Vertical shaft distribution and operation optimization design method for garbage landfill

A landfill and design method technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of inability to obtain collection efficiency, improve biogas collection efficiency, good adaptability and flexibility, and increase economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

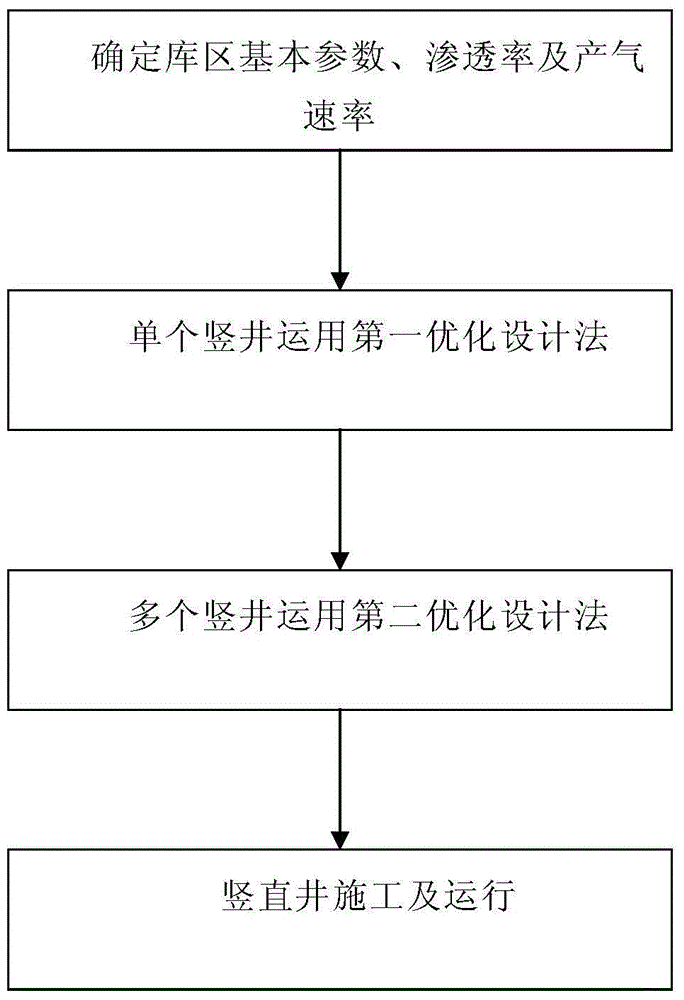

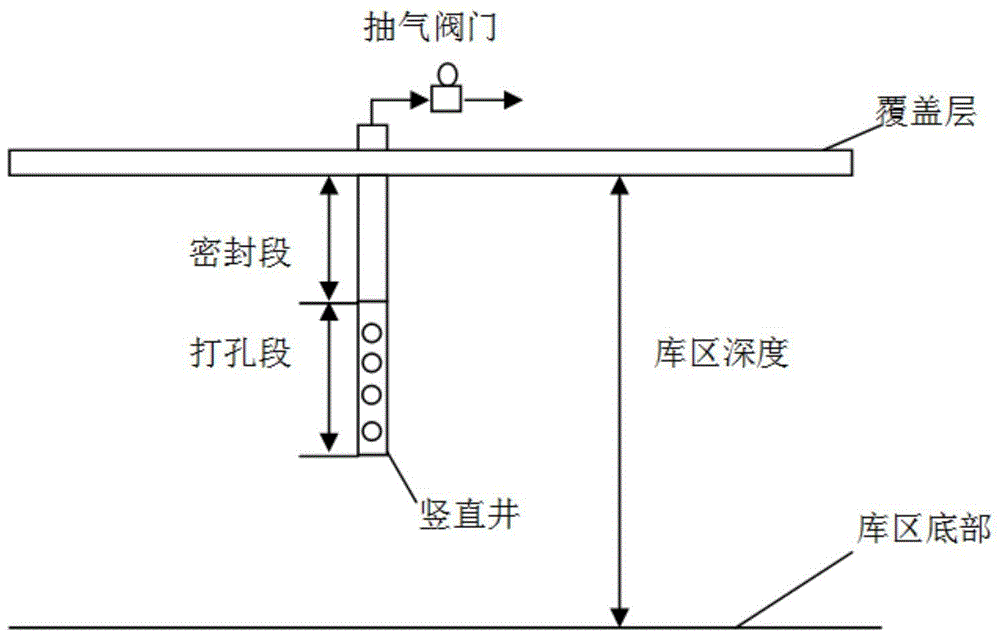

[0027] See attached figure 1 , a method for optimizing the design of shaft distribution and operation for landfills provided by the embodiment of the present application, comprising the following steps:

[0028] S1: Determine the basic parameters of the reservoir area where the shaft is located.

