Electrowetting substrate, manufacturing method thereof and electrowetting display device

A manufacturing method and electrowetting technology, applied in the field of electrowetting, can solve the problem of low surface energy of the hydrophobic layer, and achieve the effects of improving service life, reducing manufacturing process, and stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

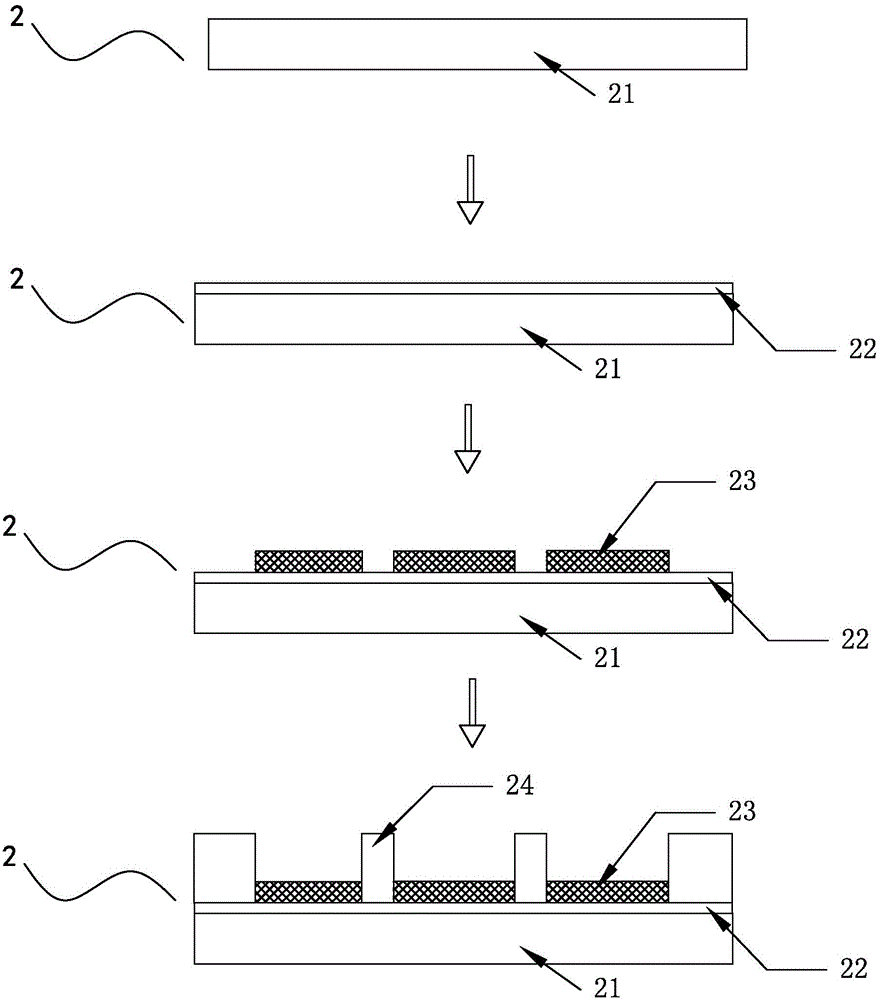

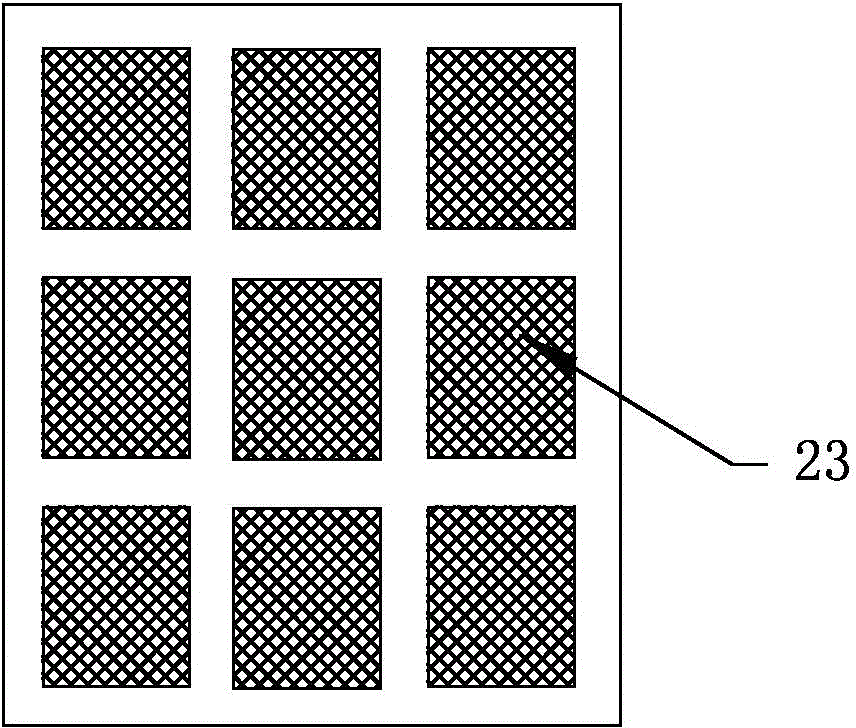

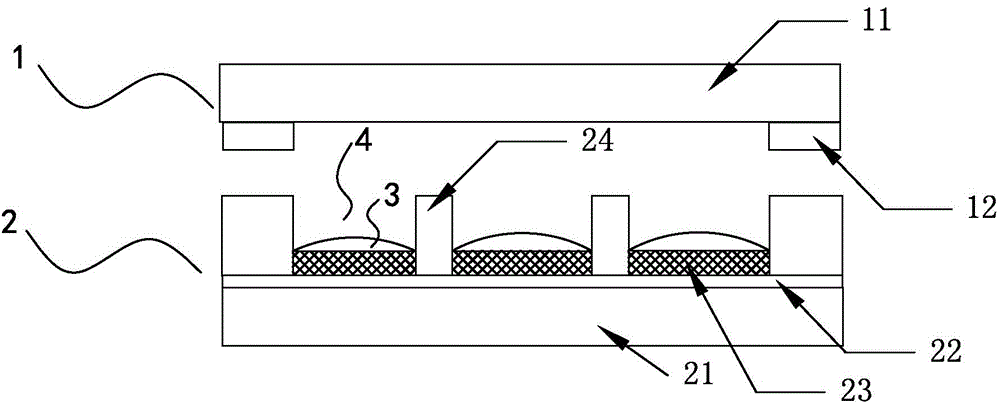

[0029] refer to figure 1 , the manufacturing method of the electrowetting substrate 2 with the pixel wall structure of the present invention comprises the following steps:

[0030] 1) Clean the conductive plate 21.

[0031] The conductive plate 21 can be a traditional conductive glass substrate, such as an ITO glass substrate, or a conductive flexible substrate, such as a PET substrate; the cleaned conductive plate 21 is dried at <120° C. for use.

[0032] 2) Deposit the insulating layer 22 .

[0033] This step is an optional step, which is selected according to the requirements of the electrowetting device for insulation performance.

[0034] The insulating layer 22 material can be silicon nitride (Si 3 N 4 ), silicon dioxide or Parylene, etc., wherein Parylene can be any of Parylene C, Parylene D, Parylene N, Parylene HT and other series products; LP-CVD (low pressure chemical vapor deposition) technology can be used at a relatively high Use vertical or horizontal tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com