Poly-isopropyl acrylamide functionalized fluorescent silicon quantum dot material and preparation method thereof

A technology of propylacrylamide and quantum dot materials, which is applied in the field of optical materials, can solve the problems of narrow application range and poor processability, and achieves the effects of good biocompatibility, good processability and improved application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

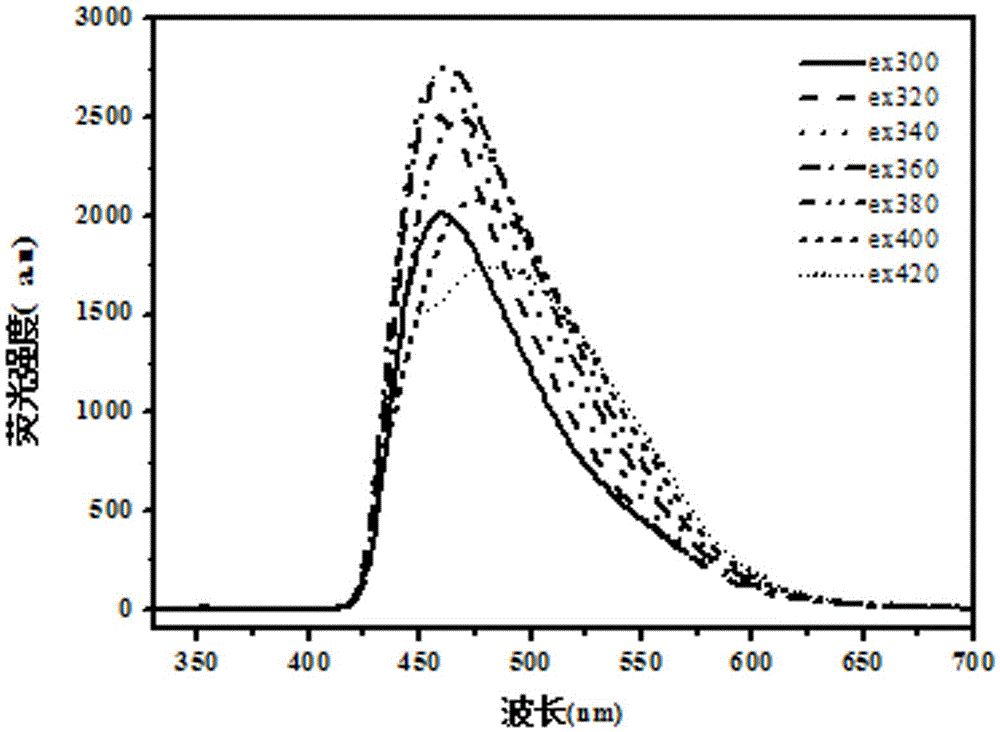

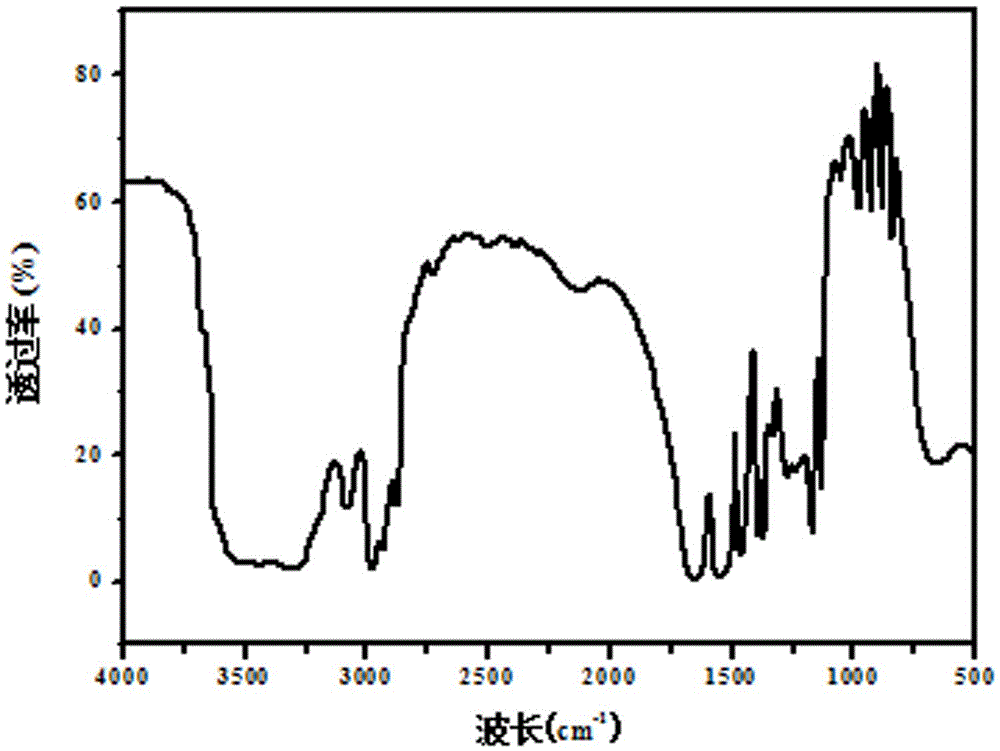

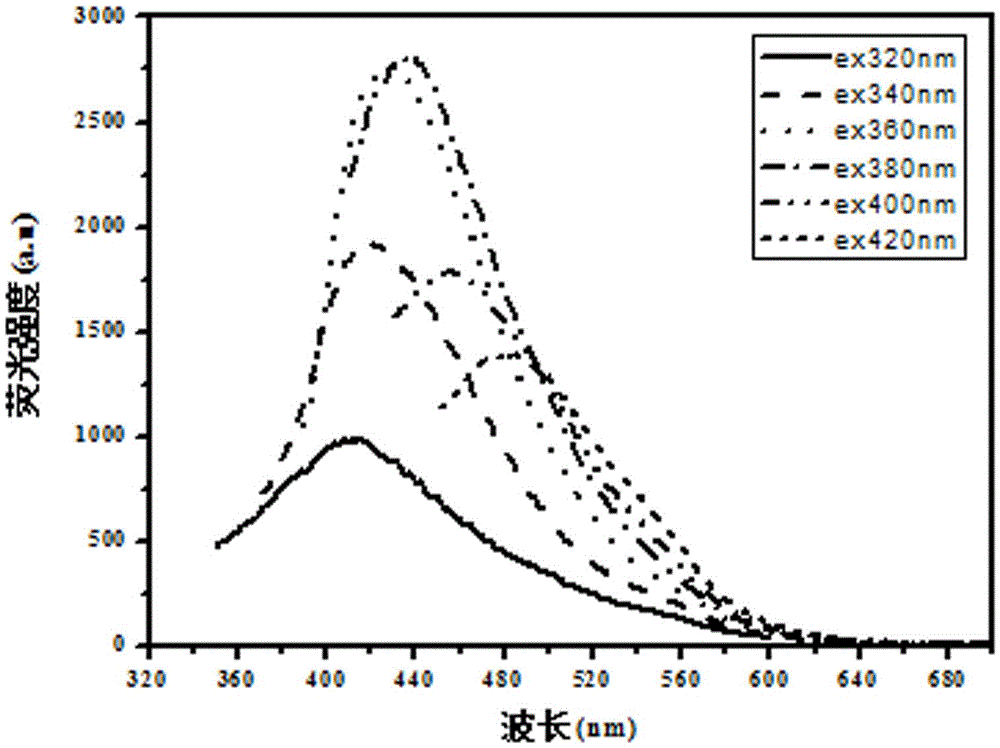

[0029] Weigh 200 mg of fluorescent silicon quantum dots, add them to a mixed solution of 5 mL of ethanol and water, add 1 mL of KH-550 silane coupling agent, stir, react at room temperature for 24 hours, filter to remove the reaction solvent, and then vacuum dry to obtain aminated Fluorescent silicon quantum dots: weigh 50 mg of aminated fluorescent silicon quantum dots, add 10 mL of absolute ethanol to disperse and dissolve them, and transfer them to a round bottom flask, add 20 mg of EDC, 30 mg of NHS, and 30 mg of trithiocarbonate. Continue to stir, react at room temperature for 24 hours, and then dialyze in ethanol for 48 hours. The resulting solution is a purified fluorescent silicon quantum dot chain transfer agent; take 400 μL fluorescent silicon quantum dot chain transfer agent in a 10 mL ampoule, add 80 μL AIBN, 200 mg refined N-isopropylacrylamide, vacuumize after freezing under liquid nitrogen, then pass through nitrogen, repeat the operation of freezing-vacuumizing-...

Embodiment 2