[0029] S2: Measure the permeability and gas production rate of the garbage dump in the reservoir area.

[0030] S3: According to the basic parameters, permeability and gas production rate, use the first optimal design method to calculate the gas pressure value of a single shaft, and at the same time, calculate the individual gas pressure values corresponding to different pumping intensities, perforation section lengths and permeability Describe the flow value of the shaft and establish a flow database.

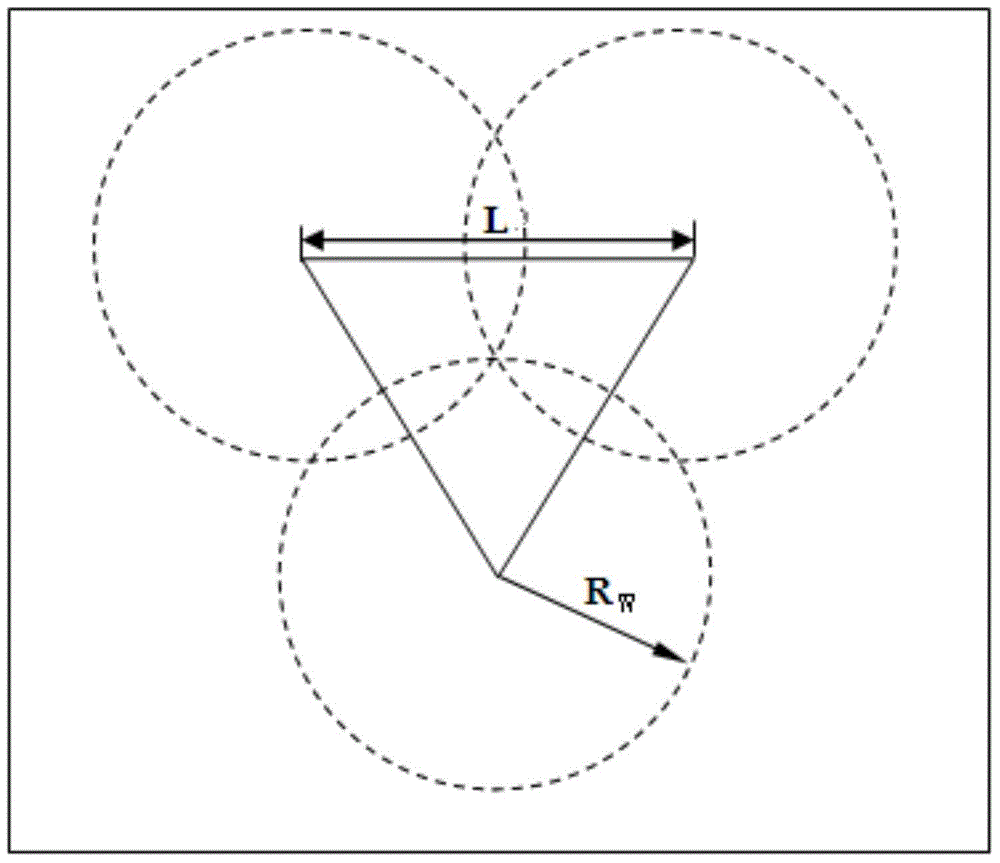

[0031] S4: According to the flow database, use the second optimal design method to determine the optimal well spacing, perforating section length and gas extraction intensity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com