Temperature sensitive composite gold nano particles and preparation method and catalytic application thereof

A nanoparticle and composite gold technology, which is applied in the field of gold nanomaterials, can solve problems such as easy coagulation, poor stability, and poor temperature sensitivity, and achieve good temperature sensitivity, good stability, and simple, convenient and fast preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Synthesis of polyisopropylacrylamide grafted dextran polymer (DexPNI):

[0023] Add 12mL of dodecanethiol, 40mL of acetone and 0.8mL of trioctylmethylammonium chloride into a 150mL three-necked flask, under N 2 Under protection, cool to 10°C. Add 4 mL of 50% sodium hydroxide solution dropwise within 20 minutes, and stir for 15 minutes after the dropwise addition. A mixed solution of 3mL carbon disulfide and 8mL acetone was added dropwise, at this time the solution gradually turned red, and the reaction was continued for 30min with stirring. After that, 13 mL of 50% sodium hydroxide was added dropwise, and stirred at room temperature for 12 h. Add 65mL of water and acidify with 33mL of concentrated hydrochloric acid to finally obtain a yellow solid. The yellow solid was recrystallized eight times with n-hexane, and the obtained yellow crystal was 2-dodecyltrithiocarbonyl-2-methylpropionic acid (DTM). in N 2 Under protection, 0.55 g of DTM was dissolved in 5 mL o...

Embodiment 2

[0030] Step (1) of this embodiment is the same as step (1) of Embodiment 1.

[0031] (2) Synthesis of temperature-sensitive composite gold nanoparticles:

[0032] Polymer (DexPNI) solution (1mL, 10mg / mL) and chloroauric acid (HAuCl 4 ) (1mL, 10mmol / L) mixed, then add excess sodium borohydride (NaBH 4 ) (5mL, 10mmol / mL), shake until the reaction color does not change (about 1min), and gold nanoparticles are formed.

