Rapid aircraft fuel cleanliness detection method

A technology of aviation fuel and detection method, which is applied in the field of photon detection, can solve the problems of long analysis time, poor timeliness, and large workload, and achieves the effect of avoiding cumbersome procedures and having strong timeliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

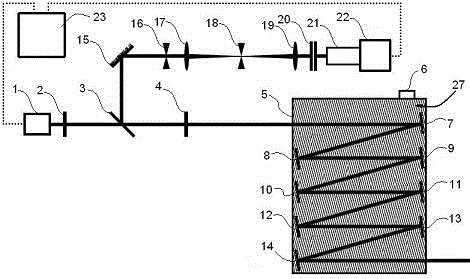

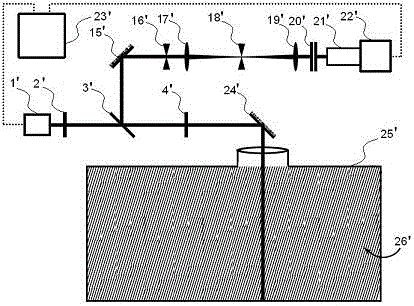

[0047] Example: figure 1 It is a schematic diagram of the device for establishing the cleanliness scattering data of pure aviation fuel 27. When establishing the cleanliness scattering data of pure aviation fuel 27, the consistency of the cleanliness of aviation fuel in the container must be considered. The small-volume glass tank is to ensure that the aviation fuel The key to the consistency of cleanliness, but the small-volume glass tank is difficult to meet the needs of long-distance optical path. Therefore, when designing the aviation fuel glass tank 5 (the distance between two opposite sides is 2m), in order to achieve the measurement of deep Brillouin scattering The signal avoids the inconvenience of making, using and storing the ultra-long aviation fuel glass tank 5. Multiple reflectors are used to make the laser reflect in the aviation fuel glass tank 5 for many times, so that the laser can be transmitted in a limited space and connected with the aviation fuel tank 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com