Production method for CdS and CdS/ZnS core-shell type quantum point

A quantum dot and core-shell type technology, which is applied in the field of preparation of CdS and CdS/ZnS core-shell type quantum dots, can solve the problem of low luminous efficiency of CdS quantum dots, unsatisfactory performance of binary quantum dots, poor fluorescence performance and stability and other problems, to achieve the effect of low preparation cost, strong fluorescence performance and stability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

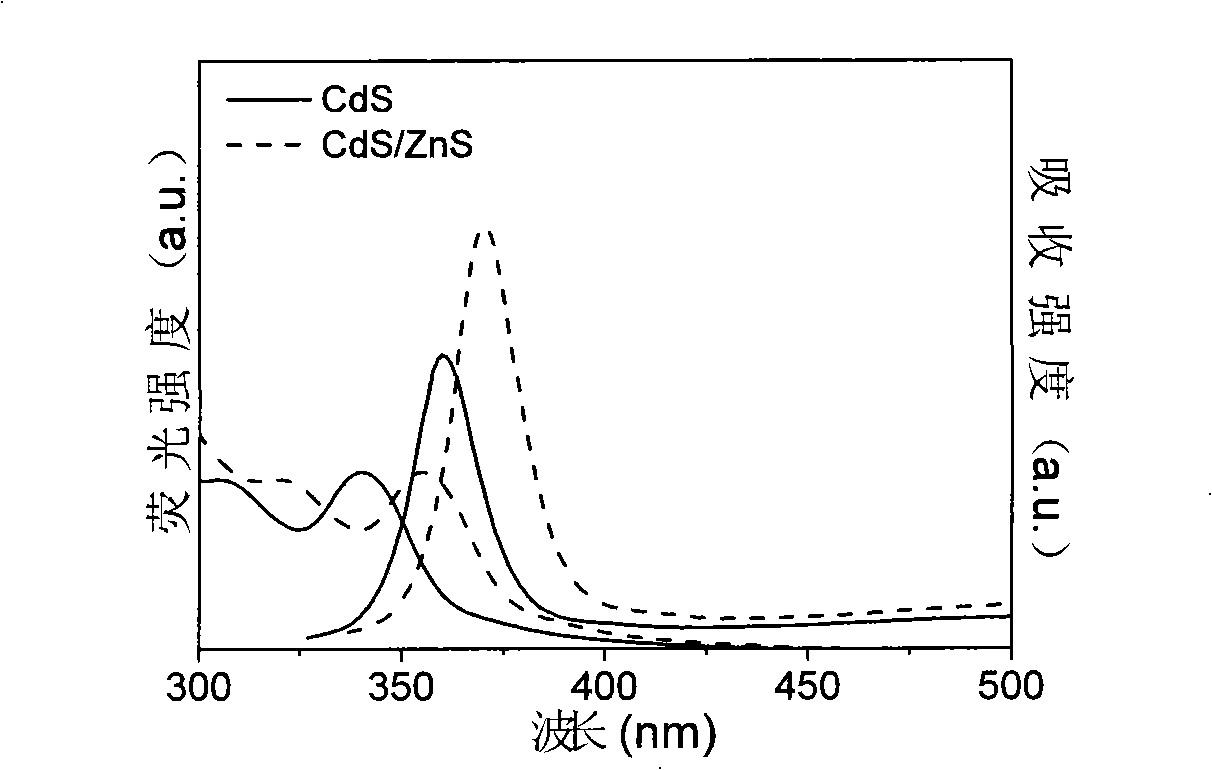

Embodiment 1

[0030] (a) Preparation of CdS quantum dot solution

[0031] Measure 0.16mL of oleic acid and 9.8mL of liquid paraffin, mix them in a three-neck bottle A, heat to 150°C, add 0.0642g of cadmium oxide powder, make the molar ratio of Cd to oleic acid 1:1, wait until the cadmium oxide powder is completely After dissolving, a Cd precursor solution with a concentration of 50 mmol / L was obtained; measure 20 mL of liquid paraffin and place it in a three-necked bottle B, add 0.0032 g of sulfur powder, and make the sulfur powder in the Completely dissolve in liquid paraffin to obtain a S precursor solution with a concentration of 5 mmol / L; heat the S precursor solution to 180°C, extract 4mL of the Cd precursor solution, and quickly inject it into the high temperature solution of the S precursor, accompanied by strong Stir mechanically, and after reacting for 1 minute, the solution is rapidly cooled to room temperature to obtain a CdS quantum dot solution.