[0031] Weigh 200 mg of fluorescent silicon quantum dots, add them to a mixed solution of 5 mL of ethanol and water, add 1 mL of KH-550 silane coupling agent, stir, react at room temperature for 24 hours, filter to remove the reaction solvent, and then vacuum dry to obtain aminated Fluorescent silicon quantum dots, weigh 50 mg of aminated fluorescent silicon quantum dots, add 10 mL of absolute ethanol to disperse and dissolve, and transfer it to a round bottom flask; add 20 mg EDC, 30 mg NHS, and 30 mg trithiocarbonate. Continue to stir, react at room temperature for 24 hours, and then dialyze in ethanol for 48 hours. The resulting solution is a purified fluorescent silicon quantum dot chain transfer agent. Take 400 μL fluorescent silicon quantum dot chain transfer agent in a 10 mL ampoule, add 80 μL AIBN, 200 mg refined N-isopropylacrylamide, vacuumize after freezing under liquid nitrogen, then pass through nitrogen, repeat the operation of freezing-vacuumizing-nitrogen for 5 t...

Embodiment 3

[0033] Weigh 200 mg of fluorescent silicon quantum dots, add them to a mixed solution of 5 mL of ethanol and water, add 1 mL of KH-550 silane coupling agent, stir, react at room temperature for 24 hours, filter to remove the reaction solvent, and then vacuum dry to obtain aminated Fluorescent silicon quantum dots, weigh 50 mg of aminated fluorescent silicon quantum dots, add 10 mL of absolute ethanol to disperse and dissolve, and transfer it to a round bottom flask; add 20 mg EDC, 30 mg NHS, and 30 mg trithiocarbonate. Continue to stir, react at room temperature for 24 hours, and then dialyze in ethanol for 48 hours. The resulting solution is a purified fluorescent silicon quantum dot chain transfer agent. Take 400 μL fluorescent silicon quantum dot chain transfer agent in a 10 mL ampoule, add 80 μL AIBN, 400 mg refined N-isopropylacrylamide, vacuumize after freezing under liquid nitrogen, then pass through nitrogen, repeat the operation of freezing-vacuumizing-nitrogen for 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com