A large-pore pavement drainage capacity test equipment and method for simulating precipitation patterns

A technology that simulates precipitation and drainage capacity, and is used in permeability/surface area analysis, suspension and porous material analysis, measurement devices, etc. Pressure, not taking into account the influence of the size error of the specimen and the measuring cylinder, etc., to achieve a good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

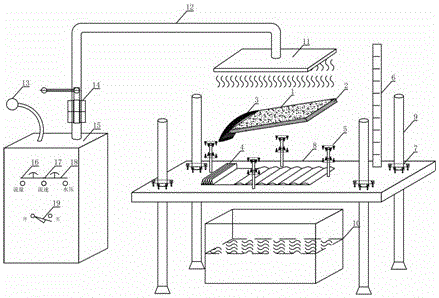

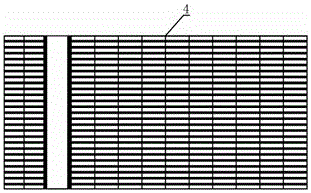

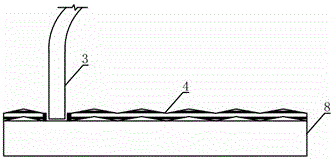

[0041] Embodiment 1: before the test, the wheel rolling method is used to form the rutting plate test piece 1, and the test piece removes the upper surface and a one-way side, and the four sides are coated with waterproof paint 2; open the simulated precipitation system switch; by adjusting the water temperature display controller 19, Set and keep warm the water temperature required by the test process, the temperature range is 1-25°C; adjust the water pressure display controller 18 to set the test required water pressure; adjust the flow rate display controller 17 to set the test required flow rate; adjust the flow rate display controller 16 to set The flow state is infinite; the test piece is fixed at the position by the test piece fixture 5, the inclination angle is required through the test, the height difference between the left and right sections of the test piece is calculated by using trigonometric functions, and the height is adjusted by the scale 6; the height of the t...

Embodiment 2

[0043] The difference between this embodiment and Example 1 is that the rut plate test piece 1 does not need to be coated with waterproof paint; the foldable telescopic plastic cover plate 4 is all folded and gathered to the left and right ends; Calculate the vertical drainage coefficient, through the formula Calculate the vertical drainage efficiency. Effectively measure the vertical drainage coefficient and vertical drainage efficiency of the specimen under different water temperature, water pressure, flow velocity, flow rate and precipitation height, so as to evaluate the vertical drainage capacity of the pavement under different rainfall forms.

[0044] In the formula: C 降 , is the precipitation coefficient; V 降 , is the total precipitation flow; t, is the test time; C 侧排 , is the lateral drainage coefficient; V 侧排 , is the lateral displacement; N 侧排 , is the lateral drainage efficiency; C 竖排 , is the vertical drainage coefficient; V 竖排 , is the vertical displac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com