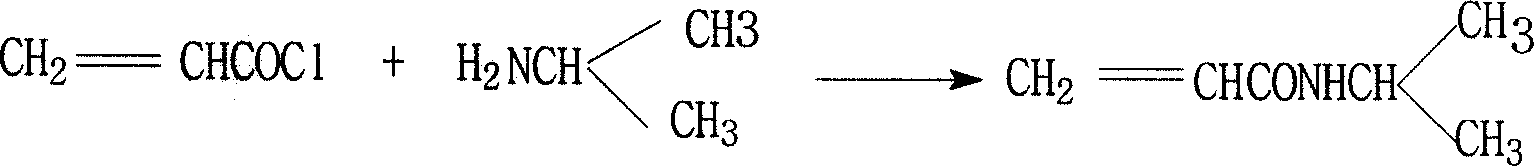

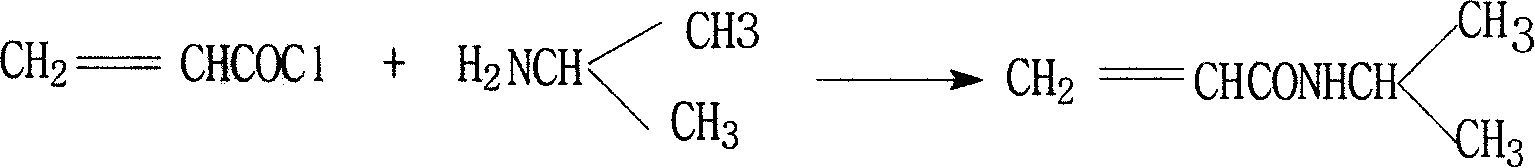

Method for preparing monomer of temperature-sensitive polyisopropylacrylamide

A technology of propylacrylamide and temperature-sensitive type, which is applied in the field of monomer preparation of temperature-sensitive polyisopropylacrylamide, can solve the problems of violent reaction, severe heat release, poor selectivity, etc., and achieve the product with less impurity content, The order of addition is simple and the effect of reducing reaction toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Equipment: 2000ml four-necked bottle (reaction kettle), rotary evaporator, electric heater, water bath, glass thermometer, perforated rubber stopper, vacuum dryer, separating funnel, Erlenmeyer flask;

[0033] Raw materials: ethyl acetate, isopropylamine, acryloyl chloride, 4-methoxyphenol, n-hexane

[0034] step:

[0035] 1) In a 2000ml four-neck bottle, add 950ml ethyl acetate, then add 160g isopropylamine, and add the polymerization inhibitor 4-methoxyphenol, the amount is 0.5g, and cool it to below 5°C with ice water.

[0036] 2) Add 117g of acryloyl chloride diluted with 300ml of ethyl acetate dropwise, and keep the reaction below 5°C.

[0037] 3) After dropping, react for 12 hours, keep the reaction below 5°C, that is, stir in an ice-water bath for 12 hours.

[0038] 4) After the reaction is completed, filter and remove the precipitate to obtain about 1200 ml of isopropylamine hydrochloride solution, and add 0.3 g of polymerization inhibitor 4-methoxyphenol to t...

Embodiment 2

[0043] Equipment and raw materials: 2L four-necked bottle (reaction kettle), rotary evaporator, electric heater, water bath, glass thermometer, perforated rubber stopper, vacuum dryer, separating funnel, Erlenmeyer flask;

[0044] Raw materials: ethyl acetate, isopropylamine, acryloyl chloride, 4-methoxyphenol, n-hexane

[0045] step:

[0046] 1) In a 2L four-neck bottle, add 1000ml of ethyl acetate, then add 80g of isopropylamine, and add 0.2g of polymerization inhibitor 4-methoxyphenol, and cool it to below 5°C with ice water.

[0047] 2) Add 57.5 g of acryloyl chloride diluted with 300 ml of ethyl acetate dropwise, and keep the reaction below 5°C.

[0048] 3) After dripping, react for 12 hours and keep the reaction below 5°C.

[0049] 4) After the reaction is completed, about 1350 ml of isopropylamine hydrochloride solution is obtained by filtration, and 0.1 g of polymerization inhibitor 4-methoxyphenol is added to the solution.

[0050] 5) Ethyl acetate was removed by r...

Embodiment 3

[0054] Equipment: 2L four-necked bottle (reaction kettle), rotary evaporator, electric heater, water bath, glass thermometer, perforated rubber stopper, vacuum dryer, separating funnel, Erlenmeyer flask;

[0055] Raw materials: ethyl acetate, isopropylamine, acryloyl chloride, 4-methoxyphenol, n-hexane

[0056] step:

[0057] 1) In a 2L four-necked bottle, add 1000ml of ethyl acetate, then add 240g of isopropylamine, and add 1.0g of polymerization inhibitor 4-methoxyphenol, and cool it to below 5°C with ice water.

[0058] 2) Add dropwise 175g of acryloyl chloride diluted with 500ml of ethyl acetate, and keep the reaction below 5°C.

[0059] 3) After dripping, react for 12 hours and keep the reaction below 5°C.

[0060] 4) After the reaction is completed, about 1000 ml of isopropylamine hydrochloride solution is obtained by filtration, and 0.5 g of polymerization inhibitor 4-methoxyphenol is added to the solution.

[0061] 5) Ethyl acetate was removed by rotary evaporation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com