[0032] (b) Preparation of ZnS...

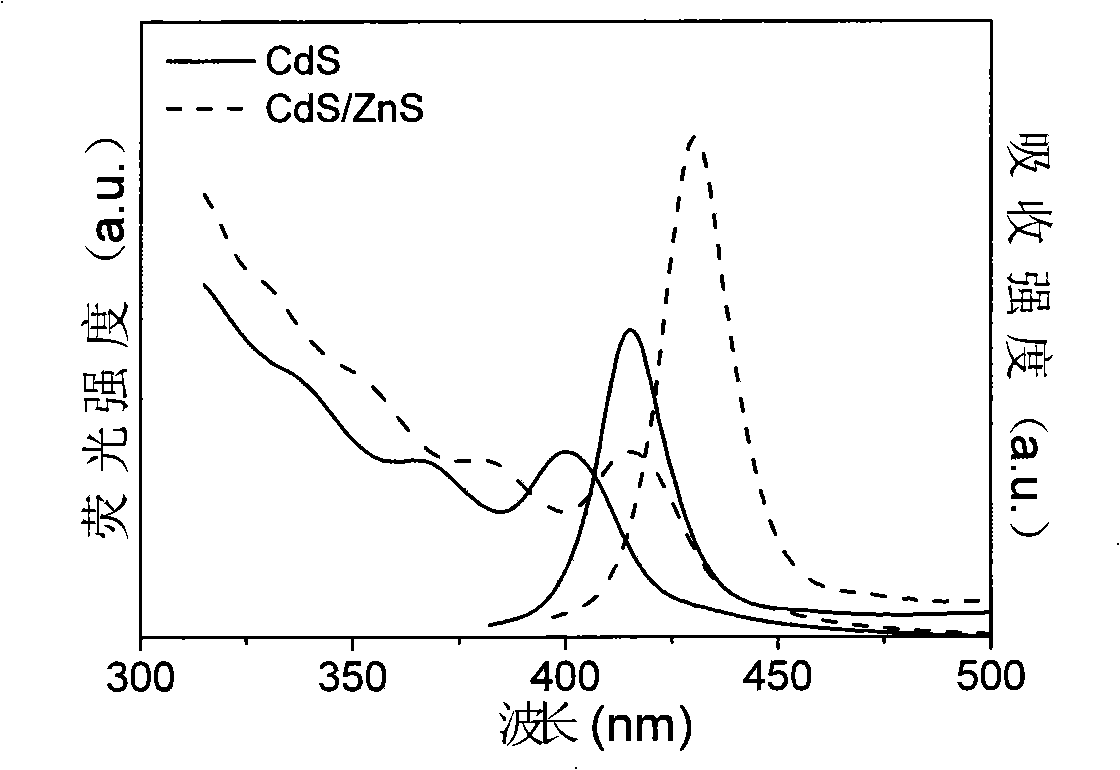

Embodiment 2

[0039] (a) Preparation of CdS quantum dot solution

[0040] Measure 1.7068g of stearic acid and 8mL of liquid paraffin and mix them in a three-neck bottle A, heat to 150°C, add 1.3568g of cadmium stearate powder to make the molar ratio of Cd to stearic acid 1:3, wait until hard After the cadmium fatty acid powder is completely dissolved, a Cd precursor solution with a concentration of 50 mmol / L is obtained; measure 20 mL of liquid paraffin and place it in the three-necked bottle B, add 0.0128 g of sulfur powder, and place it at 120 ° C under the condition of rapid mechanical stirring The sulfur powder was completely dissolved in liquid paraffin to obtain a S precursor solution with a concentration of 20 mmol / L; the S precursor solution was heated to 200°C, 4mL of the Cd precursor solution was extracted, and quickly injected into the S precursor high-temperature solution , accompanied by strong mechanical stirring, after 15 minutes of reaction, the solution was rapidly cooled t...

