Polyurethane-rock wool insulating and fireproof material and preparation method thereof

A thermal insulation and fireproof material, polyurethane technology, applied in the field of thermal insulation, can solve the problems of weak material deformation ability, poor waterproof, difficult construction, etc., to achieve the effect of reducing production cost, increasing production speed and good working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

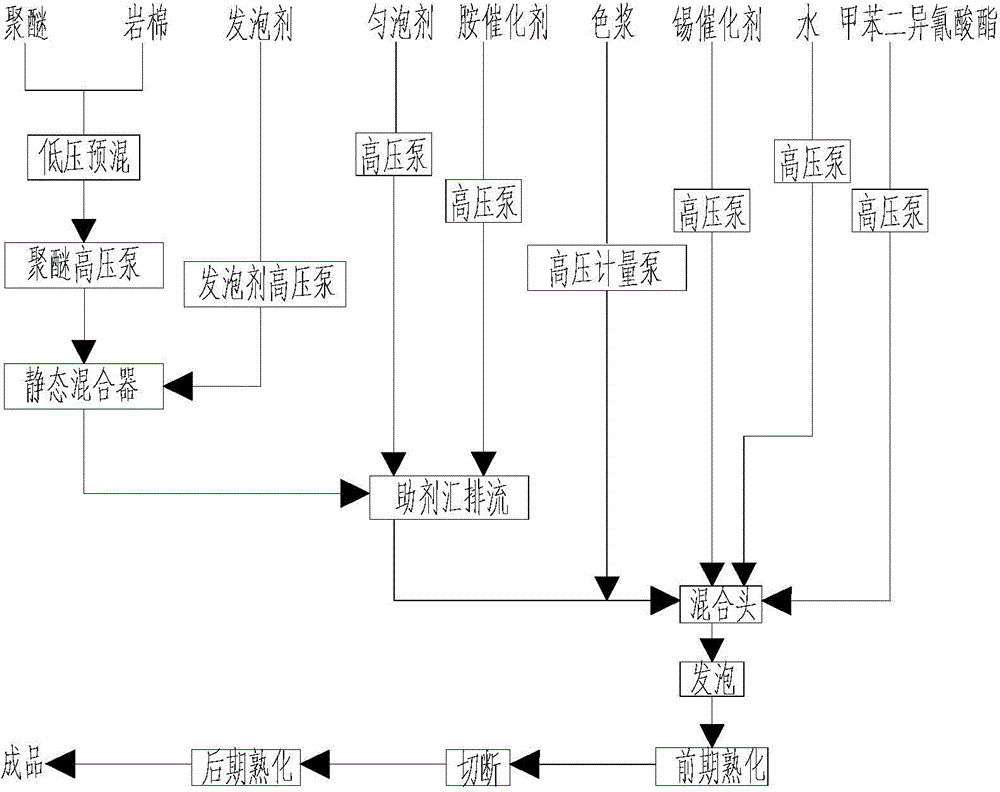

[0043] Embodiment 1 The preparation method (production process) of polyurethane-rock wool thermal insulation and fireproof material of the present invention

[0044] include:

[0045] (1) First use a grinder to grind rock wool into powder, and the particle size of rock wool is less than 0.6mm;

[0046] (2) 100 parts by mass of polyether mixture and rock wool powder (20-30 parts by mass) of the aforementioned particle size were premixed at 0.40 MPa for more than 30 minutes under low pressure, and the materials were fully and uniformly mixed, and pressurized to 3.0 by a pressure pump ~4.0MPa high pressure state.

Embodiment 2

[0047] Embodiment 2 The preparation method (production process) of polyurethane-rock wool thermal insulation and fireproof material of the present invention

[0048] On the basis of embodiment 1, further include:

[0049](3) Pressurize 2 to 4 parts by mass of foaming agent to a high pressure of 3.0 to 4.0 MPa through a high pressure pump, and directly mix the mixture of foaming agent, polyether and rock wool under a high pressure of 3.0 to 4.0 MPa in a static state premixed in the tank and sent to the auxiliary sink stream.

Embodiment 3

[0050] Embodiment 3 The preparation method (production process) of polyurethane-rock wool thermal insulation and fireproof material of the present invention

[0051] On the basis of embodiment 1 and 2 further comprise:

[0052] (4), other components such as foam stabilizer (1.5-2.2 parts by mass), amine catalyst (0.55-0.58 parts by mass), color paste (0.2 parts by mass), tin catalyst (0.27-0.30 parts by mass), toluene Diisocyanate (48 parts by mass) and the like are also under a high pressure of 3.0-4.0 MPa, and the materials are sent to the auxiliary agent confluence flow through each high-pressure pump.

[0053] The components then enter the mixing head, where they are mechanically foamed. Or before the components enter the mixing head, the components are fully mixed and transported to the pouring device through the conduit. When reaching the pouring device, the pressure drops to 1.5-2.5MPa. The state flows evenly on the base film for foaming.

[0054] (5) The materials p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com