Method of improving the interface performance of insulating layer and metal diffusion barrier layer

A technology of metal diffusion and insulating layer, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as damage to the dielectric layer, failure of the fabricated device to meet the process requirements, affecting the performance of dielectric layer insulation, leakage current, etc. , to reduce leakage current, improve huge losses, and improve bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

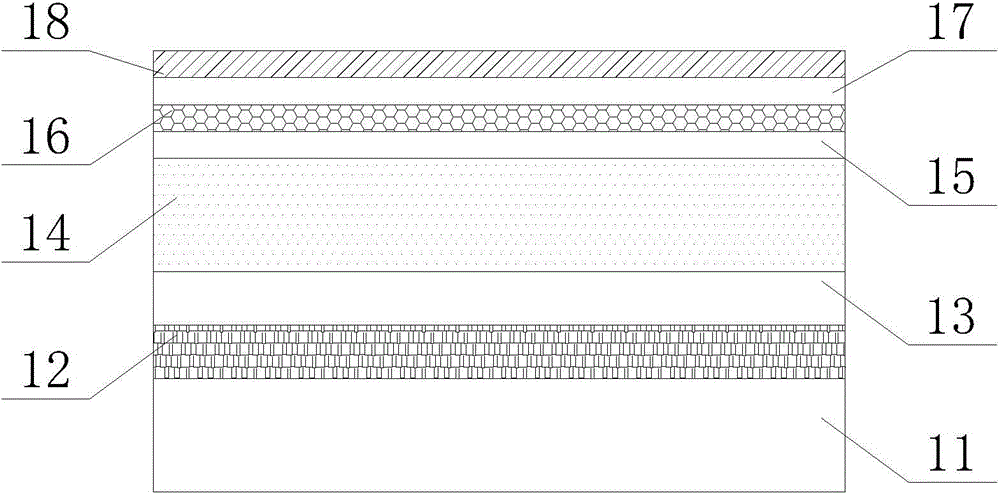

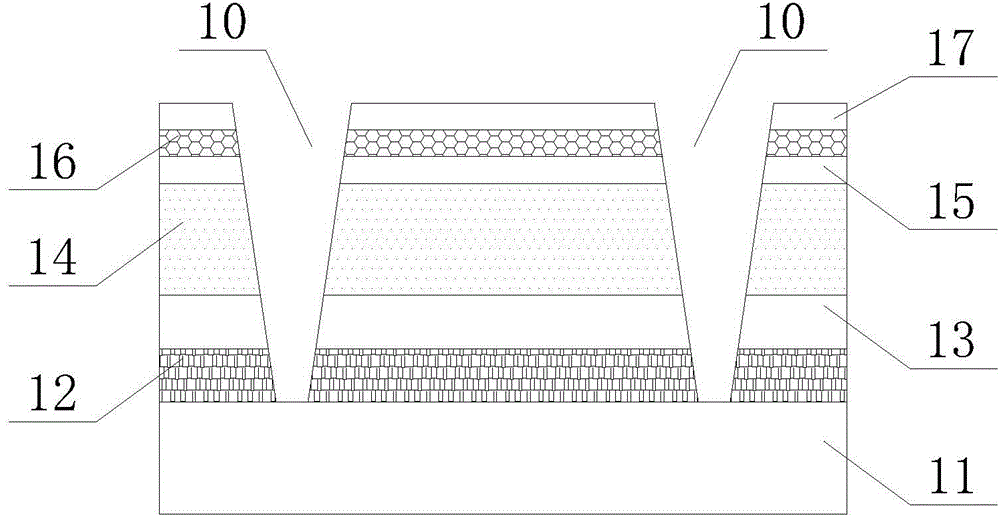

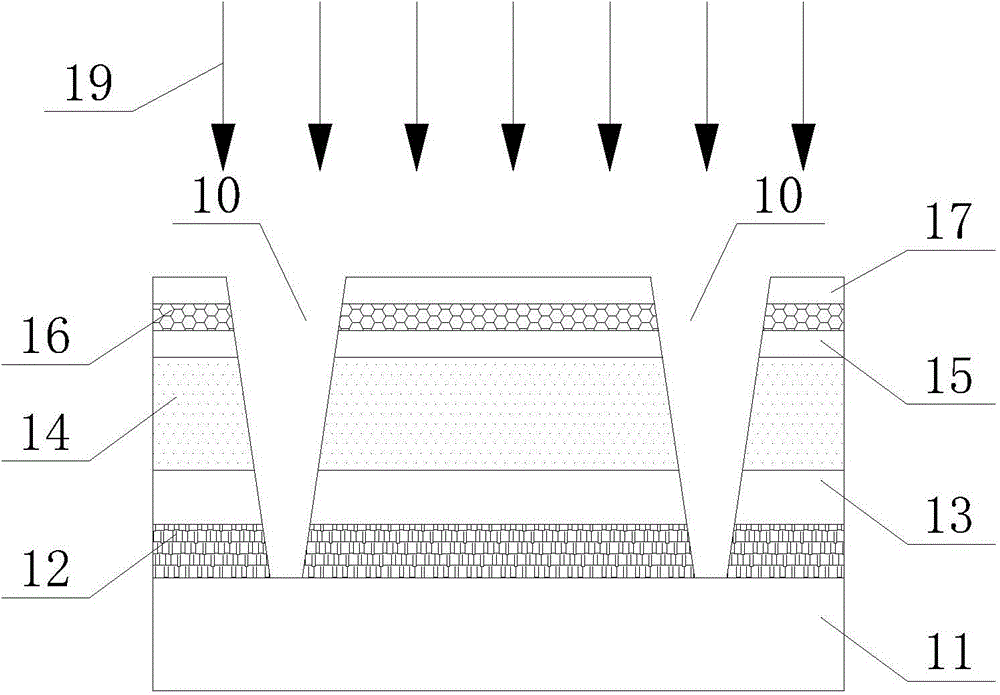

[0028] The present application relates to a method for improving the performance of the interface between an insulating layer and a metal diffusion barrier layer, which can be applied to insulating layers (such as dielectric layers with low dielectric constant (low k) and ultra-low dielectric constant (ultra low-k)) Prepare metal structures (such as metal interconnections, electrodes, etc.), and the material of the insulating layer can be an insulating material containing silicon (such as silicon oxide can be SiO 2 Wait).

[0029] When preparing a metal structure in a carbon-containing insulating layer (that is, an insulating dielectric layer), it is necessary to etch the prepared carbon-containing insulating layer to form a groove structure (the groove structure can run through the above-mentioned dielectric layer, or stay in the dielectric layer middle), regardless of wet etching (wet etch process) or dry (dry) etching, or even the previous photolithography process (litho), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com