Hemispheric lens matrix terahertz wave source with novel material structure

A lens matrix, new material technology, applied in semiconductor devices, semiconductor/solid-state device components, antenna supports/installation devices, etc., can solve the problem of limited power, structural limitations of single-tube terahertz wave sources, and difficult to achieve process conditions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A hemispherical lens matrix terahertz wave source with a new material structure of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

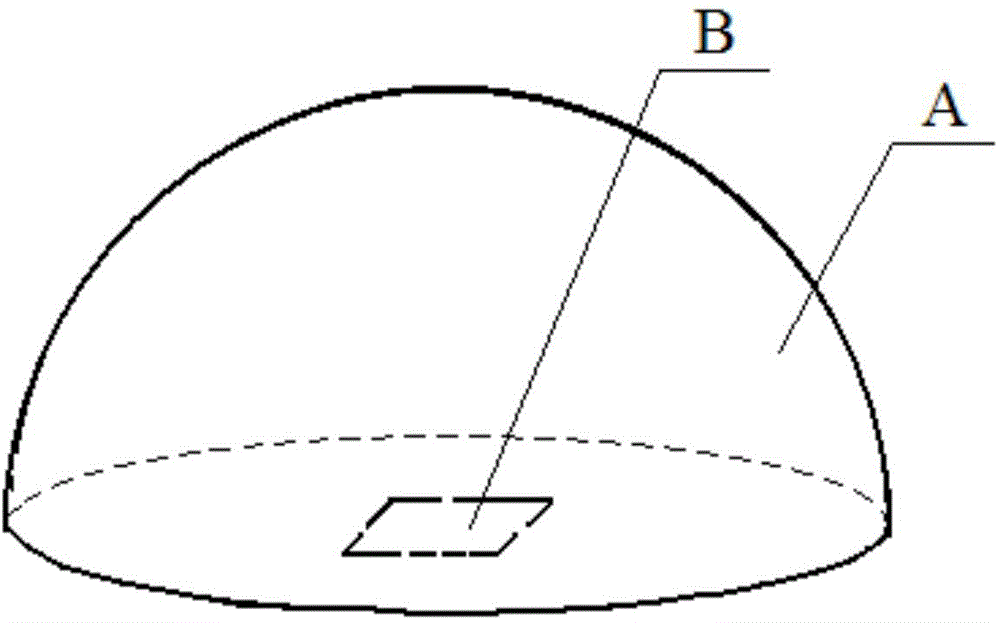

[0036] Such as figure 1 , figure 2 As shown, a hemispherical lens matrix terahertz wave source with a new material structure of the present invention includes a hemispherical lens A, and the lower surface of the hemispherical lens A is provided with an RTO matrix composed of a plurality of RTO emitting units B, that is to design a plurality of RTO emission units into an integrated array, and the RTO matrix B is located at the center of the lower surface of the hemispherical lens A. Considering the optimization of lead contact point layout derived from the bias voltage, etc., the RTO matrix B is a matrix composed of 2×2 to 32×32 RTO emitting units.

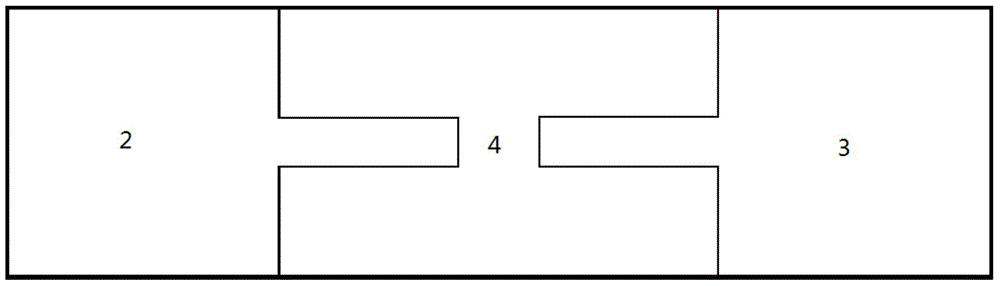

[0037] Such as image 3 , Figure 4 As shown, the RTO emitting unit includes an ultra-narrow double-well RTD devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com