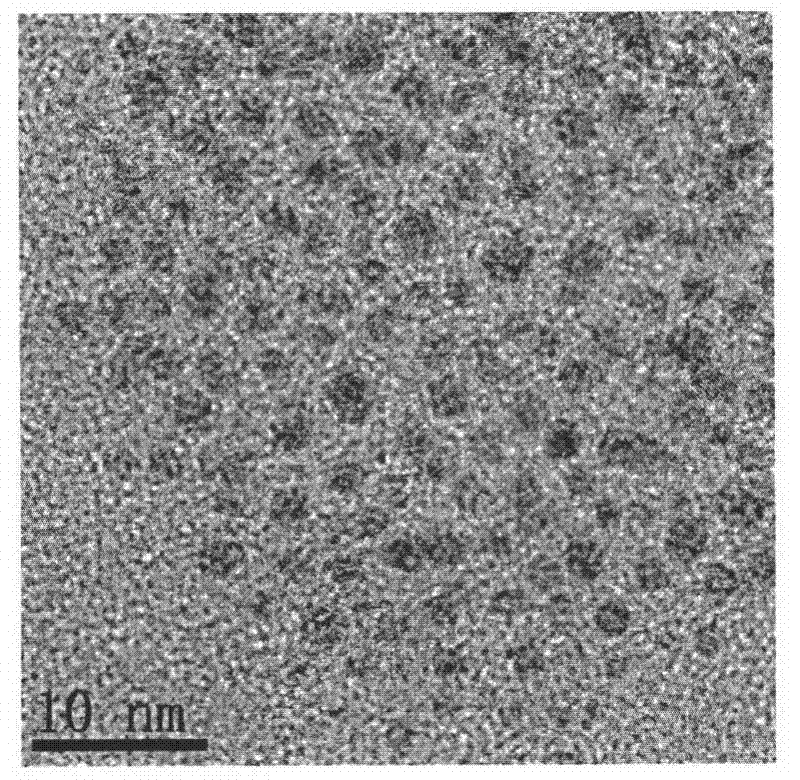

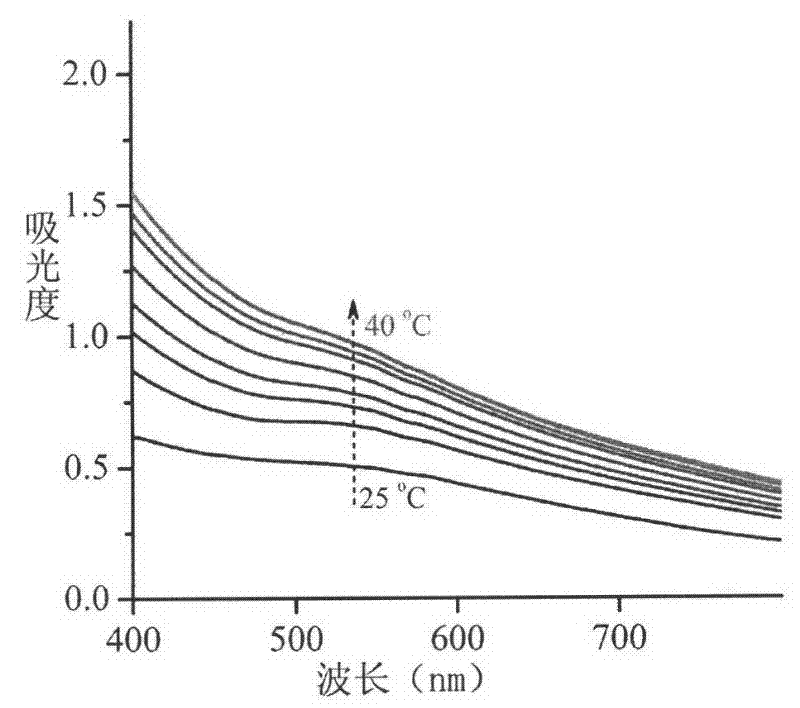

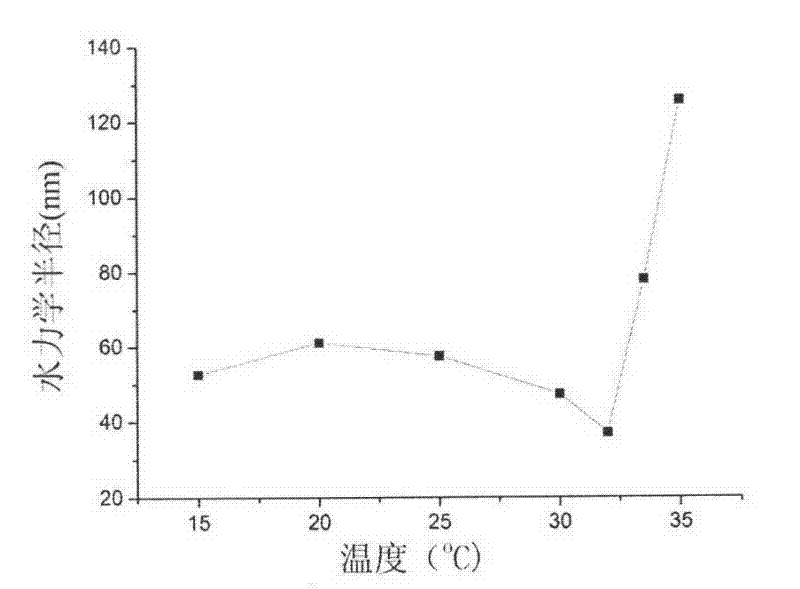

[0033]The colloidal solution of gold nanoparticles is brown, and the transmission electron microscope analysis of the product shows that its particle size is about 3.4±0.9nm, it is spherical, and there is no obvious agglomeration phenomenon. It is a characteristic peak of gold nanoparticles with a particle size greater than 3nm. When the temperature rises to 40°C, the absorbance increases significantly, and the peak red shifts to 526nm.

Embodiment 3

[0035] Step (1) of this embodiment is the same as step (1) of Embodiment 1.

[0036] (2) Synthesis of temperature-sensitive composite gold nanoparticles:

[0037] Polymer (DexPNI) solution (1mL, 10mg / mL) and chloroauric acid (HAuCl 4 ) (2mL, 10mmol / L) mixed, then add excess sodium borohydride (NaBH 4 ) (10mL, 10mmol / mL), shake until the reaction color does not change (about 1min), and gold nanoparticles are formed.

[0038] The gold nanoparticle colloidal solution is red, and the transmission electron microscope analysis of the product shows that its particle size is about 10±1nm, and its shape is circular, triangular and polygonal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com