U-shaped bottom-hanging type ash and slag melting treatment device

A melting device and ash technology, applied in the direction of combustion type, combustion method, incinerator, etc., can solve the problems of high melting cost and complex structure, and achieve the effects of wide application range, convenient operation and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further described in conjunction with the accompanying drawings and specific embodiments.

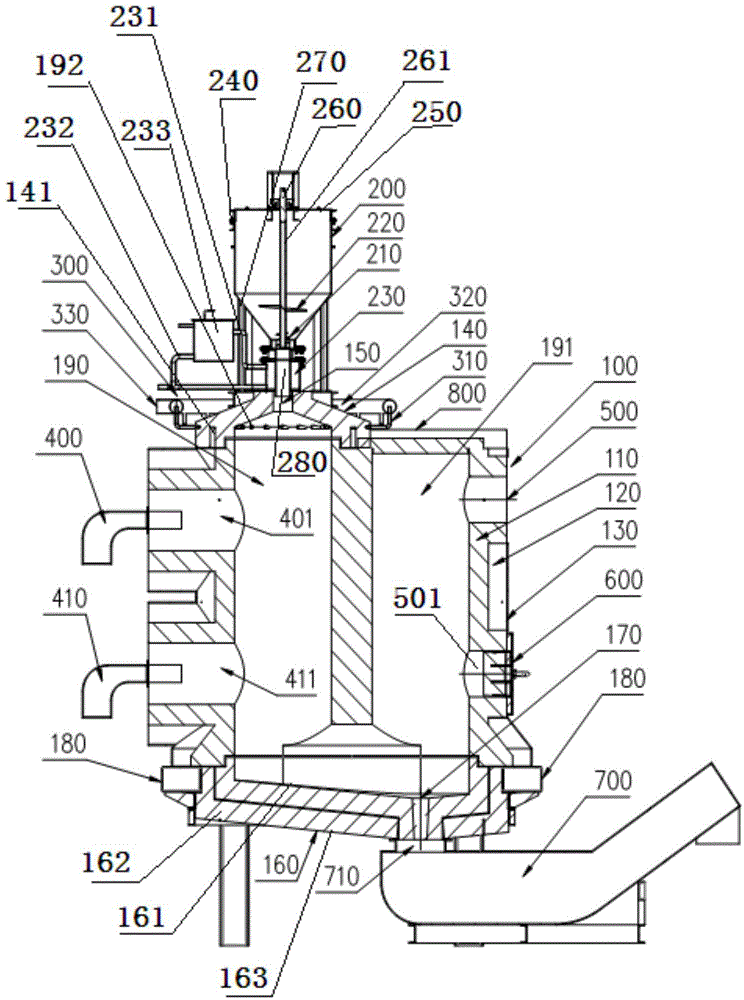

[0035] see figure 1 , figure 1 The U-shaped bottom-hanging ash melting processing device shown in the middle includes an ash melting furnace body 100, and the ash melting furnace body 100 includes a cylindrical front vertical furnace hearth 190 arranged at the front part of the ash melting furnace body 100 And the cylindrical rear vertical furnace 191 arranged at the rear of the ash melting furnace body 100; the cylindrical front vertical furnace 190 communicates with the bottom of the cylindrical rear vertical furnace 191 to form a U-shaped furnace.

[0036] Two flame passages 401, 411 are arranged on the front furnace wall of the front furnace 190, and the two flame passages 401, 411 are arranged up and down. The external port of 411 is docked.

[0037] A charging port 192 is arranged on the top of the cylindrical front vertical furnace 190 ; a furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com