A bionic water vapor condensation and collection structure and its preparation method

A water vapor and condensate technology, which is applied in the field of bionic micro-nano manufacturing, can solve the problems of poor hydrophobic performance, limitation of water vapor condensation and collection structure performance, and difficulty in large-scale preparation of conical structures, so as to achieve good water absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

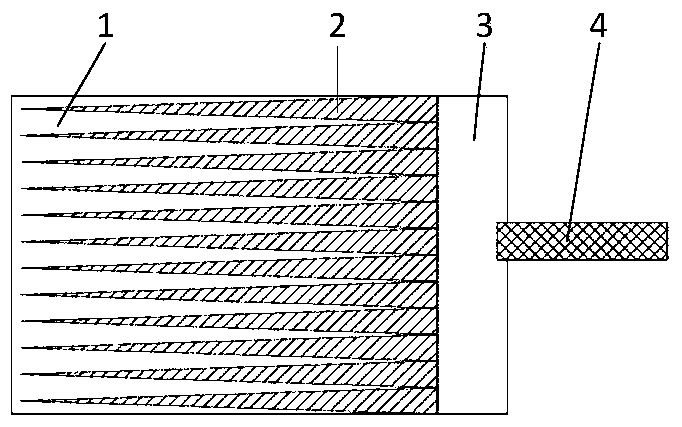

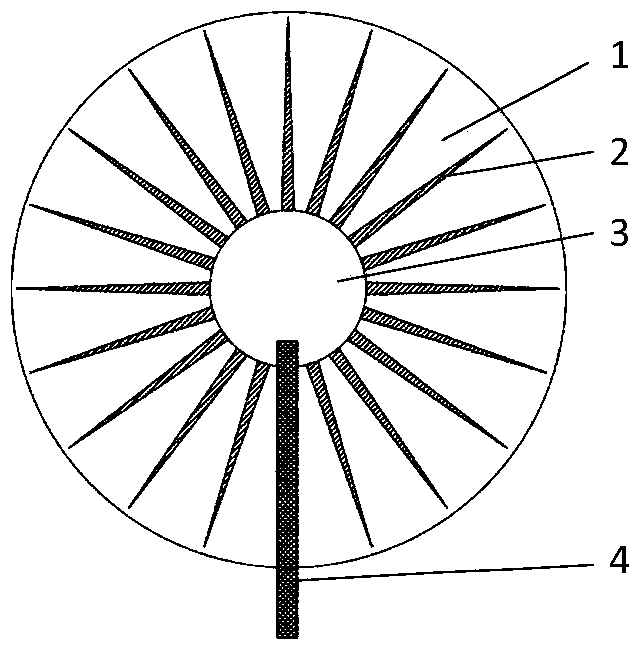

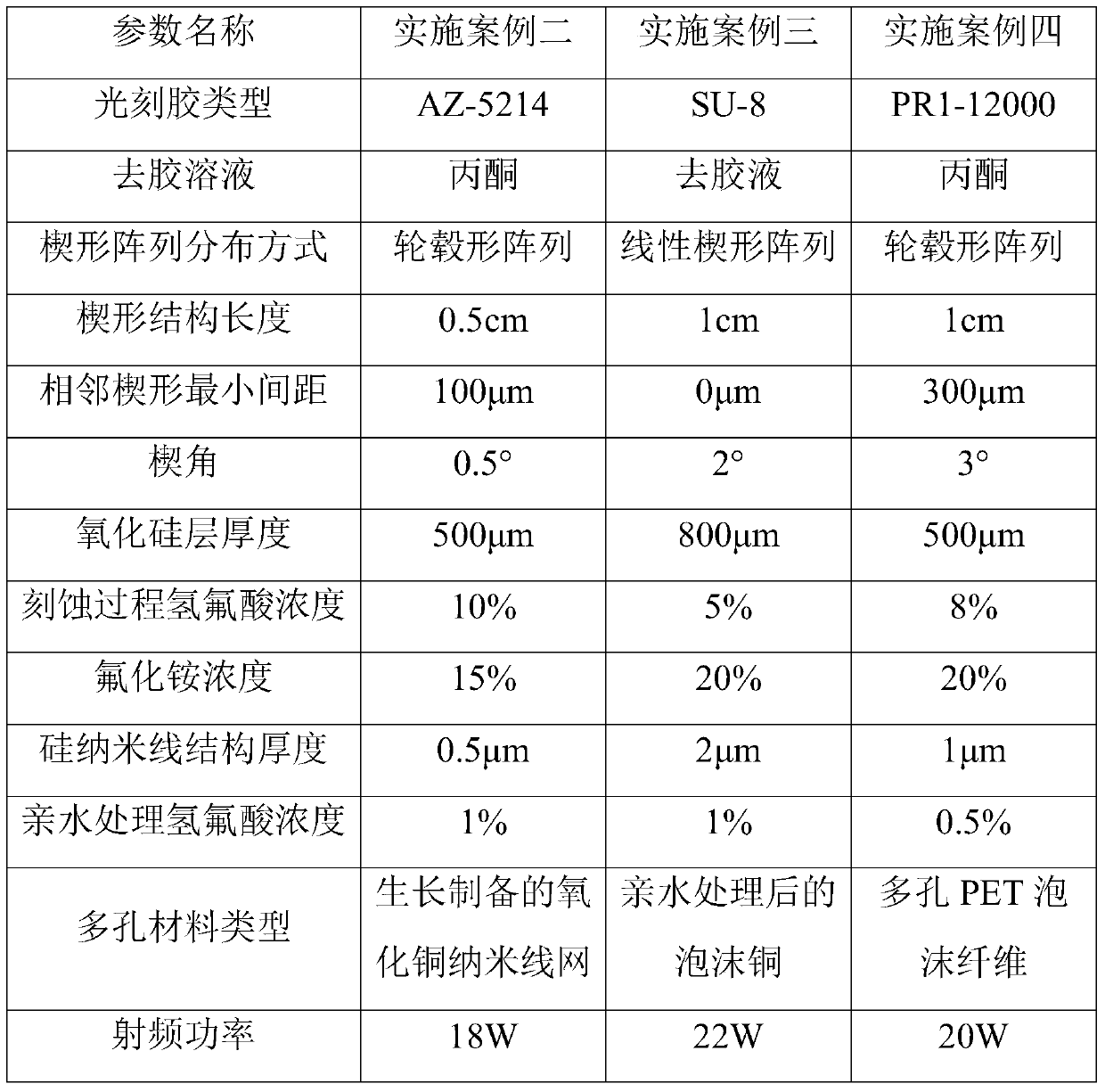

[0044] (1) Preparation of photoresist pattern: spin-coat PR1-1000 photoresist on the surface of the substrate, and expose and develop; wherein the substrate is a silicon wafer with a silicon oxide layer on the surface, and the thickness of the silicon oxide layer is 200; the prepared photoresist The resist pattern is a wedge-shaped array (2) and a condensate collection area (3). The wedge-shaped structures are distributed in a linear array. The length of a single wedge-shaped (isosceles triangle with a small apex angle) structure is 2 cm, and the distance between adjacent wedges is 200 μm. The angle is 1°;

[0045] (2) Etching the silicon oxide layer: using a mixed solution of hydrofluoric acid and ammonium fluoride to etch the sample prepared in step (1), so that the silicon oxide layer not protected by the photoresist is completely etched, and the silicon is exposed; The massfraction of hydrofluoric acid in the mixed solution is 5%, and the massfraction of ammonium fluoride ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com