Preparation method of deformation controllable hydrogel actuator

An actuator and hydrogel technology, which is applied in non-active ingredient medical preparations, pharmaceutical formulations, pharmaceutical sciences, etc., can solve the problems of complex preparation methods, poor controllability, and single hydrogel deformation mode, and achieves The preparation process is simple and feasible, and the effect of excellent structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

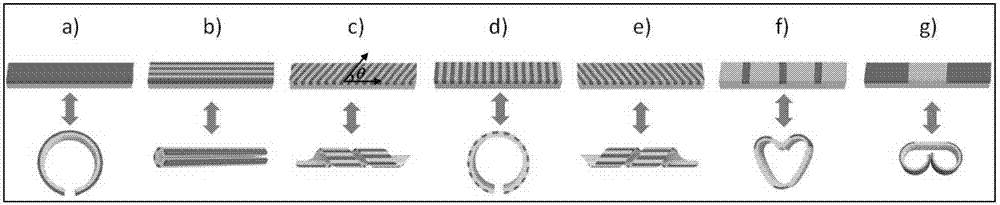

[0028] Example 1: Hydrogel Actuator with Unpatterned Surface Specified Global Bending Deformation

[0029] (1) Disperse the lithium magnesium silicate clay in water by magnetic stirring to form a uniform dispersion.

[0030] (2) Add isopropylacrylamide monomer successively in the dispersion liquid of step (1), stir and dissolve, then add potassium persulfate initiator, stir and dissolve, then add tetramethylethylenediamine catalyst under ice bath, Stir and dissolve to obtain a pregel containing lithium magnesium silicate clay, isopropylacrylamide, potassium persulfate, tetramethylethylenediamine, wherein the concentration of lithium magnesium silicate clay is 4%, and the content of isopropylacrylamide The concentration is 4%, the mass of potassium persulfate is 1% of the mass of isopropylacrylamide, and the mass of tetramethylethylenediamine is 1% of that of isopropylacrylamide.

[0031] (3) Pour the pregel processed in step (2) into a rectangular mold with a thickness of 1 m...

example 2

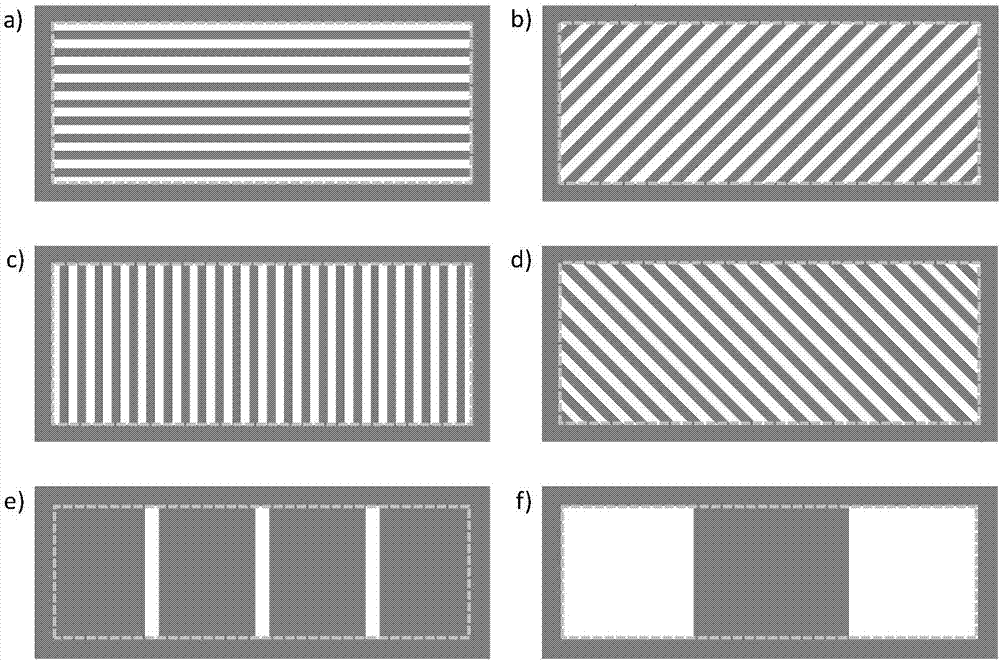

[0034] Example 2: A stripe pattern at a 0° angle to the long side of the hydrogel actuator specifies a hydrogel actuator that bends and deforms along the short side

[0035] (1) Disperse the montmorillonite in water by mechanical stirring to form a uniform dispersion.

[0036] (2) Add isopropylacrylamide monomer successively in the dispersion liquid of step (1), stir and dissolve, then add potassium persulfate initiator, stir and dissolve, then add tetramethylethylenediamine catalyst under ice bath, Stir and dissolve to obtain a uniform pregel containing montmorillonite, isopropylacrylamide, potassium persulfate, and tetramethylethylenediamine, wherein the concentration of montmorillonite is 8%, and the concentration of isopropylacrylamide is 10%. %, the quality of ammonium persulfate is 4% of the quality of isopropylacrylamide, and the quality of tetramethylethylenediamine is 3% of the quality of isopropylacrylamide.

[0037] (3) Pour the pre-gel of step (2) into a 0.5 mm th...

example 3

[0040] Example 3: A stripe pattern at a 45° angle to the long side of the hydrogel actuator specifies a right-handed helical deformation of the hydrogel actuator

[0041] (1) Disperse the layered double hydroxide in water by mechanical stirring to form a uniform dispersion.

[0042] (2) Add isopropylacrylamide monomer successively in the dispersion liquid of step (1), stir and dissolve, then add potassium persulfate initiator, stir and dissolve, then add tetramethylethylenediamine catalyst under ice bath, Stir and dissolve to obtain a uniform pregel containing layered double hydroxide, isopropylacrylamide, potassium persulfate, tetramethylethylenediamine, wherein the concentration of layered double hydroxide is 3%, isopropyl The concentration of acrylamide is 6%, the mass of potassium persulfate is 2.5% of the mass of isopropylacrylamide, and the mass of tetramethylethylenediamine is 2.5% of that of isopropylacrylamide.

[0043] (3) Pour the pregel of step (2) into a rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com