Water-based protective coating for NTC thermistor temperature alarm and preparation method of the water-based protective coating

A technology for temperature alarms and protective coatings, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of physical and mental health hazards of coating workers, air pollution, etc., and achieve the effect of meeting environmental protection and intact solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method for a water-based protective coating for an NTC thermistor temperature alarm, comprising the steps of:

[0039] (1) According to the above ratio, take the deionized water in the formula and slowly add it to the mixing tank, and add the dispersant, leveling agent, first defoamer, substrate wetting agent, and pH regulator under the stirring state of 300r / min , the fungicide is then stirred at a speed of 500-800r / min, and dispersed for 10-30min;

[0040] (2) After reducing the speed, slowly add carbon black, modified aluminum phosphate, and zinc-free environmentally friendly anti-rust pigments under the stirring state of 300r / min. 1000r / min, stir for 25-35min, cover and soak for 4h, make it fully infiltrated, then transfer to a horizontal sand mill to start grinding, turn on circulating cooling water, control the grinding temperature not to exceed 40°C, measure with a scraper fineness meter, The fineness reaches 15-20um, and the grinding slurry is sen...

Embodiment 1

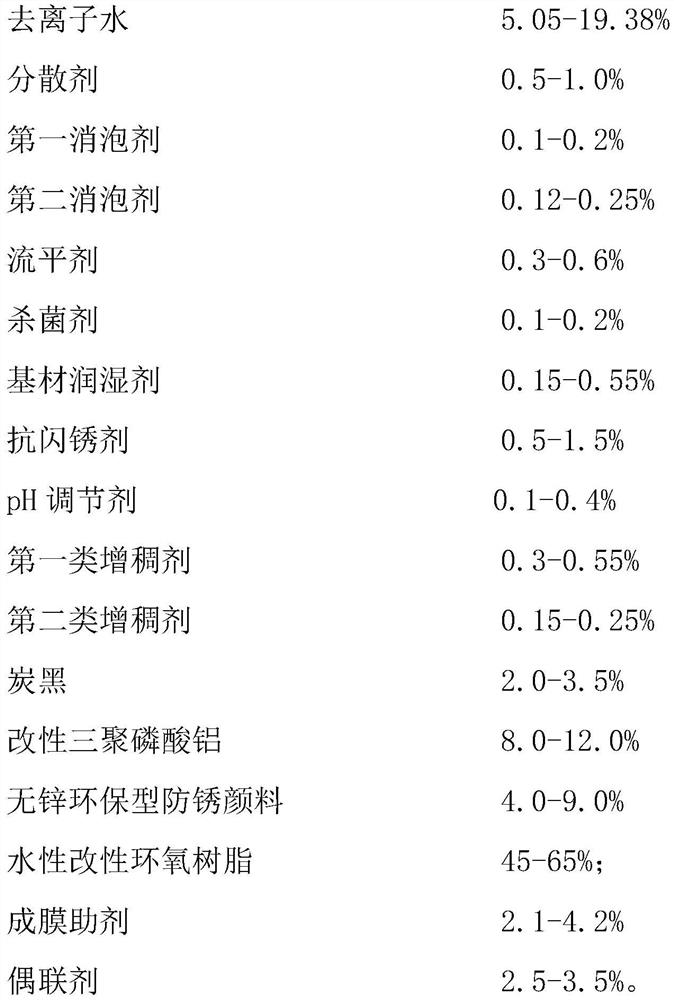

[0044] A water-based protective coating for an NTC thermistor temperature alarm disclosed by the invention comprises the following raw materials proportioned by weight percentage: 10% deionized water, 0.8% dispersant, 0.15% first defoamer, The second defoamer 0.21%, leveling agent 0.45%, bactericide 0.15%, substrate wetting agent 0.35%, anti-flash rust agent 1.0%, pH regulator 0.25%, the first type of thickener 0.45%, the second Type II thickener 0.2%, carbon black 2.8%, modified aluminum tripolyphosphate 10.0%, zinc-free environmentally friendly anti-rust pigment 7.0%, water-based modified epoxy resin 55%; Joint agent 3.0%.

[0045] The water-based modified epoxy resin is a self-emulsifying one-component modified epoxy resin, which can be self-crosslinked to form a film without matching a curing agent.

[0046] The first defoamer is a modified silicone defoamer, and the second defoamer is a modified polysiloxane defoamer.

[0047] The first thickener is a nonionic polyureth...

Embodiment 2

[0054] A water-based protective coating for an NTC thermistor temperature alarm disclosed by the invention comprises the following raw materials proportioned by weight percentage: 5.05% deionized water, 0.5% dispersant, 0.1% first defoamer, The second defoamer 0.12%, leveling agent 0.3%, bactericide 0.1%, substrate wetting agent 0.15%, anti-flash rust agent 0.5%, pH regulator 0.1%, the first thickener 0.3%, the second Type II thickener 0.15%, carbon black 2.0%, modified aluminum tripolyphosphate 8.0%, zinc-free environmentally friendly anti-rust pigment 4.0%, water-based modified epoxy resin 45%; Joint agent 2.5%.

[0055] The water-based modified epoxy resin is a self-emulsifying one-component modified epoxy resin, which can be self-crosslinked to form a film without matching a curing agent.

[0056] The first defoamer is a modified silicone defoamer, and the second defoamer is a modified polysiloxane defoamer.

[0057] The first thickener is a nonionic polyurethane thicken...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com