen protection. Afterwards, the reaction vessel was sealed and placed in an ice-water bath to react for 24 hours. After taking it out, soak and change the water repeatedly with deionized water to remove unreacted monomers and solvents to obtain a gel product. Afterwards, a PEG aqueous solution with a concentration of 42% is prepared and injected into the gel through a syringe to obtain a swollen polyethylene g...

Embodiment 2

[0029] Configuration mass concentration is 96g of the N-isopropylacrylamide aqueous solution of 12%, the graft nano-SiO that is 16.8ml with total volume 2 Microspheres were added to it, and ultrasonically oscillated for 20 minutes in an ice-water bath to make the grafted nano-SiO 2 The microspheres were evenly dispersed in it, and 4ml of an aqueous solution dissolved with 0.075g of the initiator KPS and 0.14g of the catalyst TEMED was added, and ultrasonic vibration was continued for 20 minutes in an ice-water bath. The above processes were all carried out under nitrogen protection. Afterwards, the reaction vessel was sealed and placed in an ice-water bath to react for 24 hours. After taking it out, soak and change the water repeatedly with deionized water to remove unreacted monomers and solvents to obtain a gel product. Afterwards, a PEG aqueous solution with a concentration of 35.7% was prepared and injected into the gel through a syringe to obtain a swollen polyethylene g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com