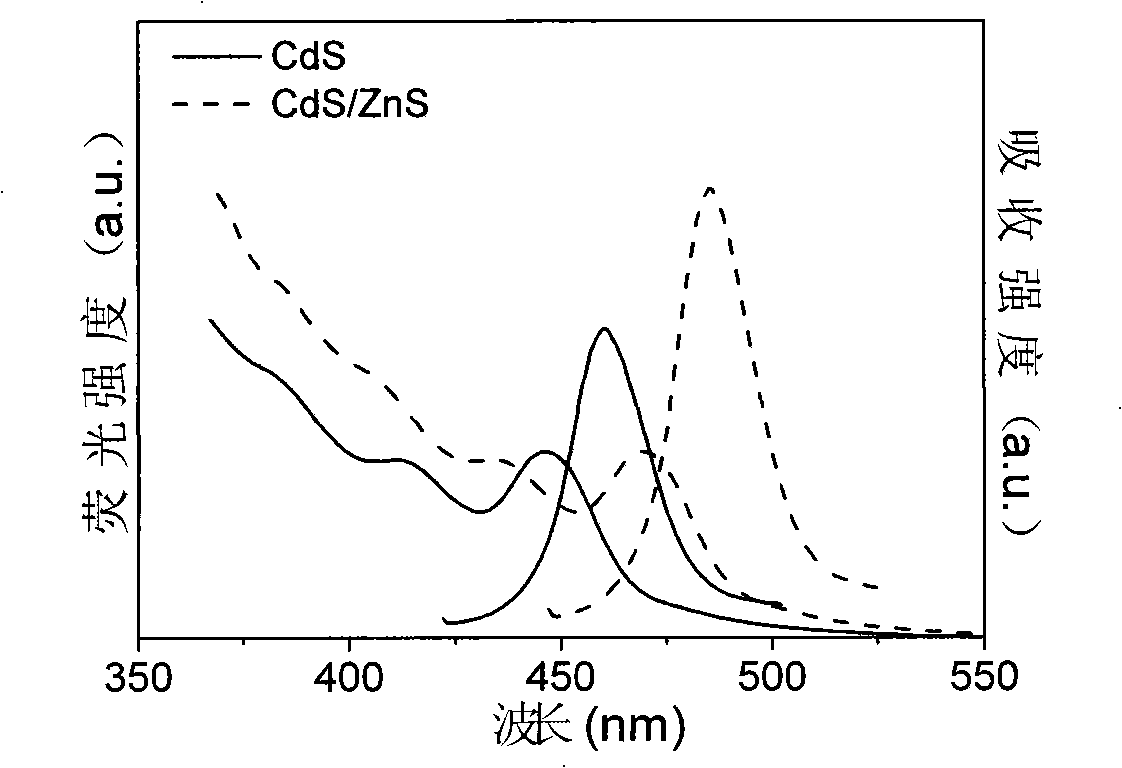

Embodiment 3

[0048] (a) Preparation of CdS quantum dot solution

[0049] Weigh 5.13g of palmitic acid and 5mL of liquid paraffin, mix them in a three-neck bottle A, heat to 150°C, add 1.0187g of cadmium oxalate powder, so that the molar ratio of Cd to palmitic acid is 1:5, and the cadmium oxalate powder After complete dissolution, a Cd precursor solution with a concentration of 400 mmol / L was obtained; measure 20 mL of liquid paraffin and place it in a three-necked bottle B, add 0.0256 g of sulfur powder, and make the sulfur powder under the condition of rapid mechanical stirring at 120 ° C. Completely dissolve in liquid paraffin to obtain a S precursor solution with a concentration of 40 mmol / L; heat the S precursor solution to 240°C, extract 4mL of the Cd precursor solution, and quickly inject it into the high temperature solution of the S precursor, accompanied by Stir vigorously, react for 30 minutes, and quickly cool the solution to room temperature to obtain a CdS quantum dot solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com