Linear driving oil pumping unit

A technology of linear drive and pumping unit, which is applied in the direction of electromechanical devices, electric components, and control of mechanical energy. It can solve problems such as increased operating costs, failure to reach, and fatigue of pipes and rods, and achieves low transportation and installation costs, and is easy to transport and install. Power Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

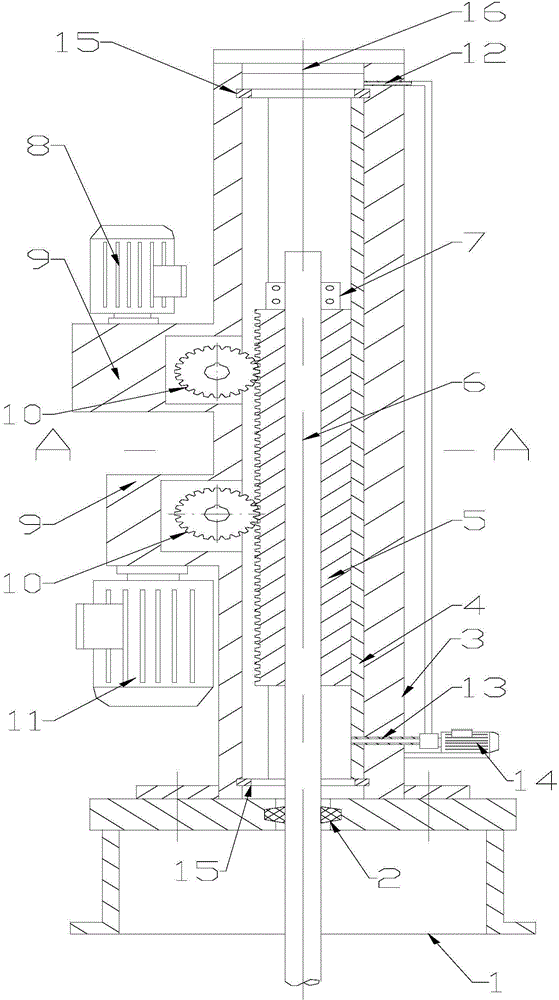

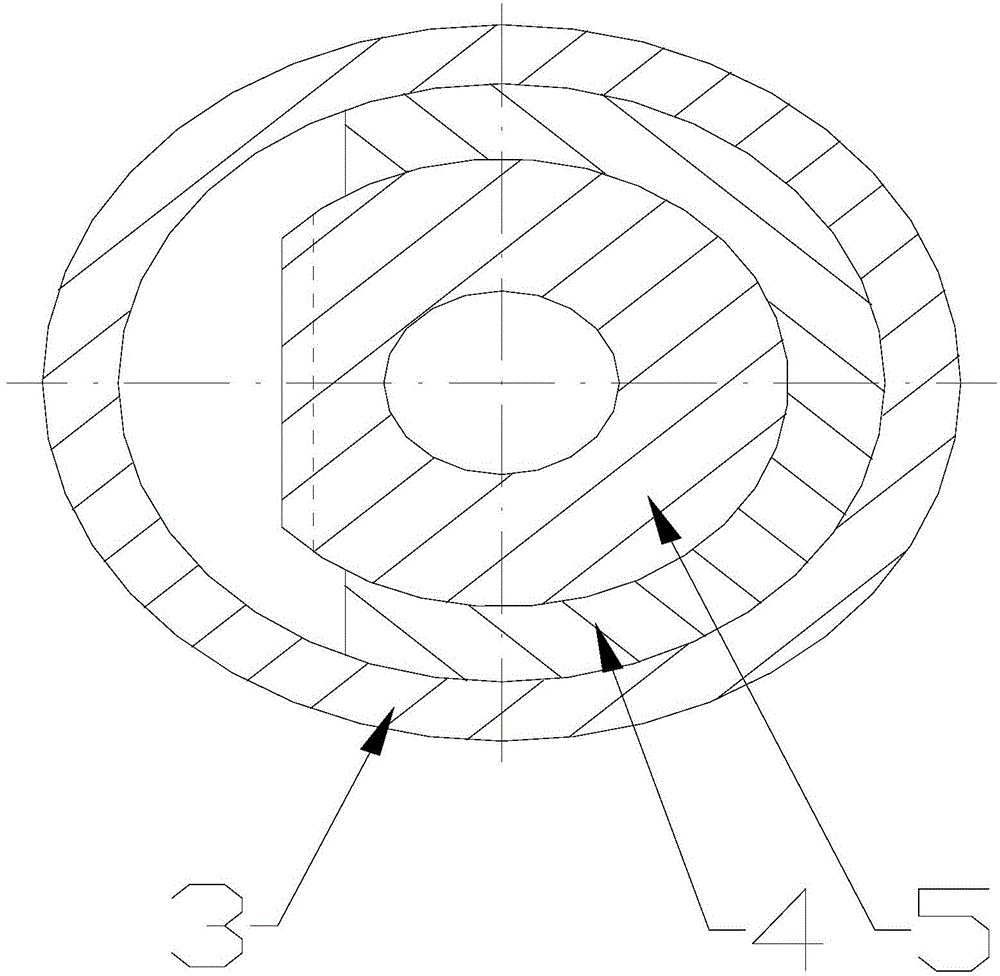

[0011] Depend on figure 1 combine figure 2 As shown, the linear drive pumping unit includes a base 1, the upper end of the base 1 is sealed with a flange connected to the pipe string 3, and the transition fit in the pipe string 3 is connected to the guide sleeve 4. The transition fit makes the guide sleeve 4 unable to rotate in the pipe string 3, ensuring that The opening position of the guide sleeve 4 faces the teeth of the rack 5, and the upper and lower ends of the guide sleeve 4 are provided with retaining rings 15 for holes to be fixedly connected with the pipe column 3 to fix the guide sleeve 4. The guide sleeve 4 is an opening where the solid part of the pipe exceeds a semicircle A section of cylinder, the inner hole of the guide sleeve 4 is matched with the outer cylindrical surface of the rack 5, the position of the opening side of the guide sleeve 4, the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com